Carbon Solutions

IHI, with its aim to realize a carbon neutral society, will provide, through its long-term track record and research development, carbon solution technologies. Through the years, IHI had developed and provided through its integrated technologies, highly efficient and reliable boilers, as well as providing carbon reduction solutions to achieve higher efficiency and operation of existing power plants. In addition, IHI also provides boilers and flue gas equipment for a wide variety of fuels such as biomass fuels and waste fuels to both domestic and international markets and is working towards social implementation of carbon capturing and utilization technology and ammonia combustion technology. Through its various technologies, IHI will provide various solutions towards the realization of a carbon-free and recycling society.

Carbon Solution Technologies

-

Ammonia is gaining attention as an energy carrier to achieve a carbon free hydrogen value chain.

Ammonia Combustion Technology

IHI has focused on ammonia, which has already developed infrastructure in place and can easily be sea transported, and have been developing technologies that would allow boilers to co-fire pulverized coal with ammonia.

IHI will be actively involved in the development of the value chain by further development of this technology and actual implementation. -

IHI contributes to the realization of stable electricity supply and environmental impact reduction by using biomass, a carbon neutral resource, as fuel. IHI's biomass related technologies such as highly efficient biomass co-firing/fuel conversion of existing coal fired boilers, biomass fuel conversion of heavy oil/crude oil-fired boilers, and construction of new biomass power plants, has been highly acclaimed and has led to IHI gaining several domestic experiences.

Biomass Combustion Technology

-

Carbon Recycling is a technology for capturing and utilizating CO2. IHI has been developing the technologies to separate and capture CO2 from exhaust gas and convert it into valuable products, such as e-methane carbon neutral city gas, Sustainable Aviation Fuel (SAF), and lower olefins. IHI also provides the solution to secure H2 as material for conversion of CO2-to-valuable products.

Carbon Recycling Technology

-

Methanation is a technology to convert CO2 into e-methane (carbon neutral CH4) through synthetization with H2. E-methane is available to existing infrastructure related to LNG supply chain continuously, because its component is nearly closed to city gas. Core technologies for methanation process are catalyst and reactor. IHI provides not only methanation system, but also solutions related to secure e-methane supply chain.

Methanation technology

Operation & Maintenance Service

-

IHI provides an advanced operation and maintenance support system (MEDICUS NAVI) using information and communications technology, that enables improvement on operation monitoring and lifetime assessment of boilers as well as optimization and manpower reduction needed for maintenance planning. IHI plans to further develop this system by implementing AI technologies to provide a more sophisticated operation support system services to enable optimization of environmental equipment control and combustion conditions, load change improvements, and minimum load reduction.

Operation & Maintenance Support System(MEDICUS NAVI)

-

IHI not only provides equipment but provides one stop operation and maintenance (O&M) service as well. IHI supports stable operation of power plants through long term service agreements for boilers such as equipment operation and daily/periodic inspection and repair works. In addition, IHI owns and operates its own biomass fueled power plant and will implement knowledge gained for further improvements in its O&M service.

Operation & Maintenance Services

Highly efficient Boilers accommodating various fuels

-

IHI has a variety of boilers ranging from small or medium subcritical boilers up to large supercritical boilers that can accommodate various types of fuels and can meet the optimum conditions of owners. As a utility boiler manufacturer taking a major role in supply of stable electricity in the world, IHI has been making great efforts to meet the steam conditions required for improvement of plant efficiency. As a result, IHI has achieved the world's highest level of steam conditions and thermal efficiency. Recent efforts also focus on ammonia or biomass conversion (fuel conversion or co-firing) of existing coal fired power plants.

Power generating Boilers

-

IHI provides boilerswhich are used in various industries for the purpose of factory process as well as private power generation. IHI also provides boilers fully equipped with environmental pollution preservation facilities such as those that effectively uses the vacuum residue oil and gas, a by- products of oil refineries, to produce steam for the usage of power generation. IHI also provides fuel conversion (either as primary or co-firing) of existing plants for decarbonization.

Industrial Boilers

-

CFB can burn a variety of fuels under faster fluidizing conditions. CFB is mainly used in various industries for the purpose of factory process as well as private power generation and has recently been used for biomass power generation. IHI will use its knowledge acquired from its experience in burning a variety of fuels such as biomass, industrial waste, and low-grade coal for optimal design depending on fuel source.

Circulating Fluidized-bed combustion Boiler

-

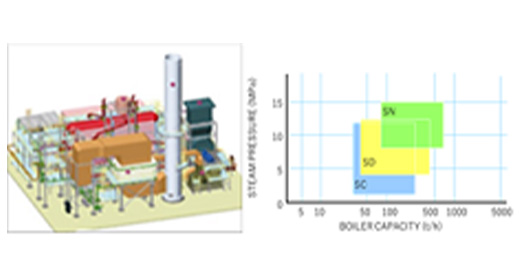

IHI provides boilers for a variety of applications globally including process plants, auxiliary boilers for large power stations, main boilers for small to medium power plans. These boilers are provided based on a proven standard design adjusted for steam volume. Additionally, based on our extensive boiler supply and delivery experience, IHI can optimize the boiler engineering and design to best meet each client’s individual specification.

Small to Medium Boilers(Package Boilers)

Air Quality Control Systems

-

Flue gas denitrification plant uses ammonium (NH3) and a catalyst to decompose nitrogen oxide (NOx) in exhaust gases. In flue gas desulfurization plant, sulfur oxide (SOx) from exhaust gases emitted from factories or thermal power plants is absorbed so that byproducts such as calcium sulfate can be recovered.

Flue Gas Treatment System(DeSOx/DeNOx Equipment)

Inquiries about products