(Atmospheric Bubbling Type Fluidized-Bed Boiler)

(Atmospheric Circurating Type Fluidized-Bed Boiler)

Fluidized Bed Boilers have the scope and ability to be applied in situations

where diversified fuel types are required, such as bitumous coal, lignite,

anthracite, petroleum coke, sludge, biomass fuel and so on. This is because

a fluidized bed has a large heat capacity and fluidization promotes an

excellent fuel/air mix. Furthermore, the fluidized bed boiler has the environmental

advantage of de-sulphurisation of spent fuels in the furnace and thereby

dispelling the need for a separate DeSOx plant. Also, because of its low

temperature combustion, there is no need for a DeNOx plant. An added advantage

is that there is no need for coal pulverizer as in a conventionally fired

boiler.

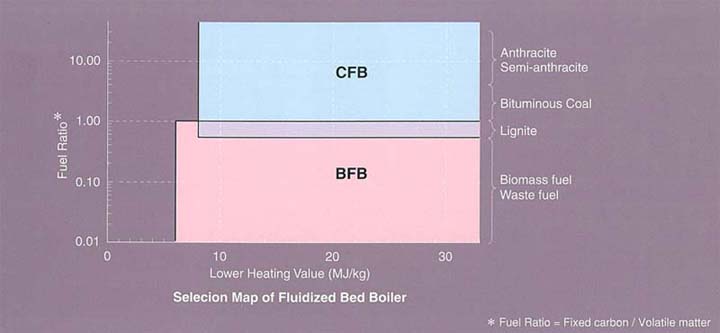

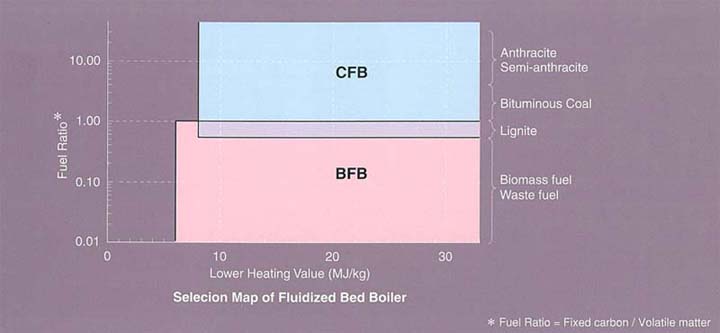

There are two types of fluidized bed boiler, bubbling type and circulating

type. The selection of type of fluidized bed boiler depends on the fuel

type, steam condition, etc.

BFB is suitable for fuel with low fuel ratio and/or low heating value such

as biomass fuel or waste fuel. On the other hand, CFB is suitable for fuel

with high fuel ratio such as anthracite, or for waste fuel firing under

the high steam condition.

IHI provides various types of fluidized bed boiler with a wide range of

capacity from small-scale process boiler to large-scale utility boiler.