DU has developed MF-Detector(Metal Fragment Detector) to meet the customers’ need for condition monitoring of the bearing area.

MF-Detector is an in-line metal particle counter for conductive particles such as copper, aluminum and white metal, and it enables early detection of abnormalities in the equipment by finding conductive particles.

And moreover, the combination of MF-Detector and TF-Detector, high sensitivity sensor to measure magnetic particles in liquid, provides total damage prevention by monitoring the lubricating oil.

【Other adaptable equipments】

・Condition monitoring of two stroke low speed marine engine bearings

・Condition monitoring of lubricating oil pump

・Condition monitoring of medium and high speed marine engines

・Condition monitoring of reduction gearbox (More effective when combined with TF-Detector.)

■MF-Detector main unit

|

■ MF-Detector monitor

|

|

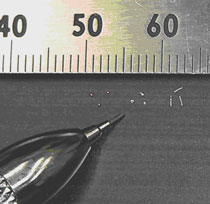

(Examples of detectable conductive particles) |

|||

|

||||

*The basic system of MF-Detector consists of the main unit and the monitor. The monitor with data logging function is available as an option.

We are trying to provide more improved products and services to give full satisfaction to all our customers.