Normally, a warehouse has aisles for storage and retrieval operations between racks, creating dead space when there are no such operations. By moving racks and setting up space for materials handling only when such operations are in progress, the dead space can be effectively used for storage. Aisles turn into storage space.

Mobile racks that can double or triple the storage capacity can be installed in both existing warehouses and newly built warehouses.

Warehouse management system

- >> Logistics systems TOP

- >> Materials handling / logistics equipment & Solutions

- >> Warehouse management system

Warehouse management system

IHI’s warehousing management system is a system software package that supports the management of logistics warehouses, inventory control, streamlined operation, and appropriate warehousing based on analyses, evaluations, and forecasts.

Warehouse management system

A wide range of technology and experience in everything from information systems to materials handling facilities is necessary to build warehouse management systems. IHI, as a comprehensive heavy industry manufacturer with extensive experience in system development, is the only company in the industry able to create the IHI-WMS (warehouse management systems). This system achieves a new type of warehousing, bringing fresh satisfaction to businesses.

IHI-WMS Standard (warehouse management system)

This software offers total warehousing support and helps businesses carry out efficient warehouse operation.

Reducing inspection errors

Wireless handy terminals (HT) read ITF codes, which are checked against the data for scheduled arrival, thus increasing the accuracy of inspections. Warehousing software monitors the incorrect arrival of items, incorrect number of items, and use-by dates (the software warns when use-by dates of items coming in are earlier than those of items that have already arrived.)

Simple control

Controlling the warehouse management system is plain and simple, which contributes to enhanced efficiency. IHI-WMS is a warehouse management system accessible to anyone, where displays that operators regularly handle use large fonts and are designed to reduce data-entry as much as possible.

Monitoring progress in real time

Warehouses face a variety of situations every day, such as increases and decreases in inventory, emergency shipments, and changes in orders. IHI-WMS enables real-time monitoring of progress that allows businesses to take quick and appropriate action.

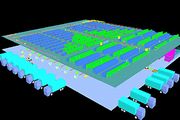

Linking logistics equipment with the warehouse management system

IHI offers materials handling equipment that matches each individual customer’s operation method and links it with the warehouse management system.

Metric inspection picking cart: Both scan inspections by JAN codes and metric inspections are available Receiving inspection cart: A wireless labeler is mounted on the cart, making it possible to conduct inspections anywhere.

IHI-WMS Enterprise (warehouse management system)

A warehouse management system that is even smarter than the standard warehouse management system. Only the required functions can be chosen.

Supporting optimum inventory levels

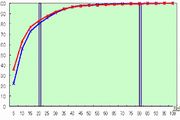

This system carries out ABC analyses of inventory based on operation history, thus identifying excessive or focus products. Optimum inventory allocation is carried out by assigning receiving shelves in a way that takes the ABC analysis into account.

Boosting productivity

Target operation time and operation time records are indicated based on individual operational history. Showing goals and achievements on the display increases the motivation of operators and improves operational qualities such as error and damage rates.

Identifying and reducing costs

The ABC analysis of logistics (activity-based costing) is the best tool for understanding operational costs. The measuring mode of the warehouse management system enables operators to easily measure their operation time (data needed for the ABC analysis of logistics), making the ABC analysis of logistics easier than ever.

Attendance management using the warehouse management system

Attendance management, which has previously been carried out separately from the warehouse management system using handwritten documents or timecards, can be completely digitalized by linking it to the warehouse management system.

Simulating warehousing operations

The warehouse management system can simulate operations for the next day based on tomorrow’s operation plan and today’s inventory. Operations that do not allow a second chance, such as changes in allocation of seasonal products, can be simulated with the warehouse management system to identify the influence of such operations beforehand.

The warehouse management system ensures traceability and verification

The warehouse management system extends the scope of traceability. It enables monitoring not only of processes within the warehouses but also processes leading up to the arrival of items at consignees.

Related page