Outline

With over 1500 units installed around the world,

we offer a variety of vacuum furnaces to suit our customers’ products and heat treatment processes.

Lineup

- Horizontal Vacuum Furnace

- Vertical Vacuum Furnace

- Multi-chamber Vacuum Furnace

- Vacuum Tempering Furnace

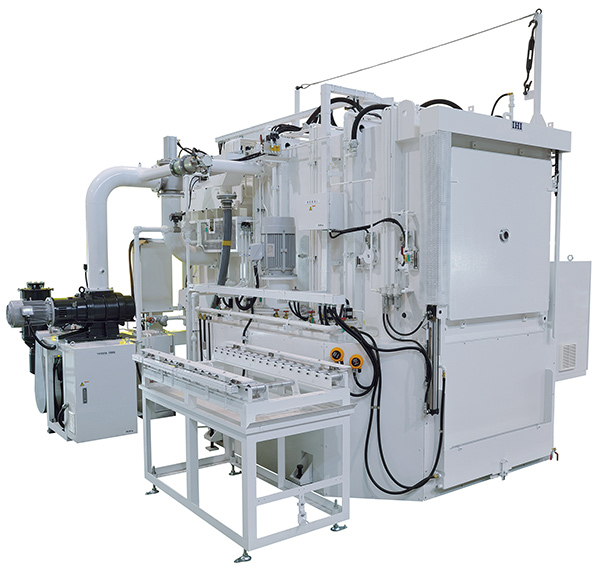

Outline

IHI invented new technology using acetylene gas and established the patents in 1996.

Lineup

- Vacuum Carburizing Furnace (VCB Type)

- Mass-Production Vacuum Carburizers (V-Cell)

- Multi-Chamber Vacuum Carburizing Furnace (V-MALS)

Outline

Hot presses are machines for pressurized formation of treated products in a high-temperature, vacuum environment. Ever since bringing out our first hot press in 1984, we have been developing and improving our line to meet customer needs for bigger sizes, higher surface pressure, and improved productivity. We can handle requirements in both of two application fields: sintering for formation of target materials, ceramics, and various electronic material substrates by filling graphite molds with powder, and diffusion bonding for bonding and formation treatment of metal, ceramic, compound materials, etc.

Lineup

- Hot press for bonding – single-axle type

- Hot press for bonding – multiaxis type

- Hot press for sintering

- Hot forming machine

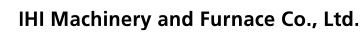

Outline

Removing and cleaning various oils (cutting oil, tempering oil, etc.) attached to the product before/after heat treatment

Lineup

- Vapor cleaning type

- Immersion type

- Cryo-drying & Vapor cleaning type

Outline

High temperature, high pressure and high vacuum furnace, epoch-making technology essential in future industrial world.

Lineup

- Graphitization furnace and refinement furnace

- Sintering furnace and combustion furnace

Outline

We possess 3 graphitization production facilities within Japan. We can meet specifications required by our customers and provide a wide range of temperature processing between 1,000°C and 3,000°C.

Suitable for the most advanced carbonization and graphitization processing such as graphite anode materials for lithium-ion battery.

Please feel free to contact us.

Lineup

- Sample test

- Manufacture by commissioning (graphitizing)

We pride ourselves with our flexibility towards a variety of customer needs.

Products on our website may not be sold or installed outside of Japan, due to the Japanese Foreign Exchange and Foreign Trade Law or any other laws of United States and other countries.