Demands for cleaner compressed air increase year by year, and oil free compressors have been desired more and more by various industries, especially pharmaceutical, food and beverage and electronics industries etc. who demand high quality oil free air in their plants.

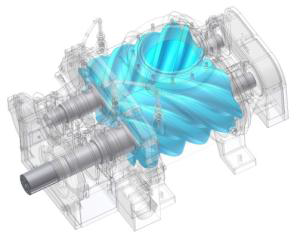

MZ series is outstanding Twin type air end for water injected screw compressor which use WATER for lubricant instead of oil and guarantees the compressed air is free of oil contamination.

Furthermore, it contributes compressor user to be environmental friendly which is more prioritized in company's activity nowadays globally.

| Type | Twin screw type | |||

|---|---|---|---|---|

| Model | MZ22A | MZ37A | MZ75A | |

| Motor power | kW | - 22 | - 37 | - 75 |

| hp | - 30 | - 50 | - 100 | |

| Driven | V-belt or Direct coupling | |||

| Discharge pressure | MPa(G) | 0.49 - 0.88(-1.0) *1 | ||

| bar(G) | 4.9 - 8.8(-1.0) *1 | |||

| Capacity *2 | m3/min | 0.76 - 3.21 | 2.10 - 5.66 | 3.42 - 12.35 |

| cfm | 27 - 113 | 74 - 200 | 121 - 436 | |

| Fluid | Air | |||

| Model | |||

|---|---|---|---|

| MZ22A | MZ37A | MZ75A | |

| Type of Air end | |||

| Twin screw type | |||

| Motor power | |||

| kW | - 22 | - 37 | - 75 |

| hp | - 30 | - 50 | - 100 |

| Flow rate | |||

| m3/min | 0.76 - 3.21 | 2.10 - 5.66 | 3.42 - 12.35 |

| cfm | 27 - 113 | 74 - 200 | 121 - 436 |

| Discharge pressure | |||

| MPa(G) | 0.49 - 0.88 | ||

| bar(G) | 4.9 - 8.8 | ||

| Fluid | |||

| Air | |||

Note)

*1 : 0.89 - 1.0Mpa(g) /8.9 - 10.0bar(g) is allowed only in the case of direct coupling drive.

*2 : At suction condition and discharge pressure 0.69MPa(G)

Water injected screw compressor is a next generation product which combines advantages of both an oil injected screw compressor and an ordinary two stage oil free screw compressor.

Instead of oil, the compressor uses water for lubrication. So water itself acts as lubricant and a sealing & cooling method.

Like oil injected screw compressor, it is mechanically simple, on top of that, the compressed air is OIL FREE.

- No oil mist and odors

- No disposal of drain included oil

- Cut the work load and cost of compressor user to take care of disposal of drain included oil

High efficiency and performance with energy-saving

- Water as lubricant helps to reduce pressure loss and keep high compression efficiency

Simple structure

- 1 stage machine, No timing gear

- Isothermal compression thanks to lubricate water

Minimum maintenance parts and low running cost

- Thanks to the simple structure

IHI MZ series air ends consist of water-friendly composite resin rotor, stainless steel shaft, copper alloy casing and other accessories designed for water injected screw compressors.

These highly reliable parts remove any concern about corrosion, and assure high performance of your packaged compressor.

Since we have launched our packaged water injected screw compressor in 2001 for the Japanese market, we have also expanded our business to sell air end itself to compressor manufactures all over the world and gained the trust and satisfaction of global compressor manufactures. IHI is one of the most successful company who develops twin type air end for water injected screw compressor and have numerous sales experience for a long period, since 2001.

By utilizing our MZ series air ends, you can expand your business to the new field and earn more reliability from your customer !

For more information, please contact us.