Paul Wurth IHI Co., Ltd., a 50-50 Joint-Venture corporation in the field of iron and cokemaking technology was incorporated in Japan in 2012 with the founding spirit to bring together the two partners on an equal footing.

Paul Wurth S.A., headquartered in Luxembourg, is a leading player in the global market for the design and supply of the full range of technological solutions for the primary stage of integrated steelmaking.

IHI Corporation, headquartered in Tokyo, is a Japanese manufacturer of heavy industries, having supplied a large number of blast furnaces in and outside of Japan.

Both companies have similar backgrounds: known to be high-technology and quality-oriented, offering a full range of globally proven products, and having similar company traditions, core values and long-term business perspectives.

Since its establishment, the Joint-Venture has been receiving orders mainly in Japan for coke oven batteries, coke oven machines and blast furnace auxiliaries such as pulverized coal injection, slag granulation and top charging equipment. Our market share has been significantly expanded by meeting the needs of our customers through tailor-made products and services which are based on our advanced technical know-how and the vast engineering, procurement and sales networks of both Paul Wurth and IHI.

We, Paul Wurth IHI Co., Ltd., will keep providing state-of-the-art technology worldwide from Japan.

Company Outline

- Company Name

- Paul Wurth IHI Co., Ltd.

- Head Office

- Toyosu Center Bldg. 9F, 3-3

Toyosu 3-chome, Koto-ku,

Tokyo 135-6009 Japan - TEL

- +81-3-6630-4785 (Representative)

+81-3-6630-4786 (Sales department) - FAX

- +81-3-3536-4014

Companies’ History

- 1870

Eugène Muller builds a boilermaking facility in Luxembourg Hollerich, known as Kesselfabrek.

- 1890

Paul Wurth takes over the firm, which specialises in metal erection works, especially the construction of metal bridges and blast furnace shells.

- 1951

Paul Wurth acquires from a British firm the licenses needed to supply complete blast furnaces with all the accessories.

- 1954

Construction of a first blast furnace at Seraing in Belgium.

- 1969

Invention of the Bell Less Top®, a revolutionary system for blast furnace charging.

- 1977

Internationalisation of the company with first subsidiary in Brazil.

- 2003

Creation of TMT Tapping - Measuring - Technology.

- 2004

Fabrication activities transferred to Arcelor Dommeldange. Paul Wurth becomes a pure engineering company.

Integration of Didier - M&P Energietechnik specialised in hot blast stove technology and refractory & lining concepts.

- 2005

Take-over of the blast furnace, coke making and direct reduction activities as well as the staff from SMS Demag S.p.A. and creation of Paul Wurth Italia S.p.A.

- 2009

A stake is taken in CTI Systems, specialised in intralogistics systems. In 2013, the company becomes a 100% daughter.

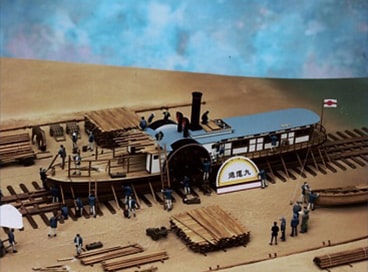

- 1853

The Ishikawajima Shipyard, the matrix of IHI, was founded by Tokugawa Nariaki, the fief of Mito. (the 6th year of the Kaei Era)

- 1890

IHI’s predecessor, the Ishikawajima Hirano Shipyard was established as Japan’s first privately managed Western-style shipyard.

- 1911

Steel Frame of Tokyo Central Train Stop (today’s Tokyo Station) was manufactured and assembled.

- 1940

The Kachidoki Bridge, a large bascule movable bridge was completed over Sumida River.

- 1952

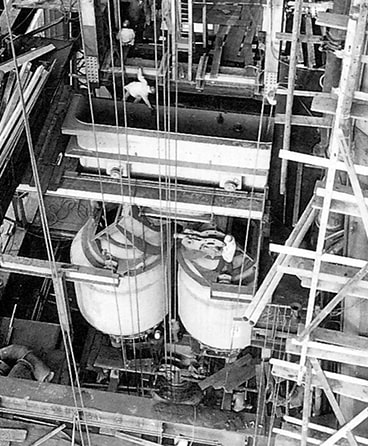

IHI supplied 907m3 Blast Furnace to Kawasaki Steel (Chiba). All welded furnace shell was first trial in Japan and IHI’s technology was conspicuous for its manufacturing and welding.

- 1959

Ishikawajima Do Brasil-Estaleiros S.A., a pioneer in the field of overseas investment by Japanese shipbuilding industries, was established.

- 1960

Ishikawajima Heavy Industries and Harima S&E merged and Ishikawajima-Harima Heavy Industries Co., Ltd. was inaugurated.

- 1972

IHI supplied 56 t/h coke dry quenching plant to Kawasaki Steel (Chiba), Japan.

IHI supplied 2656m3 blast furnace to Port Kembla, Australia.

- 1974

IHI made a license Agreement for Bell Less Top® with Paul Wurth.

- 2004

IHI supplied 5370m3 blast furnace to Sumitomo Metals (Kashima), Japan.

- 2007

Ishikawajima-Harima Heavy Industries changed the name to IHI.

- 2009

IHI supplied 3700m3 blast furnace to Sumitomo Metals (Wakayama), Japan.

- 2012

Creation of Paul Wurth IHI Corp., Ltd. in Japan.

- 2014

1st order for Coke Oven Pad-up and 1st order for Coke Oven Machine project in Japan.

- 2015

Major orders for Coke Oven Pad-up projects with Nippon Steel and JFE Steel, Japan.

1st order of several orders from Nippon Steel for PCI modifications.

- 2016-2018

Successful completion of Coke Oven Pad-up projects with Nippon Steel and JFE Steel, Japan

- 2018

Successful start-up by Paul Wurth of newly built CDQ plant in India. (Key technology supplied by PWIHI)

- 2020

Successful start-up by Paul Wurth of newly built CDQ plant in Russia. (Key technology supplied by PWIHI)

- 2021

-

Successful completion of Coke Oven Pad-up project with JFE Steel.

Successful completion of Bell Less Top charging system for blast furnace reline project at JFE Steel.

- 2021

-

Paul Wurth IHI started cooperating with SMS Group GmbH, headquartered in Germany, in the field of steelmaking including electric arc furnaces and melting and refining furnaces.

Access

- By public transportation

- Tokyo MetroDirectly connected with Exit 1b or 3 of “Toyosu” station, Subway Yurakucho Line.

- YurikamomeAbout 5 minutes on foot from “Toyosu” station, Tokyo Waterfront New Transit, Yurikamome.