|

WHAT

IS

SPB TANK?

SPB Technology .... The Highest Quality and Reliability in the World! |

|

|

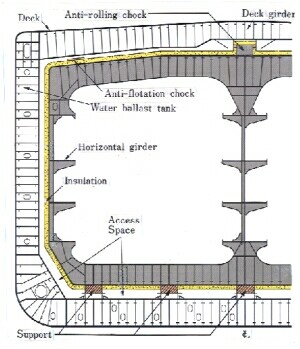

The tank is of stiffened plate structure of aluminum alloy or 9%Ni steel and covered by PUF insulation and supported by tank supports and chocks made of specially reinforced plywood. The tank is subdivided by a centerline liquid tight bulkhead and a swash bulkhead into 4 spaces. Because of this, natural frequency of the liquid inside tank is far from that of ship’s motion, eliminating any chance of resonance of the liquid cargo and ship two motions. Therefore no sloshing problem is expected and any level loading in tank is always possible. This enables partial loaded voyage, quick dispatch from the berth in emergency, and this makes SPB best suited to FPSO ,FSRU etc. in which tanks are always half loaded. Because of the nature of stiffened plate structure, the tank has the same strength against inner and outer pressure.

|

|

SPB does not need differential pressure control between hold space and tank, while membrane and moss are weak against outer pressure and differential pressure control is essential to them. Moreover, the hold space is used as inspection space facilitating inspection and maintenance. Consequently, SPB has plenty of advantages as follows;

|

|