SEPARATOR / DEHYDRATOR

- TOP

- SEPARATOR / DEHYDRATOR

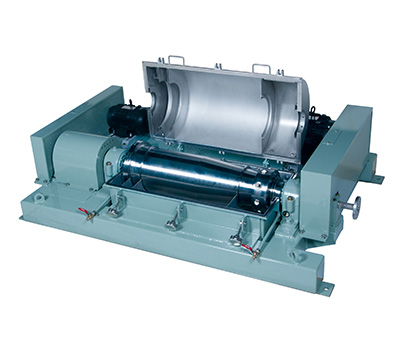

- PD Dehydrator

PD Dehydrator

Environment-friendly dehydrator with reduced vibration, noise, and odor

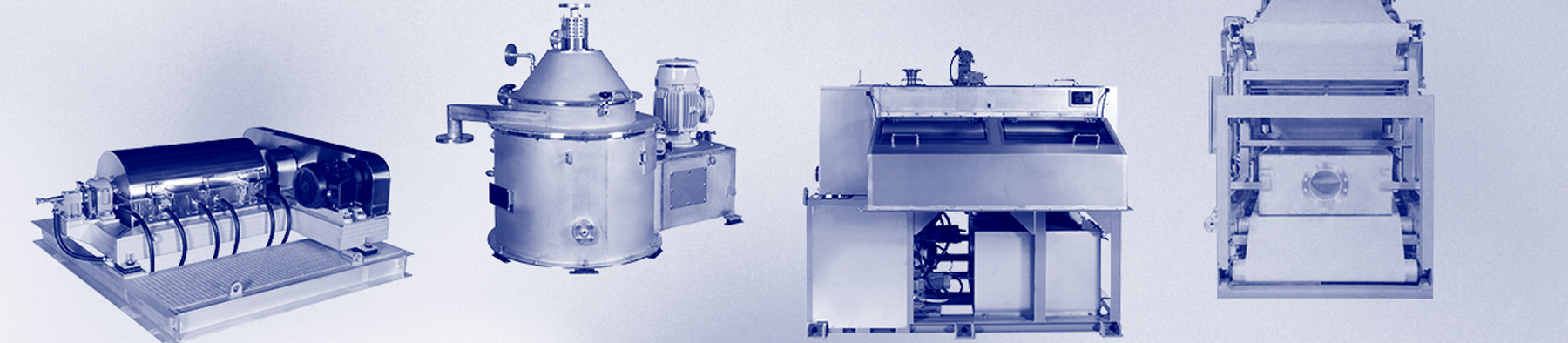

Based on our longstanding research on basic technologies, we have developed and added to our lineup one of the largest PD dehydrators in the industry. Up until now, treating large volumes of sludge required multiple machinery. With this new model, however, the process can be completed by a single machine. Moreover, IHI's unique and innovative filter element requires less power to operate, significantly contributing to energy efficiency.

- Economy

- 4

- Adaptability

- 3

- Specialty

- 4

- Dehydration capability

- 5

- AntiーWear

- 4

- Operation / Maintenance

- 5

- Total

- 25

Features

- Oil-containing wastewater dehydration capability

- Easy installation ideal for limited spaces

- Effortless maintenance

- Minimal washing water required

- Reduced vibration, noise, and odor

- Fully automatic operation

- Energy saving

Flow

The equipment within the broken line in the flow chart is included as a package. The slurry and flocculant are supplied into the flocculation tank, and the dehydrated cake is discharged from the cake chute while the filtrate is discharged from the filtrate outlet.

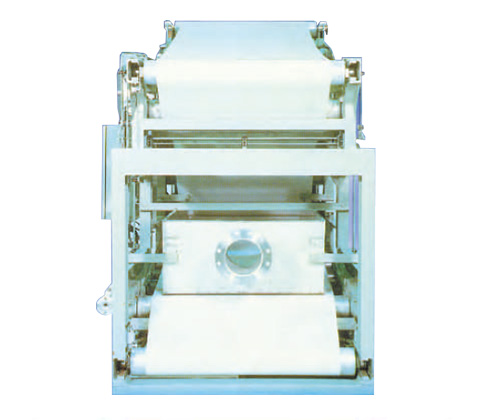

Operating Principle

- 1Separation and dehydration through gravity filtration

- Separation occurs through the fundamental principle of gravity filtration.

Filtration is done through the force of gravity, and does not require power from pressurizers or vacuums.

The filter medium, comparable to wire mesh and filter cloths, is a group of filter elements consisting of a combination of multiple thin discs and spacers.

Numerous cylindrical filter elements are integrated within the dehydration tank, securing a large Filtration area.

Flocs are captured on the filter elements to form a cake. Liquids flow downward through the gaps between the thin disc plates, and then, separated and collected before being discharged from the filtrate outlet.

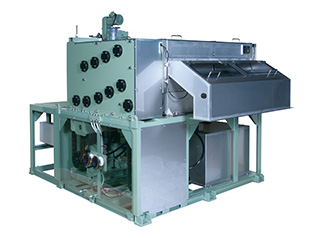

- 2Dehydration through drainage and consolidation

-

The group of filter elements gently rotate in a fixed direction. Cake formed by the flocs is transported over the filter elements towards the cake outlet, eventually exposing it above the liquid surface. Through the drainage effect, the water content of the cake is reduced. During this time, the rotation frequency of the filter elements placed directly before the cake outlet is lowered one notch to induce cake consolidation and promote further dehydration.

Through these processes of drainage and consolidation, the dehydrated cake is pushed toward the outlet.

- 3Automatic renewal of filter surfaces through scraping of cake layer

- The flocs accumulated on the filter elements are automatically scraped away by the gentle rotation of the elements and transported towards the dehydrated cake outlet.

This system allows the filtration surfaces to be constantly refreshed to ensure the flow channel for the liquids and maintain an efficient filtration rate.

- 4Filter element cleaning

- The filtration surfaces are constantly refreshed through the mutual scraping action of the filtering elements. To ensure further cleanliness, the filters are periodically cleaned by spraying them with jets of pressurized water. This removes blockages in the filtrate passage and maintains the filtration capability.

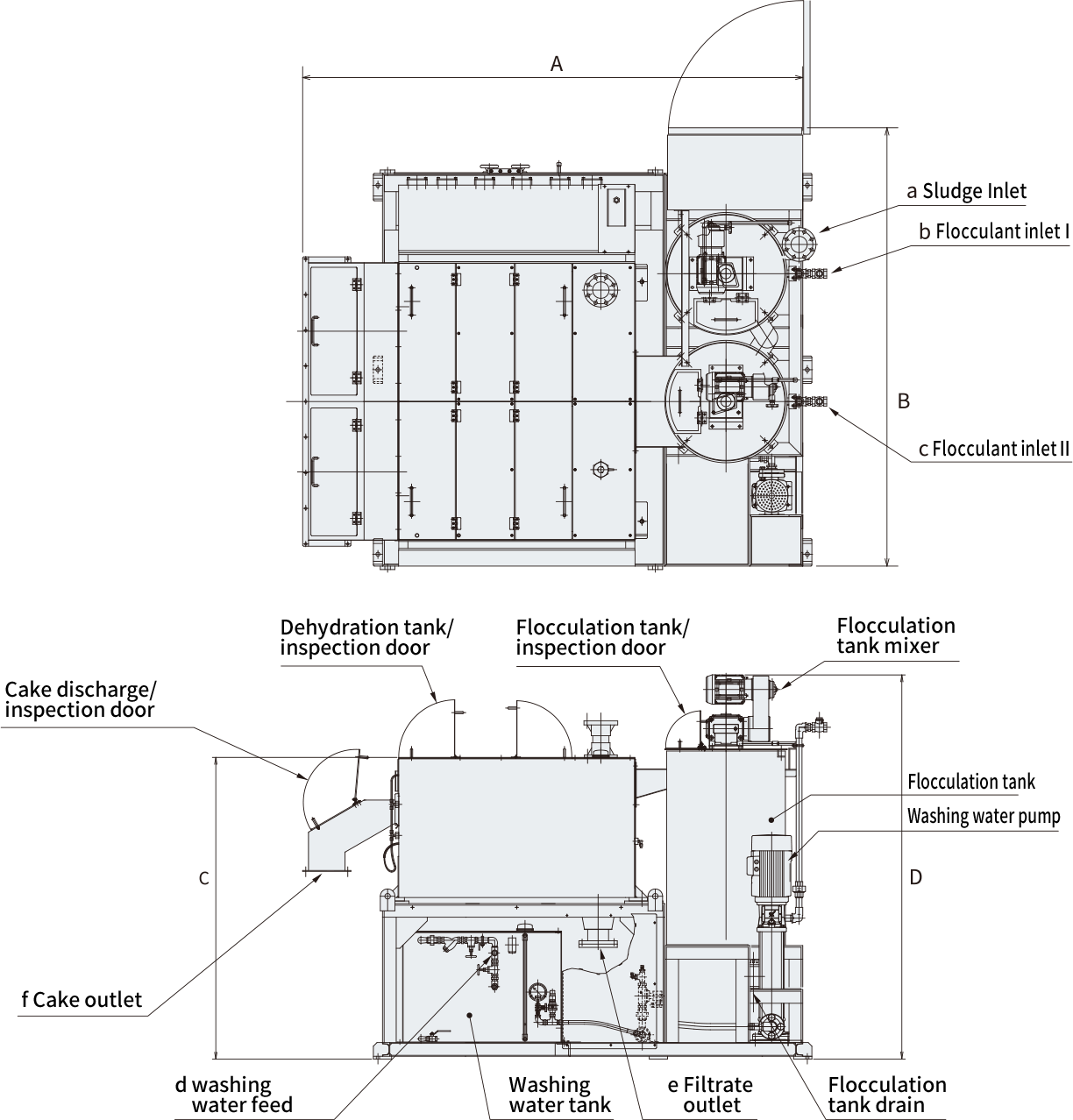

Dimensional specifications

PD-250Ⅱ~PD-2000Ⅱ

Specifications

| Filter width(mm) | Outward Size (mm) |

||||

|---|---|---|---|---|---|

| A | B | C | D | ||

| PD-250Ⅱ | 250 | 2647 | 1035 | 1540 | 1845 |

| PD-500Ⅱ | 500 | 2647 | 1120 | 1540 | 1845 |

| PD-750Ⅱ | 750 | 2647 | 1230 | 1540 | 1930 |

| PD-1000Ⅱ | 1000 | 2647 | 1480 | 1540 | 1930 |

| PD-1500Ⅱ | 1500 | 2737 | 2400 | 1652 | 2150 |

| PD-2000Ⅱ | 2000 | 2737 | 2650 | 1652 | 2150 |

| Power output (kW) | Weight(Ton) When dry |

Washing water volume(m3/日) *1 |

|||

|---|---|---|---|---|---|

| Drive unit | Mixer | Washing water pump | |||

| PD-250Ⅱ | 0.4 | 0.2 | 1.1 | 2.00 | 1.0~1.5 |

| PD-500Ⅱ | 0.4 | 0.2 | 1.1 | 2.45 | 1.0~1.5 |

| PD-750Ⅱ | 0.6 | 0.4 | 2.2 | 2.85 | 2.0~2.5 |

| PD-1000Ⅱ | 0.6 | 0.4 | 2.2 | 3.10 | 2.0~2.5 |

| PD-1500Ⅱ | 1.15 | 0.75×2 | 3.0 | 5.40 | 3.5~4.0 |

| PD-2000Ⅱ | 1.15 | 0.75×2 | 3.0 | 6.50 | 3.5~4.0 |

- Note 1: Washing water volume is calculated based on the amount required for six minutes of washing every hour for ten hours in one day.

About the evaluation criteria

About the evaluation criteria