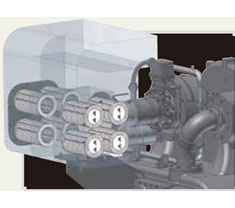

IHI centrifugal compressor is designed to be simple and reliable for easy maintenance, stable operation and maximizing uptime.

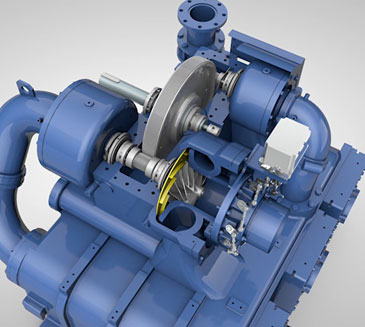

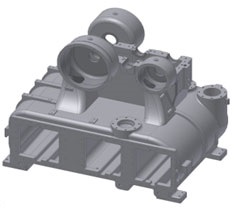

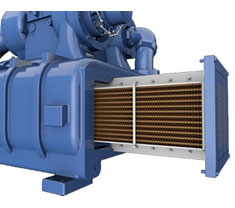

The gear case and air coolers are casted together in a single, robust and compact structure. The compressor unit and air paths are surrounded by a thick, seamless wall that is also highly effective in reducing noise levels.

The suction filter uses a cartridge type element, which allows for easy replacement.

To ensure the stable operation of the compressor, the coolers need to be cleaned periodically. The air coolers mounted on IHI centrifugal compressors are designed to allow water to flow along the pipes, and its simple structure makes cleaning very easy.

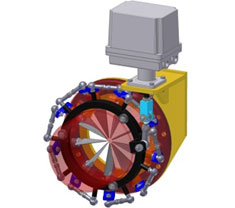

With the inlet guide vane(inlet throttle valve), air supply can be controlled in accordance with consumption. Further, the inlet guide vane enhances efficiency by providing preswirl flow to the air taken into the compressor in the same rotative direction as the impeller.

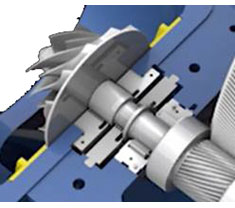

Tilting pad journal bearing, which realize high-speed and stable operation, are adopted. Pad tilt will change in accordance with bearing load changes, which provides excellent compliance with load change in the compressor.

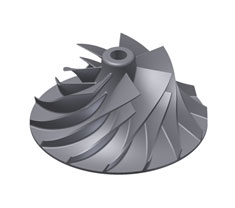

The three dimensional impeller, designed by making the fullest use of our extensive experience and cutting edge CFD technology, enables world top class efficiency and a wide operating range. The use of both titanium and high strength stainless steel means there is no need to worry about wear or corrosion.

The velocity energy imparted to air by the rotation of the impeller is efficiently converted into pressure energy by the diffuser. Because the impeller and diffuser are analyzed together using cutting edge CFD technology, air turbulence is kept to an absolute minimum, and operating noise is extremely low.

For the air seal and oil seal, the labyrinth type, which has no contact with the shaft, is adopted, so there is no wear resulting from operation and no periodic replacement is required.