IHI Rotating Machinery Engineering, as one of the leading rotating machinery manufacturers, is proud to present to you our internationally renowned rotating machinery technologies that has been similarly applied in different fields such as jet engines, turbo chargers and compressors.

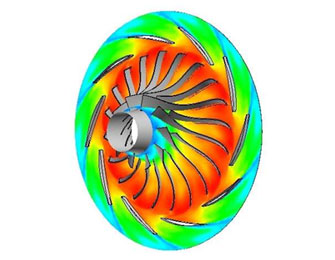

One of the main feature of IHI centrifugal compressors is “User customization” . IHI centrifugal compressor can offer optimal designs to meet the fluctuating air demands of your plant by combining more than 1,500 design of aero parts which is developed using Computational Fluid Dynamics (CFD) methods drawing from IHI’s extensive experience. IHI Rotating Machinery Engineering will always offer “your best compression solution”.

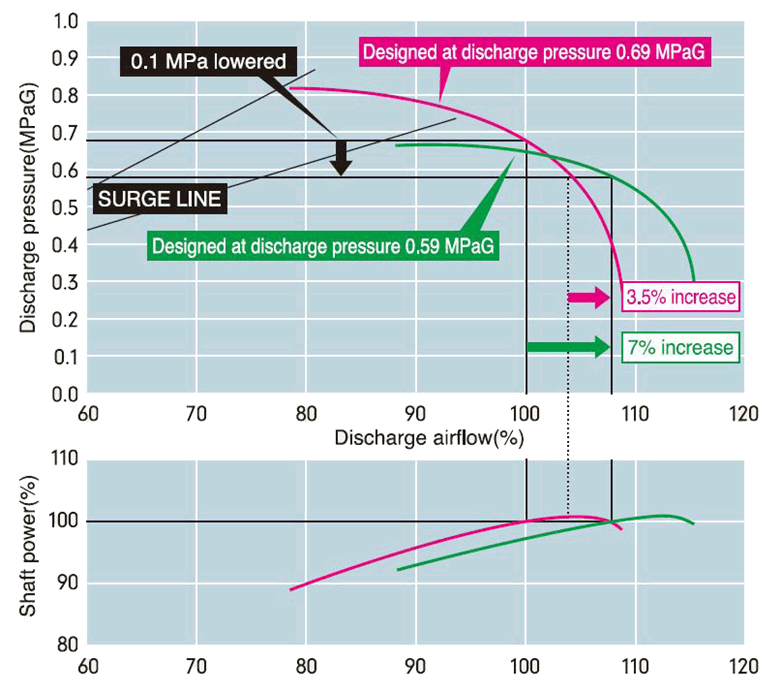

IHI centrifugal compressors are available in a wide range of variations to match the plant air pressure.

Discharge pressure 0.69MpaG(red curves in figures at right)

Discharge pressure 0.59MPaG(green curves in figure at right)

Case 1: discharge pressure 0.69MPaG compressor operated at discharge pressure 0.59MPaG

Case 2: discharge pressure 0.59MPaG compressor operated at discharge pressure 0.59MPaG

Compared with case 1, case 2 has an air flow increased of approx. 3.5%.

When compared with the same shaft power, the air flow increase is approx. 7%.

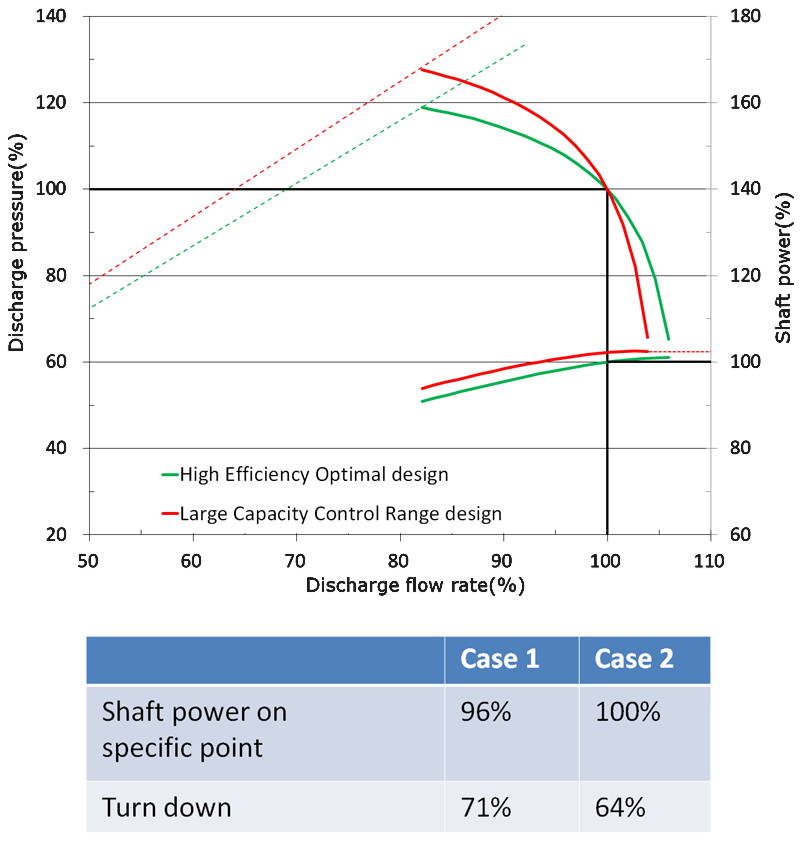

IHI centrifugal compressor allows you to select compressor’s aero design in accordance with the fluctuations of plant's air demand.

Case 1: The most efficient model on the specific point

Case 2: The model which has a wider turn down range.

Compared with case 2, case 1 has an lower shaft power on specific point by approx. 4%

Compared with case 1, case 2 has an wider turn down range by approx. 7%