The turbo compressor "TRZ" achieves both "High Efficiency" and a "Wide range." By adopting a new impeller and pinion bearing system, the TRZ delivers up to approximately 3.5% higher efficiency compared to existing models. In addition, it achieves about 15% increase in flow capacity, while maintaining high performance across a broad pressure range. These advancements significantly contribute to reducing both electricity costs and CO2 emissions at production sites.

| Motor Size | 500kW-1,120kW | ||

|---|---|---|---|

| Flow Rate | 5,600-12,320m3/h | ||

| Discharge Pressure | 0.5-0.95MPaG | ||

| Dimensions | Length | 4,700mm | |

| Width | 2,100mm | ||

| Height | 2,200mm | ||

| Weight | 11,700kg | ||

We have more than 1,500 aero parts design for the most optimized centrifugal compressors to meet customers' requirements. The aerodynamic design has been analyzed by Computational Fluid Dynamics (CFD) method, same as we use when designing jet engines and turbo chargers.

By supplying the most suitable centrifugal compressors , IHI can contribute to energy saving for your plant, as well as reducing life cycle cost dramatically.

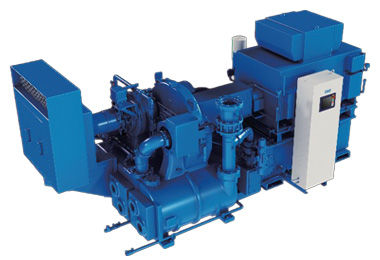

TRE series consists of vital components, such as air cooler, main motor, control panel, gear box, suction filter and all these will be fitted into one compact package. This simple design allows for smaller installation space and shorter installation time. The structure of the robust gear box provides the customers with high reliability by utilizing tilting pad journal bearing, customized core parts(Impeller, diffuser). These parts are designed with anti-wearing technology, built for long life and stable operation.

IHI centrifugal compressors supply 100% oil free air to the customers. They are classified under the latest ISO8573-1 Class 0 oil free, which is the highest grade for the purity of compressed air, by an independent third-party test house TÜV in Germany, minimizing the risk of oil contamination.