Spacecraft Propulsion Products

IHI Aerospace is the leading manufacturer of propulsion systems in Japan

and has been developing and manufacturing spacecraft propulsion systems since 1964.

We offer monopropellant, cold-gas, bipropellant

and electric propulsion systems with flight qualified products for satellites and rockets.

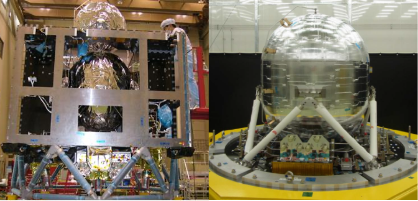

Spacecraft Propulsion Systems

Our spacecraft propulsion systems have been used in a wide range of missions for over 40 years. IHI Aerospace has developed and built over 100 propulsion systems as well as its thrusters and tanks.

Our propulsion systems have been used for:

- ●Orbit control and reaction control of spacecraft including H-II transfer vehicles (HTV)

- ●Reaction control of launch vehicles

- ●Control for re-entry capsules.

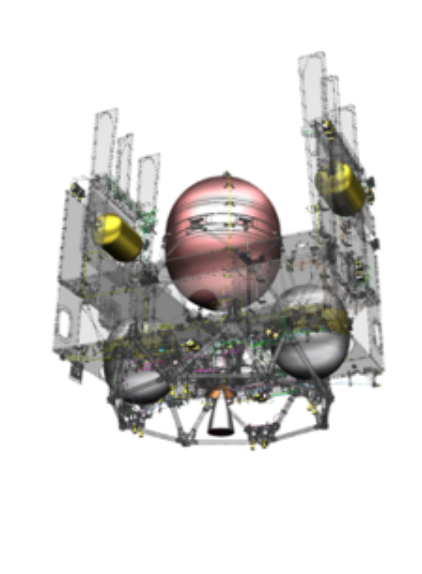

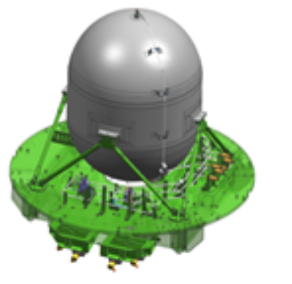

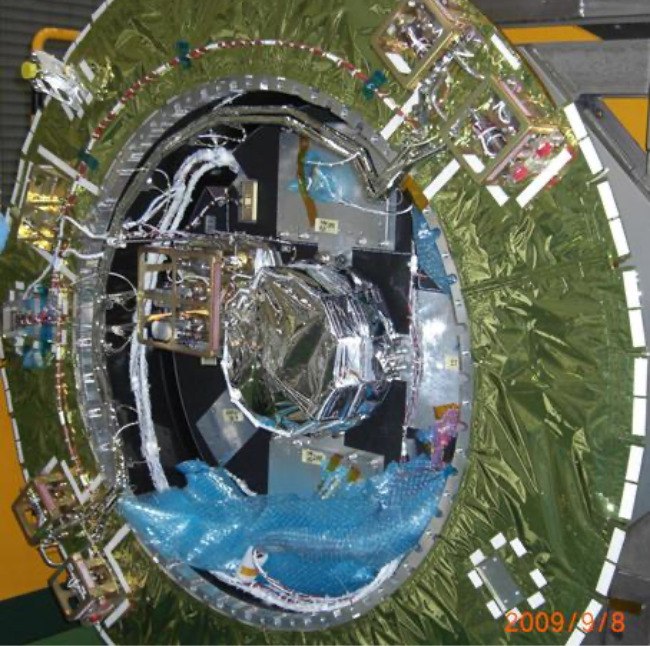

Bipropellant Propulsion Systems

IHI Aerospace developed and manufactured bipropellant propulsion systems with hydrazine N2H4 and mixed oxides of nitrogen MON3 since1980s. These systems have a bipropellant apogee engine and monopropellant thrusters for reaction control. We have also developed and manufactured bipropellant propulsion systems with mono methyl hydrazine MMH and MON3. The MMH/MON3 bipropellant propulsion system has been used for H-II Transfer Vehicles (HTV). The HTV propulsion system is equipped with four main thrusters and fully meets the safety requirements of the ISS.

| Program | Launch Year |

Orbit | Propellant Load [kg] |

Thruster Configuration |

|---|---|---|---|---|

| UNAR-A | cancelled | Lunar orbit | N2H4 :143 NTO: 49 |

500N main engine, 20N x 6, 1N x 4 |

| ETS-VI | 1994 | GEO | N2H4 : 910 NTO: 825 |

1700N main engine. 50N x 4 |

| J-I EVE | 1996 | Launcher | N2H4 : 126 NTO : 120 |

3600N main engine |

| COMETS | 1998 | GEO | N2H4 : 1030 MON3 : 840 |

1700N main engine. 50N x 4, 1N x 16 |

| DRTS | 2002 | GEO | N2H4 : 973 MON3 : 641 |

500N LAE 20N x 8, 1N x 16 |

| ETS-VIII | 2006 | GEO | MMH : 1120 MON3 : 1849 |

500N LAE 22N x 12 |

| SELENE | 2007 | Lunar orbit | N2H4 : 960 MON3 : 355 |

500N LAE 20N x 12, 1N x 8 |

| WINDS | 2007 | GEO | N2H4: 1460 MON3 : 1067 |

500N LAE 20N x 8, 4N x 16 |

| HTV | 2009~2020 | ISS orbit | MMH : 918 MON3 : 1514 |

500N main engine x 4 120N x 28 |

| HTV-X | 2025- (TBD) |

ISS orbit | MMH : 981 MON3 : 1619 |

120N x 24 |

| MMX (outbound) |

2026 (TBD) |

Martian moon | N2H4: 916 MON3 : 858 |

450N x 4 |

| MMX (inbound) |

2026 (TBD) |

Martian moon | N2H4: 607 MON3 : 531 |

450N x 2 22N x 20 |

Monopropellant Propulsion Systems

IHI Aerospace have developed and manufactured hydrazine propulsion systems since 1960s. We have continued to deliver a number of monopropellant systems for over 50 years A wide range of propellant tanks and thrusters developed by IA IHI Aerospace have been used on monopropellant propulsion systems.

| Program | Launch Year |

Propellant Load [kg] |

Thruster |

|---|---|---|---|

| ETS-IV | 1981 | 64 | 18N x 2 |

| ETS-III | 1982 | 18 | 1N x 12 |

| MOS-1 | 1987 | 18 | 1N x 14 |

| ETS-V | 1987 | 113 | 20N x 2 1N x 16 |

| CS-3 series |

1988 | 118 | 20N x 4 |

| MOS-1b | 1990 | 14 | 1N x 14 |

| JERS-1 | 1992 | 115 | 1N x 22 |

| ETS-VI | 1994 | 115 | 1N x 16 |

| ADEOS series |

1996- | 170 | 20N x 4 1N x 16 |

| ETS-VII | 1997 | 440 | 20N x 28 1N x 12 |

| Program | Launch Year |

Propellant Load [kg] |

Thruster |

|---|---|---|---|

| MDS-1 | 2002 | 24 | 1N x 4 |

| OICETS | 2005 | 40 | 1N x 8 |

| ALOS | 2006 | 170 | 4N x 4 1N x 16 |

| GOSAT | 2008 | 115 | 20N x 4 1N x 8 |

| GCOM series |

2012- | 260 | 4N x 12 |

| ASNARO series |

2014- | 40 | 4N x 4 |

| Government program |

2024- | - | 4N x 8 |

Launch vehicle RCS

IHI Aerospace has developed reaction control systems (RCS) for launch vehicles for over 50 years. The RCS has been used on board H-I, H-II, H-2A and H-III rockets launch vehicles which were used as Japanese flagship launchers.

| Program | Launch Year |

Thruster Configuration |

|---|---|---|

| N-I | 1975-1982 | 18N x 12 |

| N-II | 1981-1987 | 18N x 12 |

| H-I | 1986-1992 | 18N x 12 |

| H-II | 1994-1999 | 50N x8 18N x 2 |

| H-IIA | 2001- | 50N x 8 |

| H-IIB | 2009-2020 | 50N x 8 |

| Epsilon (Post Boost Stage) |

2013- | 50N x 8 |

| H3 | 2023- | 50N x 8 |

| KAIROS (Payload Acceraration Module) |

2024- | 20N x 8 |

Cold gas

We have developed and manufactured cold gas propulsion systems for small satellites with lower ΔV and sounding rockets. The simplified system reduces costs related to handling, propellant loading and transportation. We have also developed a cold gas system with liquefied gas as propellant that reduces tank volume.

| Program | Launch Year |

Propellant | Thruster Configuration |

|---|---|---|---|

| HYFLEX | 1996 | GN2 | 40N x 6 |

| ETS-Vll | 1997 | GN2 | 20N x 28 1N x 12 |

| DASH | 2002 | GN2 | 1N x 1 |

| IKAROS | 2010 | HFC-134a | 1N x 8 |

| SS-520 series | 1998- | GN2 | 23N x 1-4 |

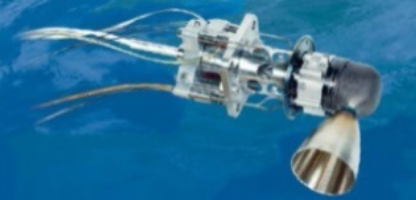

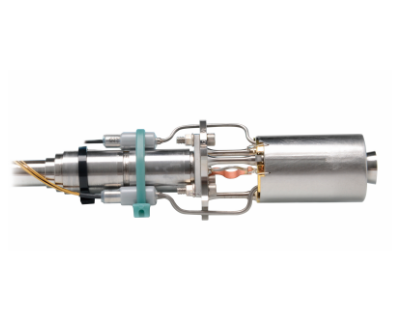

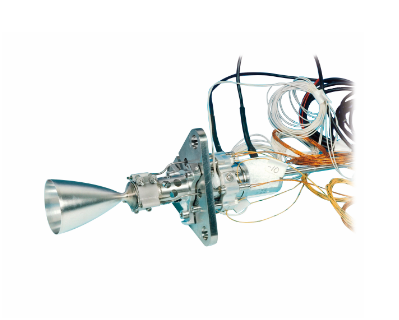

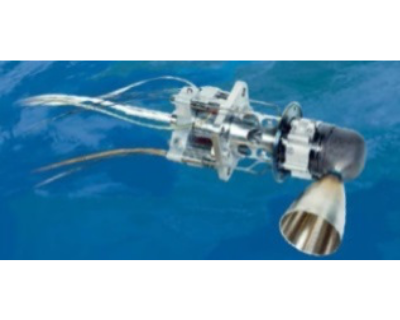

Bipropellant Thrusters

IHI Aerospace has manufactured and delivered over 400 bipropellant thrusters for spacecraft since the start of development in the 1980s. We have developed 450N thrusters and 22N thrusters with hydrazine and MON3 for geostationary satellites in 2001. The high-performance 450N thruster has been widely used by US satellite manufactures. IHI Aerospace delivered its first bipropellant thruster ,for the 1700N N2H4/MON apogee engine, in the 1980s and remains at the forefront of apogee engine production. The 490N and 120N thrusters were developed with MMH and MON as fuel for the HTV. These bipropellant thrusters are stable over a wide operational range and are reasonable price.

| Model | Propellant | Thrust | Isp | Inlet pressure | Demonstrated life | Throughput | Status |

|---|---|---|---|---|---|---|---|

| BT-4 | Hydrazine/ NTO | 450N | 326s | F : >1.69MPa O : >1.62Mpa |

32850s | - | Flight proven |

| BT-6 | Hydrazine/ NTO | 21.5N | 295s | 1.69MPa | - | 583kg | Flight proven |

| HBT-5 | MMH/MON3 | 478N | 316s | 1.72MPa | 15000s | - | Flight proven |

| HBT-1 | MMH/MON3 | 124.4N | 274.9s | 2.05MPa | 40000s | 446kg | Flight proven |

Hydrazine Bipropellant Thrusters

450N Thruster (BT-4)

450N Thruster (BT-4)

22N Thruster (BT-6)

22N Thruster (BT-6)

MMH Bipropellant Thrusters

490N Thruster (HBT-5)

490N Thruster (HBT-5)

120N Thruster (HBT-1)

120N Thruster (HBT-1)

Monopropellant Thrusters

Over 1,100 hydrazine monopropellant thrusters manufactured by IHI Aerospace have been launched since the start of development in the 1960s. Its thrust range from 1N from 50N.

| Model | Thrust | Isp | Number of pulses | Throughput | Status |

|---|---|---|---|---|---|

| MT-9 | 0.29-1.13N | 208-215s | >850,000 | >100kg | Flight proven |

| MT-8A | 1.80-5.01N | 212-225s | >850,000 | >190kg | Flight proven |

| MT-2 | 6.9-19.6N | 210-226s | >261,914 | >115kg | Flight proven |

| MT-2B | 24.5N | >211s | >7500 | >15kg | Qualified |

| MT-6 | 23-50N | 215-225s | >14,800 | >120kg | Flight proven |

| MT-6A | 50N | 225s | >14,000 | >107kg | Flight proven |

1N Thruster (MT-9)

1N Thruster (MT-9)

4N Thruster (MT-8A)

4N Thruster (MT-8A)

20N Thruster (MT-2)

20N Thruster (MT-2)

50N Thruster (MT-6)

50N Thruster (MT-6)

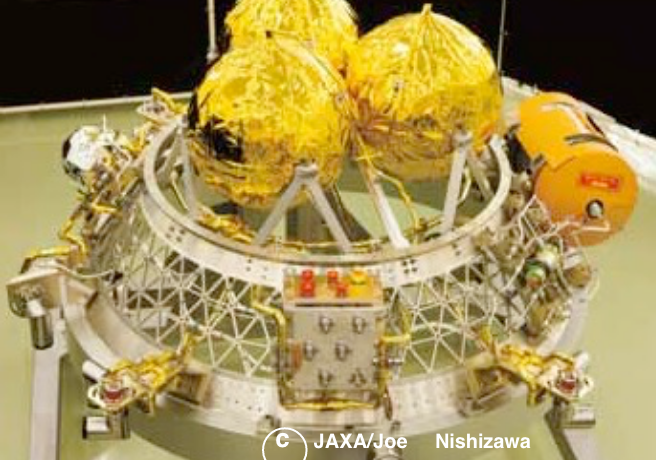

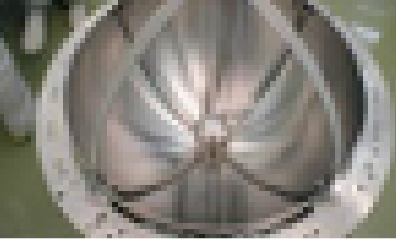

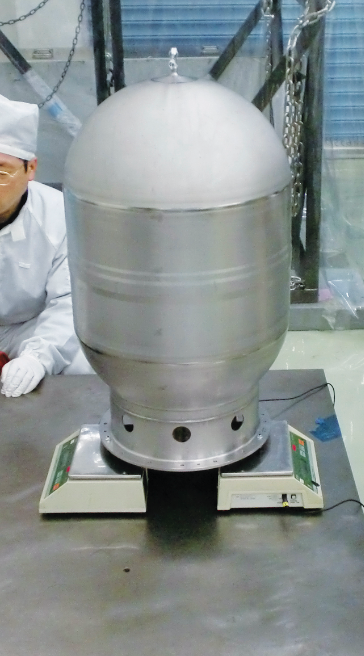

Propellant Tanks

IHI Aerospace has developed a wide range of propellant tanks and pressurant tanks for launchers and satellites since the start of development in the 1964. Over 200 propellant tanks have been launched and successfully operated. IHI Aerospace’s product line covers a wide range of tanks from 3 to 726 liters in volume and from diaphragms to surface tension channel mesh propellant management devices (PMDs).

| Volume [L] | Size [mm] | Internal device | Mount type | Status |

|---|---|---|---|---|

| 3 | 182 ID Sphere | DIAPHRAGM | Boss | Flight proven |

| 37 | 420 ID Sphere | DIAPHRAGM | 3 Tabs (Lugs) | Flight proven |

| 37 | 420 ID Sphere | DIAPHRAGM | Pedestal | Flight proven |

| 67 | 420 ID x 750 length | DIAPHRAGM | Pedestal | Flight proven |

| 74 | 420 ID x 754 length | DIAPHRAGM | 4 Tabs (Lugs) | Flight proven |

| 74 | 570 ID x 500 length | DIAPHRAGM | 4 Tabs (Lugs) | Qualified |

| 141 | 650 ID Sphere | DIAPHRAGM | 3 Tabs (Lugs) | Flight proven |

| 169 | 650 ID x 750 length | DIAPHRAGM | 3 Tabs (Lugs) | Qualified |

| 427 | 820 ID x 1087 length | CHANNEL MESH | 4Tabs (Lugs) | Flight proven |

| 552 | 1020 ID Sphere | CHANNEL MESH | 4Tabs (Lugs) | Flight proven |

| 726 | 1020 ID x 1316 length | CHANNEL MESH | 4 Tabs (Lugs) | Qualified |

Diaphragm

Diaphragm

Channel Mesh

Channel Mesh

HTV 552 [liters]

HTV 552 [liters]

ASNARO 67 [liters]

ASNARO 67 [liters]

Internal Devices

-Diaphragm (SiO2-free diaphragm is under development)

-Surface tension channel mesh

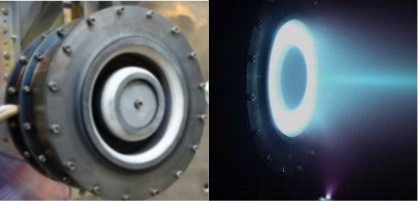

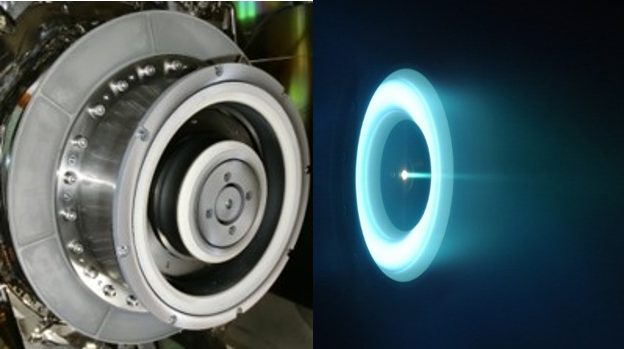

Electric Propulsion Thrusters

Electric Propulsion Thrusters

IHI Aerospace has designed, developed and manufactured several types of electric thrusters for spacecraft since 1983. We are currently developing high-power Hall Thrusters for all-electric satellites.

| Model | Propellant | Electrical Power | Thrust Level | lsp | Status |

|---|---|---|---|---|---|

| High power Hall Thruster |

Xe | 6kW | >359mN@BOL | >1783s@BOL | Qualified |

| >330mN@MOL | >1712s@MOL | ||||

| 4kW | >230mN@BOL | >1673s@BOL | |||

| >219mN@MOL | >1589s@MOL | ||||

| >212mN@EOL | >1539s@EOL |

Launch Site Support / Testing Capabilities

Launch Site Support

IHI Aerospace has a great deal of expertise and heritage in propellant loading and testing support after delivery .

Manufacturing and Testing Capabilities

Our manufacturing capabilities include the processes, testing and equipment required for fabrication of variety of propulsion components and propulsion systems for spacecraft.

- Firing test stand for apogee engines

- Firing test stand for small thrusters(3 Vacuum chambers)

- Stage firing test stand (sea level)

Contact

Click on a button below to open your mail.