MF-Detector (Metal Fragment Detector)

|

1. | MF-Detector is a high-sensitivity sensor to detect conductive particles such as copper, aluminum, and white metal in luquid oil. | |

| 2. | MF-Detector can detect damage of bearing parts etc. | ||

| 3. | The combination of MF-Detector and TF-Detector (Trace of Ferrous powder Detector) provides total damage prevention by monitoring the lubricating oil. | ||

| MF-Detector Main Unit |

Adaptable equipment and Example of conductive particles

| ・ | Condition monitoring of bearings |  |

| ・ | Condition monitoring of lubricating oil pump | |

| ・ | Condition monitoring of reduction gearbox | |

| * | (It is more effective to use MF-Detector with TF-Detector.) | |

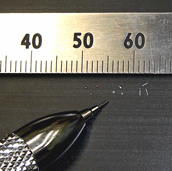

| Examples of detectable conductive particles |

Features of MF-Detector

| Detection specialized for conductive particles MF-Detector detects conductive particles such as copper, aluminum, and white metal, and moreover a small amount of air bubbles in liquid is not reacted. |

|

| Wide measuring range It can detect conductive particles from the size of 0.4 mm. (Detectable size varies depending on the material and the shape of particles.) |

|

| Sensitivity Its sensitivity is in proportion with the conductivity of the particles. |

|

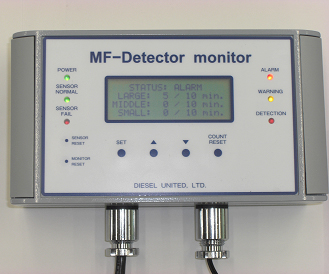

| Three size classified The detected particles are classified and counted in three (3) size (Large, Middle and Small). |

|

| Alarm contact signal Alarm contact signal is given in case particle counts exceed preset limits. Preset limits and monitoring period can be set by the monitor. |

|

| *(Power supply: 15 to 24VDC ) |

|

|

|

| MF-Detector Monitor |

*The basic system of MF-Detector consists of the main unit and the monitor. The monitor with data

logging function is available as an option.