TF-Detector (Trace-of-Ferrous-Material Detector)

|

|

Take lab-level analysis to the field. The newly developed continuous micrometer size iron powder content sensor dramatically increases the reliability and availability of equipment.

|

|

Features

✧High Resolution : It is capable of continuous measurement with high lab-level accuracy. |

✧High Applicability : It is even capable of measuring fluids with temperature, pressure, and viscosity changes. |

✧High Adaptability : With a built-in pump(only TF-Detector R), it is compatible with any equipment and can be installed anywhere. |

✧Highly Robust : It operates stably even in harsh environments (e.g. vibration and temperature). |

✧Remote Monitoring : Remote monitoring is possible in real time so as not to miss any status changes. |

Solution

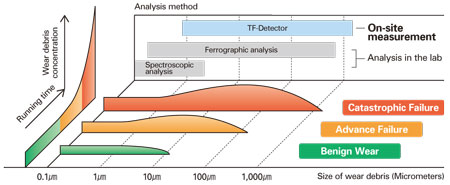

Equipment with wear deteriorates rapidly when the wear limit is exceeded, leading to damage within a short period. This is why high-frequency and high-precision wear debris analysis has to be performed to assess the wear limit. With lab-level accuracy and continual quantitative monitoring of the wear status compared to normal wear, the TF-Detector is the ideal solution to prevent equipment damage and ensure safe and planned operational management |

||

|

||

Applications

The TF-Detector can be used in a wide range of fields including energy, marine, petrochemical and other industries.

| Energy | Marine | Petrochemicals | Industrial Machinery | |||

|

|

|

|

|||

Wind turbine generators, Gas turbine generators, Reciprocating engine generators |

Propeller shafts, Gearboxes, Propulsion and power generation engines |

Large compressors, Large pumps, Large agitators |

Iron and papermaking equipment, Large hydraulic equipment, Large blowers, Crushers |

Products

TF-Detector R New Release! |

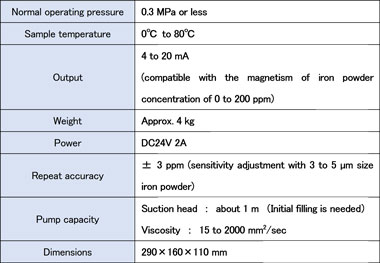

Specification |

|

Built-in pump enables continuous measurement of sample circulation.  |

| On-line Flange type | On-line Passage type | Portable type |

|

|

|

It can be applied to samples that contain a large amount of sludge. (It can also be applied to ordinary lubricating oil.) |

Suitable for monitoring abnormal wear of rolling bearings and gears. |

The measurement result can be saved in the main memory together with the date and time. It is also possible to take out the data in the memory with an memory card and organize it on a PC. |