Products

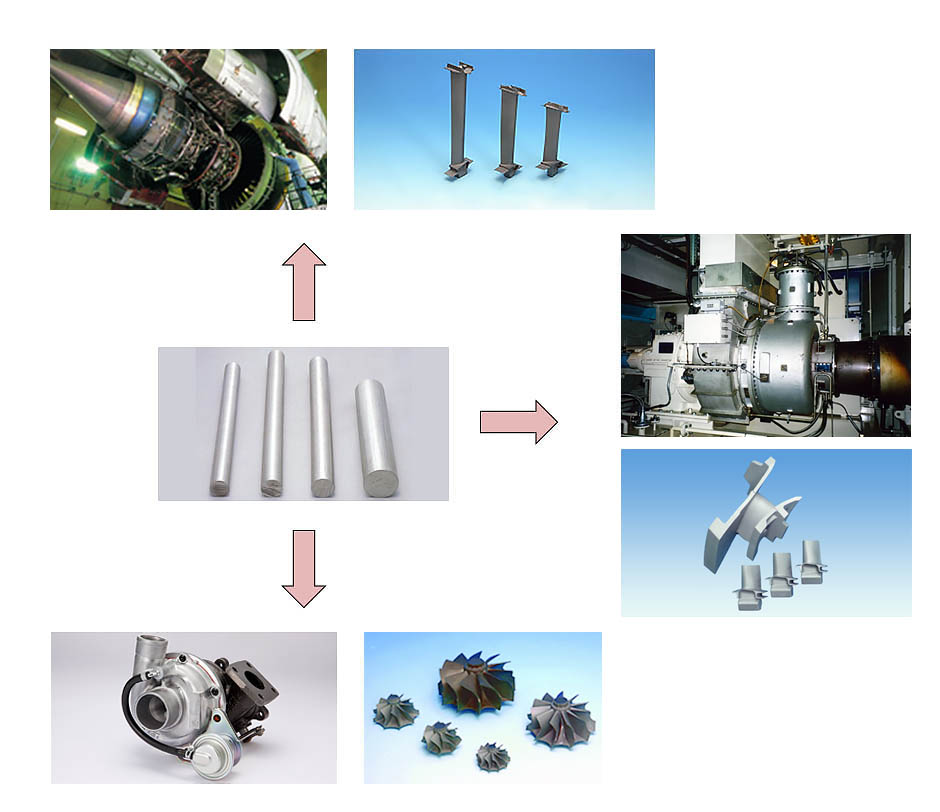

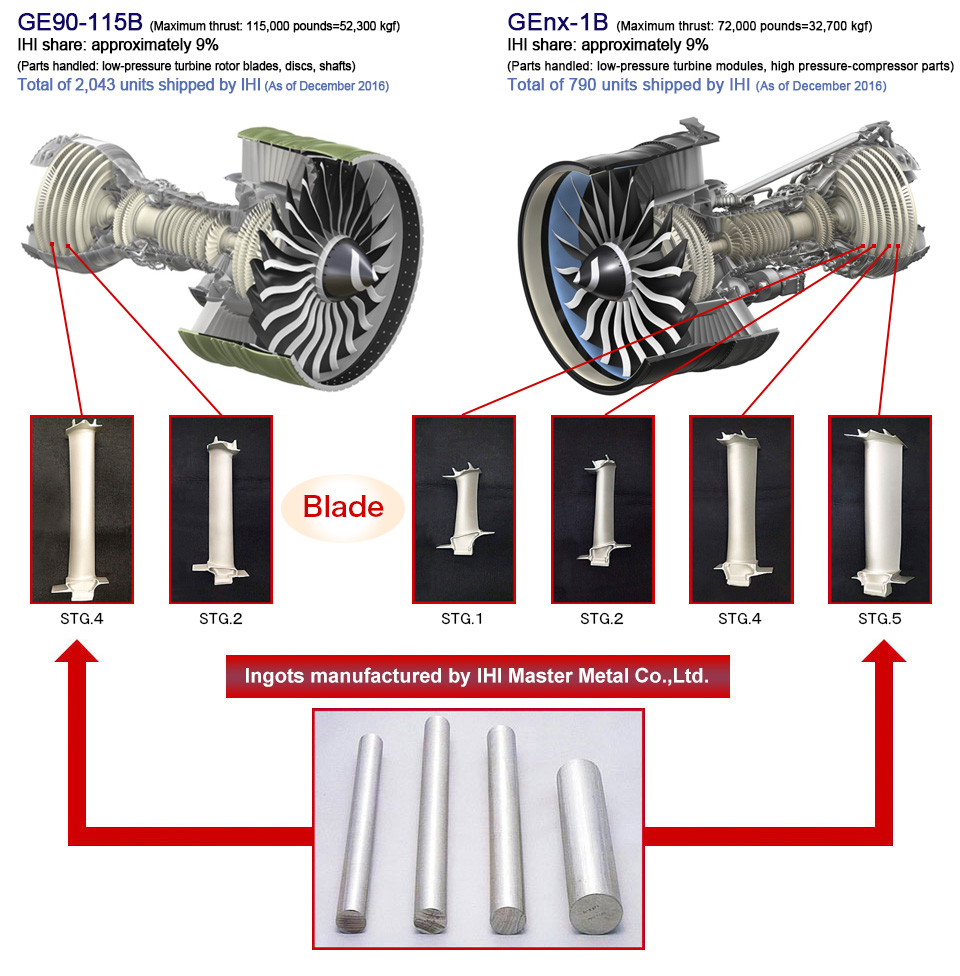

- IHI Master Metal mainly produces superalloy ingots for cast turbine blades used in aviation engines, industrial gas turbines and vehicle superchargers.

- We apply the vacuum melting technology expertise we have accumulated over more than 30 years to manufacture nickel- and cobalt-based superalloys and deliver them in a timely manner to customers in Europe, the US, and Asia, as well as domestically. We have earned our customers' trust and a reputation for quality.

- As part of the IHI Group, we will continually strive to maintain and improve our position as a top manufacturer of ingots for vacuum casting.

Products handled

- Nickel-based alloy ingots for precision casting

- Cobalt-based alloy ingots for precision casting

Master ingot products

Master ingot products (N & B)

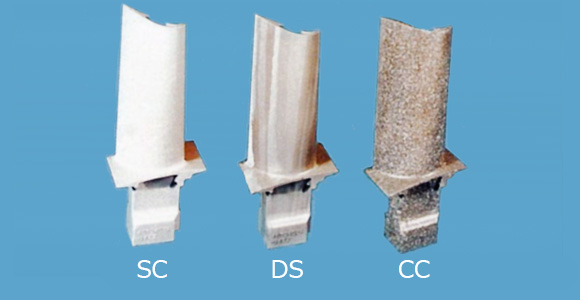

Types of nickel-based alloy ingots for precision casting

- For single crystal casting

(SC: Single Crystal) - For directional solidification casting

(DS: Directional Solidification) - For conventional casting (equiaxed crystal)

(CC: Conventional (Equiax) Casting)

Example of customer's application (turbine blade)

Certifiactions/Accreditations

~Public institution Certifiactions/Accreditations~

- JISQ9100 = AS9100, EN9100

Quality Management System - Requirements for aerospace and defense organizations - JISQ140001 = ISO14001

Environmental Management System - Requirements and User guide - JISQ17025 = ISO/IEC 17025

General requirements for capabilities of laboratoriesan and calibration

organizations : Chemical Analysis - Nadcap

Material Testing Laboratories (Chemical Analysis)

~Customer's Certifiactions/Accreditations~

- Pratt&Whitney

Chemical Analysis commercial Lab certification - Ni, Co, Fe-alloy - GE Aviation

P1TF37 Code GA (Melting Process) , S-400 Code GA, AI (Chemical Anaysis) - Rolls-Royce Ltd.

MLC101(Material manufacturing), MSRR9920(Chemical Analysis) - IHI

ISAJT-F005(Chemical Analysis)