Immersion type

Features

- Safety

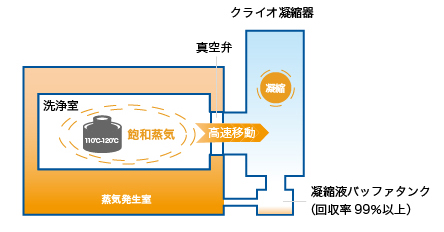

- All process for degreasing is under vacuum and with no danger of firing and explosion.

- Energy-saving

- Low temperature treatment all below 120 ℃.

- High Quality

- All soiled solvent is collected and regenerated in the distiller under a reduced pressure.

Any gathered grease is to be condensed and drawn out.

Remarks:

- Actual drying time is depending on treated products.

- After installation, commissioning and instruction are necessary before hand over.

- Period for ancillary work, optional item and loading test shall be additionally considered.

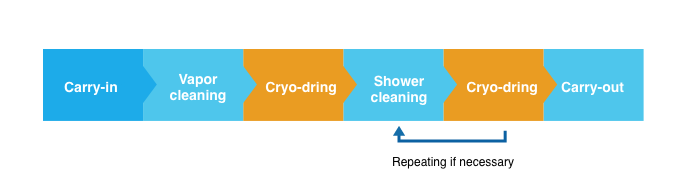

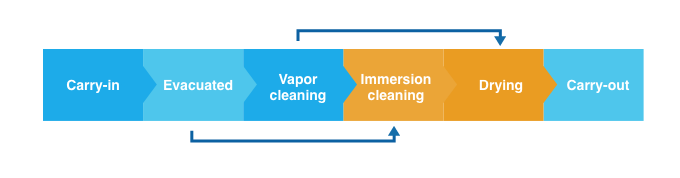

Process flow

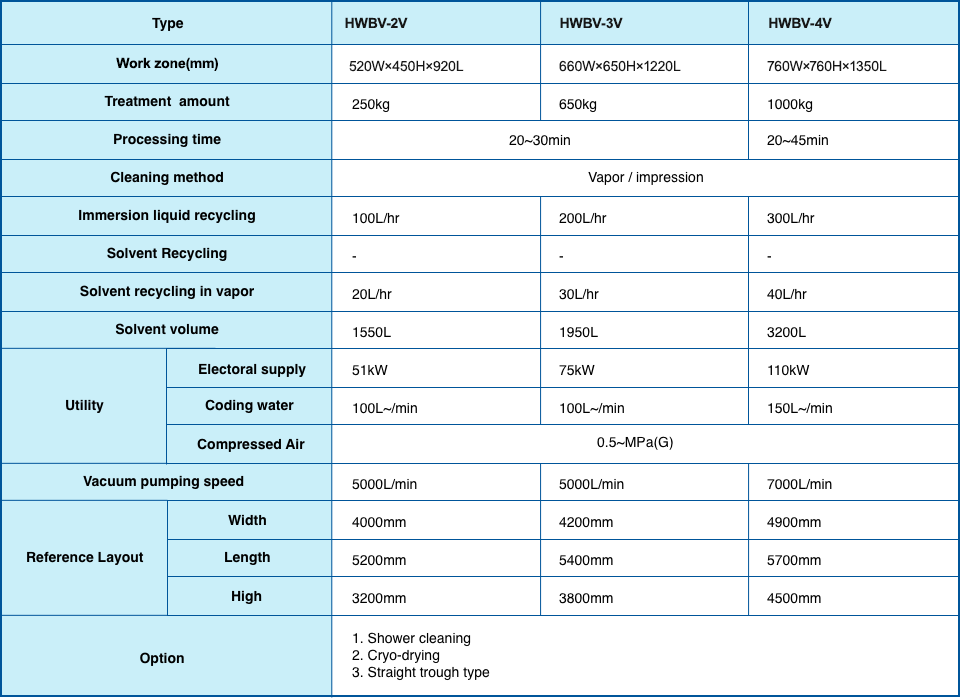

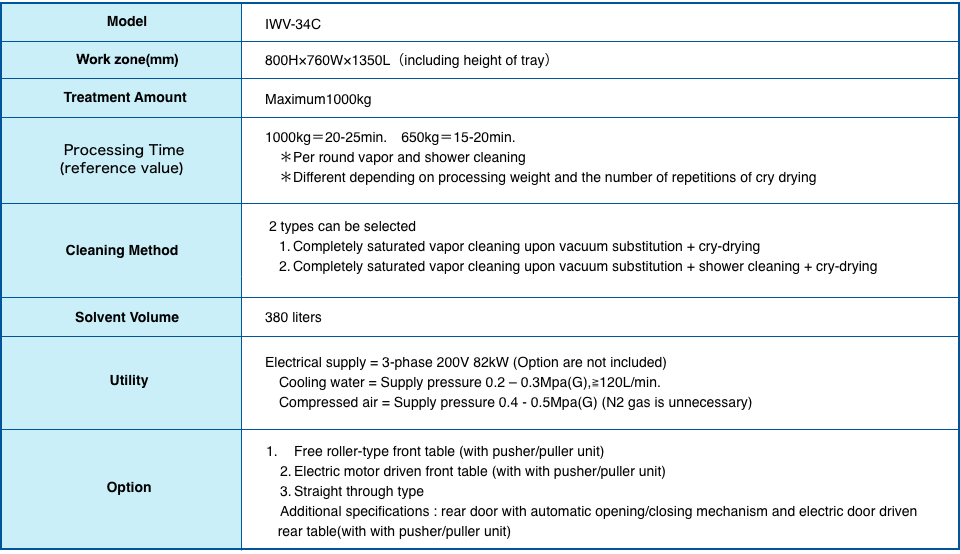

Standard specifications