SEPARATOR / DEHYDRATOR

- TOP

- SEPARATOR / DEHYDRATOR

- Guinard Centrifuge

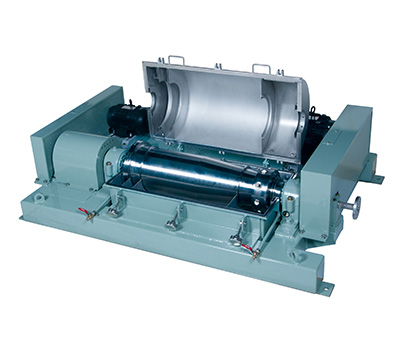

- HL2 Type

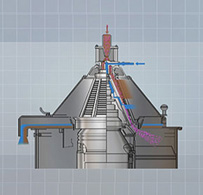

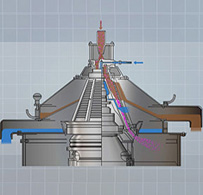

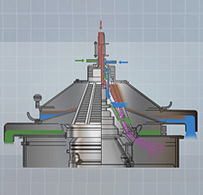

Guinard Centrifuge

HL2 Type

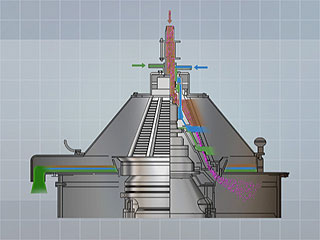

2-stage washing type

Designed for 2-stage washing to enhance washing effectiveness or when using two types of washing liquids in the washing process

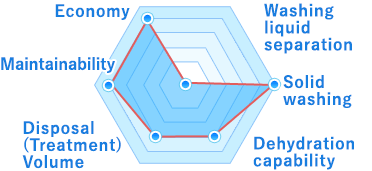

- Economy

- 4

- Maintainability

- 4

- Disposal (Treatment) Volume

- 3

- Dehydration capability

- 3

- Solid washing

- 5

- Washing liquid separation

- 0

- Total

- 19

Features

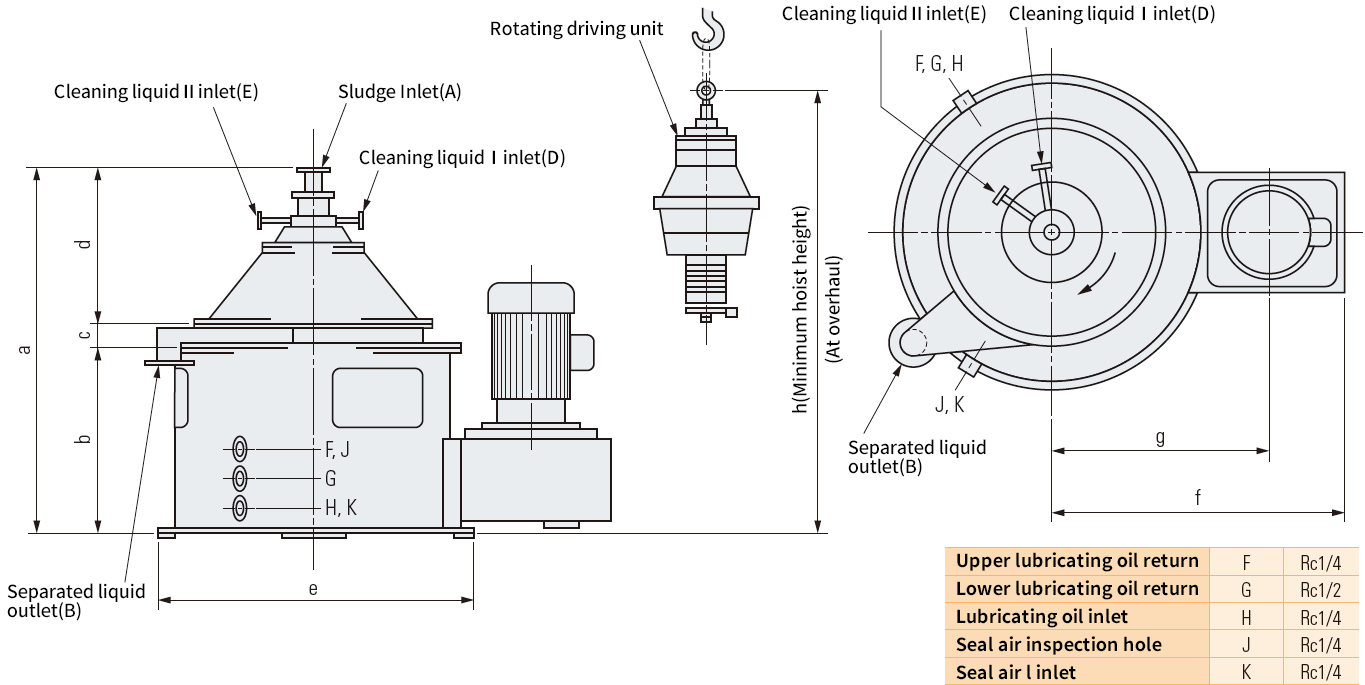

Dimensions

| Type | Key Dimensions (mm) |

||||||||

|---|---|---|---|---|---|---|---|---|---|

| a | b | c | d | e | f | g | h | ||

| C20 | H | 928 | 485 | 99 | 344 | 725 | 790 | 570 | 1300 |

| HL | 946 | 485 | 99 | 362 | 725 | 790 | 570 | 1300 | |

| HLS | 946 | 485 | 159 | 302 | 725 | 790 | 570 | 1300 | |

| C30 | H | 1153 | 600 | 75 | 478 | 1000 | 1000 | 735 | 1600 |

| HL | 1181 | 600 | 75 | 506 | 1000 | 1000 | 735 | 1600 | |

| HLS | 1181 | 600 | 153 | 428 | 1000 | 1000 | 735 | 1600 | |

| HL2 | 1213 | 600 | 75 | 538 | 1000 | 1000 | 735 | 1600 | |

| HL2S | 1213 | 600 | 153 | 460 | 1000 | 1000 | 735 | 1600 | |

| C40 | H | 1383 | 680 | 116 | 587 | 1350 | 1325 | 1000 | 1900 |

| HL | 1411 | 680 | 116 | 615 | 1350 | 1325 | 1000 | 1900 | |

| HLS | 1411 | 680 | 228 | 503 | 1350 | 1325 | 1000 | 1900 | |

| HL2 | 1443 | 680 | 116 | 647 | 1350 | 1325 | 1000 | 1900 | |

| HL2S | 1443 | 680 | 228 | 535 | 1350 | 1325 | 1000 | 1900 | |

| C55 | H | 1835 | 800 | 147 | 888 | 1568 | 1548 | 1200 | 2300 |

| HL | 1835 | 800 | 147 | 888 | 1568 | 1548 | 1200 | 2300 | |

| HLS | 1835 | 800 | 273 | 762 | 1568 | 1548 | 1200 | 2300 | |

| HL2 | 1887 | 800 | 147 | 940 | 1568 | 1548 | 1200 | 2300 | |

| HL2S | 1887 | 800 | 273 | 814 | 1568 | 1548 | 1200 | 2300 | |

| Type | Slurry input |

Separated liquid Output |

Washing fluid Output |

Washing fluid1 Inlet |

Washing fluid2 Inlet |

|

|---|---|---|---|---|---|---|

| A | B | C | D | E | ||

| C20 | H | 25A | 50A | — | — | — |

| HL | 25A | 50A | — | 15A | — | |

| HLS | 25A | 50A | 50A | 15A | — | |

| C30 | H | 40A | 65A | — | — | — |

| HL | 40A | 65A | — | 15A | — | |

| HLS | 40A | 65A | 65A | 15A | — | |

| HL2 | 25A | 65A | — | 15A | 15A | |

| HL2S | 25A | 65A | 65A | 15A | 15A | |

| C40 | H | 40A | 80A | — | — | — |

| HL | 40A | 80A | — | 15A | — | |

| HLS | 40A | 80A | 80A | 15A | — | |

| HL2 | 40A | 80A | — | 15A | 15A | |

| HL2S | 40A | 80A | 80A | 15A | 15A | |

| C55 | H | 65A | 200A | — | — | — |

| HL | 65A | 200A | — | 15A | — | |

| HLS | 65A | 200A | 200A | 15A | — | |

| HL2 | 65A | 200A | — | 15A | 15A | |

| HL2S | 65A | 200A | 200A | 15A | 15A | |

Specifications

| Type | Primary Specifications | ||||

|---|---|---|---|---|---|

| Basket | Motor | Equipment mass |

Main drive unit |

||

| Inner diameter (mm) |

(kW) | (kg) | Weight (kg) |

||

| C20 | H | 200 | 2.2 | 190 | 40 |

| HL | 200 | 2.2 | 190 | 40 | |

| HLS | 200 | 2.2 | 190 | 40 | |

| C30 | H | 300 | 5.5 | 700 | 105 |

| HL | 300 | 5.5 | 700 | 105 | |

| HLS | 300 | 5.5 | 700 | 105 | |

| HL2 | 300 | 5.5 | 700 | 105 | |

| HL2S | 300 | 5.5 | 700 | 105 | |

| C40 | H | 400 | 15 | 1350 | 195 |

| HL | 400 | 15 | 1350 | 195 | |

| HLS | 400 | 15 | 1350 | 195 | |

| HL2 | 400 | 15 | 1350 | 195 | |

| HL2S | 400 | 15 | 1350 | 195 | |

| C55 | H | 550 | 30 | 2300 | 425 |

| HL | 550 | 30 | 2300 | 425 | |

| HLS | 550 | 30 | 2300 | 425 | |

| HL2 | 550 | 30 | 2300 | 425 | |

| HL2S | 550 | 30 | 2300 | 425 | |

| Type | Primary Specifications | ||||

|---|---|---|---|---|---|

| Designed load | Disposal(Treatment) Volume(Reference value) |

Maximum centrifugal efficiency |

Utilities (Reference value) |

||

| (kN) | Separated liquid volume (m3/hr) |

(G) | Seal air (Lit/min) |

||

| C20 | H | 5 | 1 | 1800 | 50〜100 |

| HL | 5 | 1 | 1800 | 50〜100 | |

| HLS | 5 | 1 | 1800 | 50〜100 | |

| C30 | H | 20 | 3 | 1800 | 100〜200 |

| HL | 20 | 3 | 1800 | 100〜200 | |

| HLS | 20 | 3 | 1800 | 100〜200 | |

| HL2 | 20 | 3 | 1800 | 100〜200 | |

| HL2S | 20 | 3 | 1800 | 100〜200 | |

| C40 | H | 35 | 5.5 | 1800 | 100〜300 |

| HL | 35 | 5.5 | 1800 | 100〜300 | |

| HLS | 35 | 5.5 | 1800 | 100〜300 | |

| HL2 | 35 | 5.5 | 1800 | 100〜300 | |

| HL2S | 35 | 5.5 | 1800 | 100〜300 | |

| C55 | H | 60 | 11 | 1500 | 200〜500 |

| HL | 60 | 11 | 1500 | 200〜500 | |

| HLS | 60 | 11 | 1500 | 200〜500 | |

| HL2 | 60 | 11 | 1500 | 200〜500 | |

| HL2S | 60 | 11 | 1500 | 200〜500 | |

- Note 1: The treatment capacity of this machine is primarily determined by the separated liquid volume. The separated liquid volume, including washing liquids, may vary depending on the properties of the treated material. Please use the values as a reference for selecting a model.

- Note 2: The centrifugal efficiency (500G - 1800G) and the treatment capacity are determined by test results or actual performance.

-

Note 3: Seal air is required to reduce the negative pressure inside the rotating bowl.

Shown are the reference values (at Normal) and these values may vary slightly depending on the pressure balance before and after separation. - Note 4: Standard material is SUS304. Depending on the properties of the treatment material, we also manufacture this machine in other materials, such as SUS316, SUS316L, Hastelloy, and titanium.

-

Note 5: Understanding the model type codes (e.g. C40HLS)

C40: Indicates model type and size. The number indicates the inner diameter of the basket base in centimeters.

HL: Indicates variation. In this case, HL indicates tall basket/1-stage washing.

S: Also indicates variation. S indicates it is a washing liquid separation type.

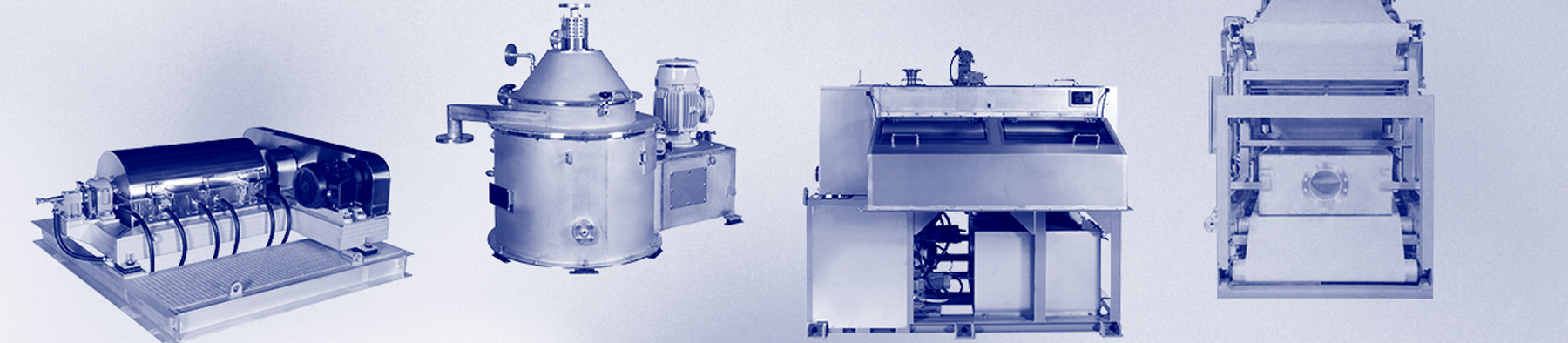

Select another product

-

H type

-

HL type

-

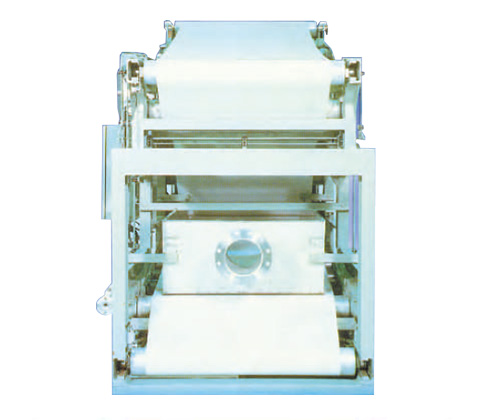

HLS Type

-

HL2S Type

washing liquid separation type Designed for 2-stage washing to enhance washing effectiveness or when using two types of washing liquids in the washing process. Used for separating and recovering the separated liquid, washing liquid I, and washing liquid II.

About the evaluation criteria

About the evaluation criteria