Development of the world’s first air-cooling system for aircraft onboard 100kW-class power electronics - The “liquid-less”, clean cooling technology enlarges applicability of the power electronics -

IHI Corporation (Headquarter: Tokyo, Japan, CEO: Tsugio Mitsuoka, hereinafter referred to as “IHI”) leads More Electric Architecture for Aircraft and Propulsion (hereinafter referred to as “MEAAP”) that aims at the optimization of the total energy management of aircraft system with technological innovation toward CO2 emission reduction from aviation. One of the key MEAAP concepts is the air-cooling system for the onboard power electronics. The liquid-less cooling technology increases flexibility of the power electronics application, even if it’s a location where coolant, water and oil can’t be used. IHI developed the air-cooling system for the aircraft onboard 100kW-class high power electronics, and successfully completed the evaluation testing.

This development was conducted as one of Research and Development Project for Advanced Aircraft Systems toward Practical Application supported by New Energy and Industrial Technology Development Organization (Director: Hiroaki Ishizuka, hereinafter referred to as “NEDO”).

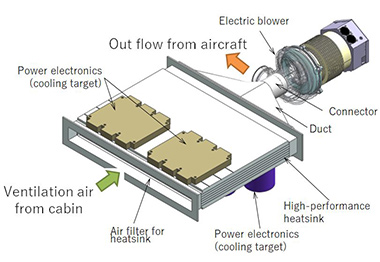

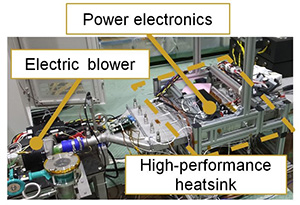

| Fig.1 The air-cooling system for the onboard power electronics | Fig.2 The evaluation testing for the 100kW-class power electronics |

[Background of the development]

The world-wide environmental consideration has led technological innovation and adaptation of the electrification, especially for the automobile application. The aviation industry, too, is pursing the electrification technology and introduces it into the aircraft. For the aircraft system, flight safety is the first priority, and environmental adaptation and economical rationality should be also satisfied. So the MEAAP focuses on not only the component electrification, but also the total system optimization considering the system safety, efficiency, and volume & weight reduction.

While the aircraft system electrification improves the fuel consumption, heat generation from the power electronics causes serious thermal management issue, because large amount of heat should be dissipated within the aircraft system. Today’s onboard high power electronics usually adapts the liquid-cooling system which consists of coolant pumps, tanks, heat exchangers and ducts & tubes, and there is certain constraint of its location and installation. In addition the typical coolant liquid requires careful attention to treat during the maintenance. The air-cooling system is an environmental and human-friendly system, and allows flexible arrangement of the power electronics.

[Developed Technology]

High power density, compact and light weight are the distinctive feature of the power electronics for aircraft onboard application, i.e. the heat generation is localized in the small area and in general air-cooling is not suitable for such condition. IHI developed the highly efficient cooling system using air to remove the localized heat from the onboard power electronics. Moreover the system uses aircraft ventilation air, which is always exhausted from aircraft cabin to keep outside fresh air coming in. By the combination with the cabin air management system, the cooling system can save its consumed energy.

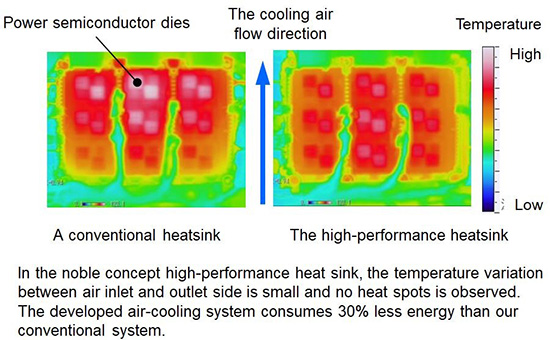

IHI employed expertise of the thermal, fluid and structural analysis technology, and developed a noble concept heat sink, which reveals both higher heat dissipation density and lower pressure loss than current air-cooling heat sink. A compact electric motor-driven blower, which is a high rotational speed and oil-free machine adapting own air-cooling technology, is also developed utilizing our vehicular turbo charger technology. IHI constructed the air-cooling system with combination of the heat sink and electric blower, and the cooling capability testing was conducted at IHI Yokohama facility in February, 2020. We confirmed the cooling performance for the onboard 100kW-class high power electronics.

| Fig.3 The temperature measurement data of the power electronics devices with the noble concept high-performance heat sink |

[Future plan]

IHI is studying innovative technology and optimization of energy management for the future electrified aircraft aiming at introduction of the MEAAP concept in 2030s.

IHI’s air-cooling system will be one of the solutions for the power electronics cooling, not only for the aircraft but also other industrial application, particularly in which coolant liquid can’t be used. IHI is pursuing the power electronics system approach applying our clean, compact and efficient air management technology, to any industrial field including mobility.

[Reference Information]

Press Release announced on March 30, 2020

“Development of the world’s first Aircraft jet engine-embedded electric machine with high power density and heat resistant ~For optimizing the energy management of aircraft system to reduce CO2 emission~”

https://www.ihi.co.jp/en/all_news/2019/aeroengine_space_defense/1191910_2025.html