IHI and Idemitsu to Jointly Explore Establishing Ammonia Supply Chain

IHI Corporation and Idemitsu Kosan Co.,Ltd. announced today that they have concluded an agreement to jointly explore establishing an ammonia supply chain at the latter’s Tokuyama Complex in Yamaguchi Prefecture. They will also consider ammonia co-firing at a naphtha cracking furnace.

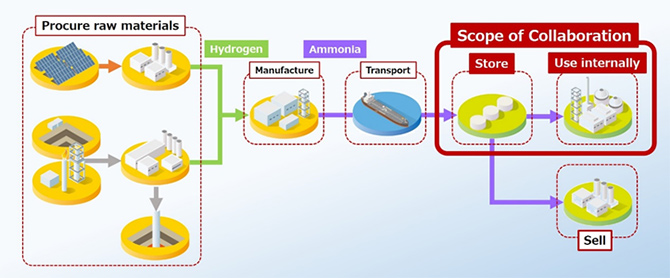

Ammonia supply chain and scope of collaboration

Both companies have collaborated to date at that complex, notably for storage facilities. Based on the agreement, the two will use Idemitsu’s storage, petrochemicals equipment, and other existing facilities at the Tokuyama Complex to repurpose it as an ammonia import terminal. Idemitsu will conduct an ammonia supply chain demonstration and obtain domestic permits and approvals with a view to supplying ammonia to nearby business sites at the complex. IHI will leverage its ammonia storage and combustion technologies to evaluate ammonia storage and receipt and shipment facilities and assess trial ammonia combustion. Idemitsu also considers importing blue ammonia, the fruit of a production process that captures and stores carbon dioxide emissions, and green ammonia, which uses renewable energy, as well as supplying ammonia to the complex and other facilities nearby.

The Japanese government’s commitment to make the nation carbon-neutral by 2050 prompted public and private sector entities to collaborate, such as in striving to materialize a hydrogen carrier chain that employs hydrogen and ammonia. Initiatives have already begun in Japan and elsewhere to look into manufacturing blue and green ammonia. Developing facilities to establish a commercial-scale supply chain that encompasses import terminals and other facilities has necessitated medium- to long-term horizons and swifter, more efficient technology demonstration projects.

Idemitsu has looked into setting up a hydrogen and ammonia supply chain. Its efforts in that regard have included having representatives of the Tokuyama Complex Plant and Group refineries participate in the Ministry of Land, Infrastructure, Transport and Tourism’s Study Committee for Carbon Neutral Port. The company has additionally mulled collaborating with other companies to procure blue and green ammonia from abroad.

Idemitsu has streamlined its operations over the past decade by harnessing infrastructure formerly used in petroleum refining. In 2014, for example, the company shut down the crude oil refinery at the Tokuyama Complex, making it one of the first petrochemical feedstock manufacturing sites to transition away from petroleum refining. In January this year, the site inaugurated a high-efficiency naphtha cracking furnace that consumes around 30% less energy than conventional setups. Idemitsu is accelerating a drive to decarbonize its operations by constructing a biomass power plant that should come online in 2022.

IHI embarked on developing ammonia combustion technology in 2014. It is a world leader in innovating techniques to co-fire ammonia with coal or natural gas to fuel power stations. IHI became the world’s first to attain a 70% liquid ammonia co-firing ratio on a 2,000-kilowatt-class gas turbine. It plans to trial ammonia co-firing at a commercial coal-fired power station. IHI is additionally evaluating the establishment of an ammonia supply chain in Japan and overseas with a view to embedding ammonia fuel in the social infrastructure.

Idemitsu and IHI will leverage their strengths through the new agreement to help materialize a carbon-neutral economy by swiftly creating a world-class ammonia supply chain.