IHI and JFE Steel to Demonstrate Automated Transport System to Verify and Enhance Practicality of Traffic-Control Methods for Site Vehicles and Pedestrians

IHI Corporation and JFE Steel Corporation today announced that they will use a retrofitted truck to demonstrate an automated transport system at the Keihin District of the latter’s East Japan Works from February 2023.

IHI has been developing factory transport vehicle automation technologies to overcome driver shortages and enhance worksite conditions. In the fiscal year ending in March 2020, IHI and JFE Steel embarked on joint research to create a practical new system. They developed a basic automated technology for automated driving, turning, and stopping. They will test this setup with a tractor-trailer (see note 1) carrying 100 metric tons of freight over a three-kilometer route at the Keihin District.

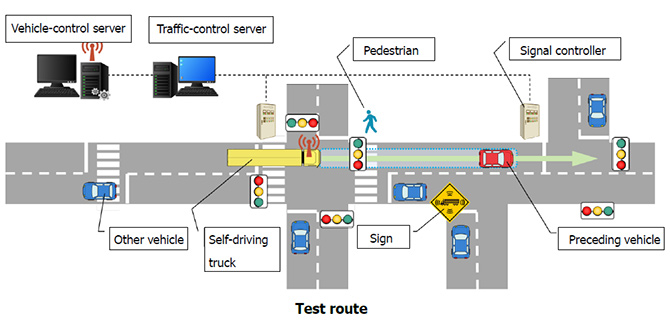

They will install signs at intersections and crosswalks along the route and control traffic lights to verify notifications to other vehicles and pedestrians when automated vehicles approach. They thereby seek to improve transportation safety and build acceptance for automated systems. In addition, we will confirm the numbers and the installation spots of sensors and cover the whole transporting route until 2023 FY. They will additionally explore specifications for the number and positioning of vehicle-mounted peripheral object detection sensors, with a view to completing testing on all sections of the route during the fiscal year ending in March 2024.

IHI and JFE Steel will deploy the new system on other routes and vehicles in the Keihin District to contribute to manufacturing process innovations. IHI aims to leverage this system and other advances to foster economic progress. It will do so by delivering customer solutions for an array of industries and transported goods by combining cargo handling machines, automated warehouses, and other labor-saving setups and system components.

System Features

- The control room radios instructions to the truck, which starts operating. A controller on the truck instructs the actuator and electronic drive-by-wire mechanism to operate the gas pedal, brake, and steering wheel based on the vehicle’s position, speed, and other information that sensors collect.

- The traffic-control server controls traffic signals and other equipment according to vehicle progress along the road. It also instructs the vehicle-control server to have the truck proceed or stop., thereby controlling traffic at intersections and pedestrian crossings to ensure that truck operations are safe and efficient.

- A global navigation satellite system (see note 2) serves as a sensor to determine the truck’s location and speed. If buildings or other structures block satellite reception, matching light detection and ranging sensor (see note 3) measurement data with pre-acquired three-dimensional map data can estimate the vehicle’s position and speed. The truck can accordingly operate automatically indoors and outdoors. IHI will select mounted sensors according to the driving environment.

Notes

- 1. A tractor-trailer combines a tractor unit and one or more semi-trailers to carry large freight loads. A semi-trailer attaches to the tractor with a hitch called a fifth wheel. Tractor-trailers can carry bigger and longer loads than single unit trucks. At the same time, tractor-trailers have complex operating requirements owing to the pivot between the tractor and the trailer.

- 2. A global navigation satellite system triangulates the current position by using signals from multiple positioning satellites to determine the distance to a satellite.

- 3. A light detection and ranging system constantly emits laser beams to objects, measuring the distance to and positions of these objects based on the reflections.

Related news release