Kobenable Steel to drive decarbonization of the Japanese construction industry

-Low CO₂ blast furnace steel employed as building material for the Toyosu area development project-

IHI Corporation

Mitsubishi Estate Co., Ltd.

Kajma Corporation

Kobe Steel, Ltd.

We announce today that IHI Corporation, Mitsubishi Estate Co., Ltd. and Kajima Corporation have decided to use Kobenable Steel, Japan’s first low CO₂ blast furnace steel product developed by Kobe Steel, Ltd., for the construction of a property tentatively called Toyosu 4-2 Development Project, Building B (Toyosu, Koto-ku, Tokyo).*1

As the world moves toward a common goal of achieving carbon neutrality, calls for decarbonization efforts are increasing in the high-rise building construction field as well. In particular, the construction industry is taking steps to reduce CO₂ emissions from building materials throughout the entire supply chain, thus spurring demand for steel frames manufactured with less CO₂ emissions for construction of buildings.

Kobenable Steel, developed by Kobe Steel's original CO₂ reduction solution for blast furnace ironmaking,*2 allows the supply of low-CO₂ steel products that maintain the same level of high quality as conventional products. The use of Kobenable Steel for part of the steel frames of the property will contribute to the reduction of CO₂ emissions from building materials. The companies plan to use Kobenable Premier, which reduces 100% of CO₂ emissions based on the mass-balance method,*3 as building material for the property.

Our four companies will promote initiatives in support of the Sustainable Development Goals (SDGs) and work to realize a decarbonized society as we perform "Responsible Consumption and Production” and contribute to “Sustainable Cities and Communities” with Kobenable Steel as the driving force.

*1 Project overview of the Toyosu 4-2 Development Project, Building B (tentative name)

Through this large-scale development project in the Tokyo Bay area, we aim to increase the value of the area by creating new attractions that will be loved by the local community.

|

|

Developers: IHI Corporation, Mitsubishi Estate Co., Ltd. |

|

|

Designer/Constructor: Kajima Corporation |

|

|

Location: 14-2, 4, and 5 Toyosu 2-Chome, Koto-ku, Tokyo |

|

|

Schedule: Construction to start in July 2022 and end in June 2025 (planned) |

|

|

Building use: Offices, incubation facilities, stores, shared company dormitories, and parking lots |

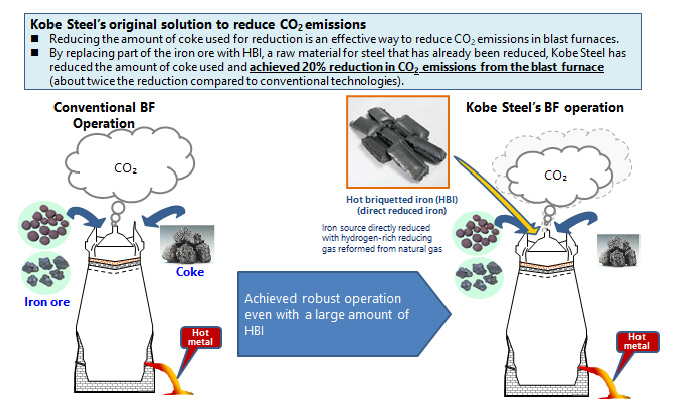

*2 Kobe Steel’s original CO₂ reduction solution for blast furnace ironmaking

This technology, demonstrated at Kobe Steel’s production site Kakogawa Works, achieves a significant reduction of CO₂ emissions from the blast furnace by charging into the blast furnace a large amount of hot briquetted iron (HBI) manufactured via the MIDREX® Process, a direct reduced ironmaking process, accounting for about 80% of the world’s natural gas-based direct reduced iron (DRI) production (60% of the world’s overall DRI). It can reduce CO₂ emissions in the blast furnace ironmaking process by 20–40%.

*3 Mass-balance method

The mass-balance method is to allocate specific characteristics to a certain portion of products according to the input amount of raw materials with the characteristics when there is a mix of raw materials with and with no such characteristics (e.g., low CO₂) in the manufacturing process.