IHI Group to Contribute Further to Carbon Dioxide Recycling from Exhaust Gases through New JFE Steel Order for World’s Largest Methanation Unit

IHI and subsidiary IHI Plant Services Corporation today announced that JFE Steel Corporation has ordered a methanation unit. The new setup will recycle 24 metric tons of carbon dioxide daily from test blast furnace gas, producing 500 normal cubic meters of methane per hour. This carbon capture and utilization unit will have what is currently the world’s largest manufacturing capacity for such a facility. The IHI Group will draw on this order in a drive to upscale methanation equipment.

The order came through the Hydrogen Utilization in Iron and Steelmaking Processes Project. That initiative of the New Energy and Industrial Technology Development Organization of Japan’s Green Innovation Fund (see note) aims to develop low-carbon and other technologies that tap external hydrogen and carbon dioxide from blast furnace exhaust gases.

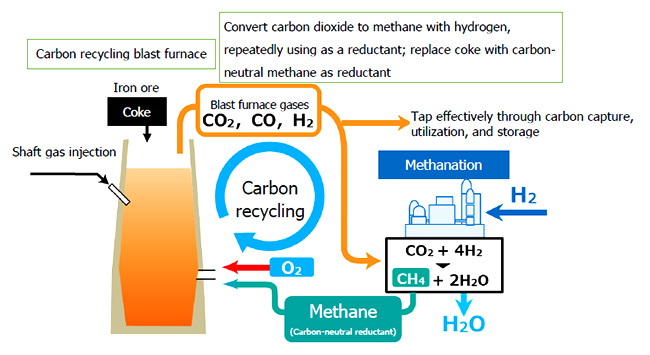

Steel sector production accounts for around 40% of Japan’s industrial carbon dioxide emissions. JFE Steel developed carbon recycling blast furnace and other technology that it is leveraging in an effort to more than halve current carbon dioxide emissions. This technology works by converting in-furnace carbon dioxide emissions to methane, repeatedly using the methane as a reduction agent to replace part of coke in furnaces.

IHI will push ahead with development that centers on upgrading catalysts, enlarging reactors, and enhancing processes to tap reaction heat effectively for the methanation unit. The company plans to deliver that unit in the fiscal year ending March 2025. It also seeks to attain commercial methanation capacity in Japan and abroad of between several thousand and tens of thousands of normal cubic meters per hour by 2030.

Methanation synthesizes methane from carbon dioxide and hydrogen. Such methane from business site carbon dioxide emissions can be an alternative to natural gas at these facilities or go into city gas pipelines for use at other sites or homes. Methanation could become a key technology for achieving carbon neutrality because it can use the existing city gas infrastructure.

IHI will help materialize carbon neutrality in 2050 by providing engineering services that combine diverse solutions. These include carbon dioxide recovery technology and a service that uses blockchain technology to record and identify carbon dioxide emissions and reductions calculated from facilities operation data, converting it into environmental value that it distributes in external markets through its environmental value management platform.

Note:

- Green Innovation Fund

NEDO decided to create a ¥2 trillion fund to ramp up current efforts to achieve carbon neutrality by 2050, including to structurally transform the energy and industrial sectors and invest extensively in innovation. The fund will provide ongoing support to public and private sector entities collaborating to pursue specific goals in everything from R&D through demonstrations and social implementation of outcomes over the next 10 years. This assistance is primarily in 14 priority fields for which the Green Growth Strategy has formulated action plans. Go to the website below for more information about the fund.

Related links

September 1, 2022 – JFE Steel Corporation Carbon Neutrality Strategy Briefing

https://www.jfe-holdings.co.jp/en/investor/climate/presentation/index.html#20220901

October 21, 2022: IHI Launches Methanation System to Produce Fuel from Carbon Dioxide and Hydrogen Design standardized to accelerate deliveries and ensure high scalability

https://www.ihi.co.jp/en/all_news/2022/resources_energy_environment/1198178_3488.html