Successful Achievement of 20MPaG Discharge Pressure in a Process Gas Compressor Required for Commercial CCUS to Advance Decarbonization

IHI Corporation (hereinafter “IHI”) and its wholly owned subsidiary IHI Rotating Machinery Engineering Co., Ltd. (Head Office: Koto-ku, Tokyo; President: Keiichi Morikawa; hereinafter “IRM”) have successfully conducted a demonstration test of a process gas compressor that supports decarbonization. In the test, using CO₂ as the working fluid, the companies achieved a maximum discharge pressure of 20MPaG (gauge). This outcome enables the injection of supercritical CO₂ (*1) into deep geological formations such as deep saline aquifers (*2), an essential step for advancing commercial CCUS (Carbon Capture, Utilization and Storage), and contributes to progress in industrial decarbonization.

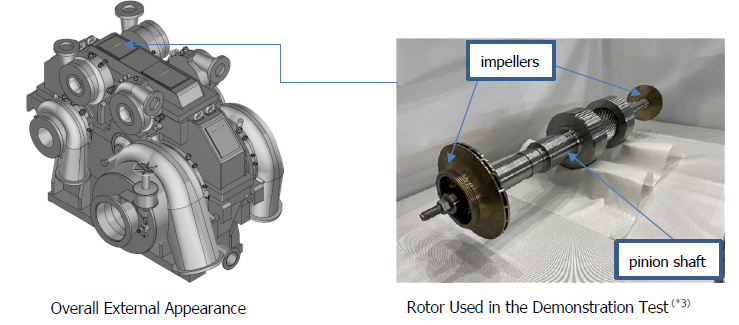

IRM’s process gas compressor lineup includes both turbo‑type (centrifugal) and reciprocating-type compressors. The present demonstration utilized a turbo‑type unit featuring a geared, multi‑shaft, multi‑stage configuration in which multiple pinion shafts are driven by an internal gear system. Unlike single‑shaft, multi‑stage compressors—where all impellers rotate at the same speed—the geared architecture allows stage‑by‑stage optimization of impeller speeds, improving energy efficiency and space efficiency.

IRM manufactures process gas compressors at its Yokohama Factory (Isogo‑ku, Yokohama, within the IHI Yokohama Works). The company leverages world‑class high‑speed, high‑efficiency centrifugal (turbo) technologies and cryogenic gas processing expertise (for reciprocating-types), delivering proven performance and reliability across diverse industrial processes, including air separation units (ASU) (*4) and LNG receiving (import) terminals (*5).

Building on this demonstration as a milestone, IHI and IRM will broaden the application of their compression technologies to processes with high potential to contribute to decarbonization, establish core capabilities across the CCUS and decarbonization value chains, and further enhance system reliability. Through these efforts, the IHI Group will help reduce environmental impact and expand decarbonization‑related infrastructure, contributing to the realization of a more sustainable, low‑carbon society.

[Notes]

(*1) supercritical CO₂: CO₂ above its critical point (31.1 °C, 7.38 MPa). It exhibits gas‑like diffusivity and liquid‑like solvency, which are advantageous for CCUS transport and storage applications.

(*2) geological storage (deep geological formations such as deep saline aquifers): Injection of CO₂ into deep geological formations such as deep saline aquifers—porous formations typically at depths greater than ~800 m—where long‑term storage is achieved via dissolution into formation water and mineralization.

(*3) rotor (for reference): The primary rotating assembly within a turbo compressor consisting of a shaft and impellers that impart kinetic energy to the working fluid for pressurization.

(*4) air separation units (ASUs): Facilities that separate and refine gases (e.g., N₂, O₂) from ambient air for supply to steel, semiconductor, chemical and other industries.

(*5) LNG receiving terminals: Facilities for importing liquefied natural gas, storing it, and regasification for downstream supply.

[Company Profile]

IHI Rotating Machinery Engineering Co., Ltd. https://www.ihi.co.jp/compressor/en/

- Location: 7 12 Shinonome 1-chome, Koto ku, Tokyo 135-0062, Japan

- Representative: Keiichi Morikawa, President

- Capital: JPY 1,033,500,000

- Business Description: Development, manufacturing and sales of compressors, separators, marine turbochargers, and gear devices. Plant engineering, maintenance; and after sales services.