Low Pressure Carburizing with Oil quench

Low Pressure Carburizing with Oil quench

- Low Pressure Carburizing (LPC) with Oil quench is very popular in Japan. This is the technology for Zero CO₂ emission instead of gas carburizing furnace without changing material from low alloy to high alloy. We have been provided this solution as a pioneer.

LPC Feature

- Zero CO₂ emission

- Without IGO

- Good uniform carburizing capability for narrow gap/aperture and deep blind hole

- Ability to carburizing stainless steel

- For low alloy material treated by atmospheric furnace, switching to LPC without changing material.

Test Center

Sample tests are available in Europe and in Japan.

- Carbide-Dispersion Carburizing test is also available in Japan.

Vacuum Hot Press for Diffusion Bonding

Diffusion Bonding Technology

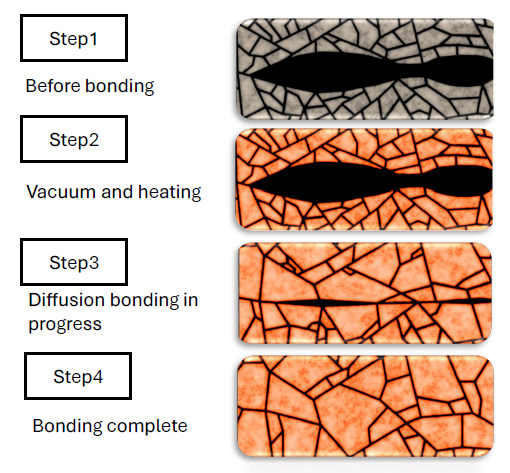

- “Diffusion bonding,” which enables precision bonding, direct, and dissimilar material bonding, has been attracting attention. Diffusion bonding is a method of joining by bringing the components into close contact that cause as little plastic deformation as possible, thereby achieving a metallic bond between the bonded surfaces.

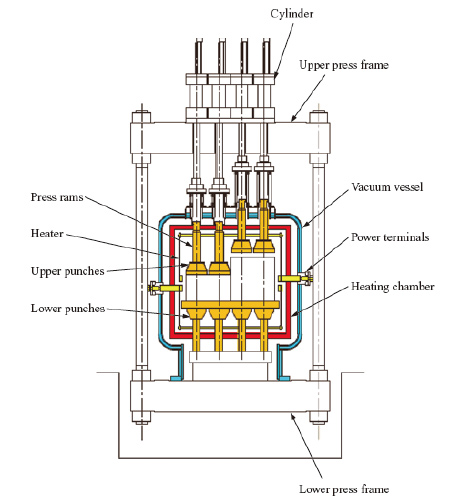

Vacuum Hot Press

- Diffusion bonding is performed using this vacuum hot press. The vacuum furnace has a heating chamber consisting of a heater and heat insulator inside a vacuum vessel made of steel, and a vacuum pump is used to create a vacuum inside the furnace vessel to raise the temperature to over 1000°C to perform heat treatment of steel materials such as quenching and tempering. The vacuum hot press is a vacuum furnace with a press mechanism, and has the structure.

Test Center in Japan

IHI has started a diffusion bonding test service. In order to respond to customer requests for the best bonding method. Based on its accumulated know-how, IMS provides services for each customer development stage, from trial testing to Research and Development (R&D), business studies, and mass production launch.

Click Here For More Info!