IHI Brings Planet Closer to a Carbon-Free Future by Developing World’s First Aircraft Engine-Embedded Megawatt-Class Electric Motor

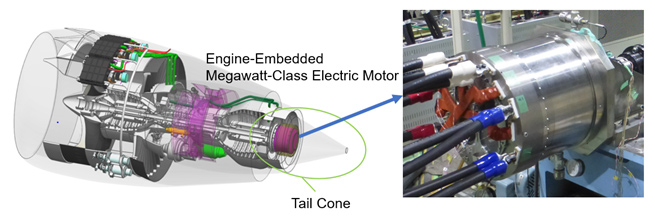

IHI announces today it and several domestic partners jointly developed the world’s first one-megawatt-class (see note 1) electric motor (note 2) mounted inside a jet engine tail cone (note 3). This achievement is one fruit of the company’s More Electric Architecture for Aircraft and Propulsion (MEAAP) project. This technological innovation initiative aims to optimize the overall energy management of aircraft systems, including engines, to help cut their carbon dioxide emissions.

IHI developed this motor as part of R&D into advanced electric propulsion systems and electric hybrid systems under the Research and Development of Advanced Aircraft Systems for Practical Application Project of Japan’s New Energy and Industrial Technology Development Organization.

The global passenger jet fleet should double over the next 20 years on growing travel demand, although the United Nations’ International Civil Aviation Organization targets virtually zero carbon dioxide emissions from these aircraft by 2050. It is accordingly important to improve conventional technologies while innovating aircraft systems that maintain safety and economy and make them more eco-friendly.

The MEAAP project seeks not just to electrify aircraft but also to significantly enhance fuel efficiency by optimizing aircraft systems, including engines, to reuse cabin air, which current designs discharge outside aircraft without using effectively, to cool electrical equipment. This would eliminate the need for complex conventional hydraulic, pneumatic, and other systems, thus boosting design freedom and maintainability while reducing weight. IHI is collaborating with domestic and overseas partners in various R&D efforts to achieve its MEAAP goals.

IHI’s new engine-embedded electric motor could provide power for aircraft and also serve as a key technology in hybrid electric propulsion systems for which R&D is underway around the world.

In March 2020, IHI developed a 250-kilowatt-class engine-embedded electric motor offering the largest generator capacity for currently operating passenger aircraft. At the time, it developed a high-density molded coil technology with a 300°C heat-resistant insulation coating (note 4). It has additionally developed an exhaust heat system technology that taps thermal, fluid, and structural technologies that the company cultivated in jet engine R&D. It has augmented these advances to improve efficiency by overhauling the power generation mechanism to create an electric motor that can deliver more than one megawatt of power. The motor offers output scalability as required.

For its new motor, IHI conducted assessments at the Evaluation Laboratory for Next Generation Motors of the Akita University Joint Research Center for Electric Architecture (note 5). This is the largest such facility in Japan. This work confirmed that the company could attain the anticipated revolutions per minute when connecting the engine shaft directly to the inside of the tail cone.

Motors of the Akita University Joint Research Center for Electric Architecture

IHI will keep developing hybrid electric propulsion systems to electrify aircraft, and looks to demonstrate an engine-embedded electric motor during the middle of this decade. By combining a high-power electric motor for aircraft propulsion (note 6), an electric turbo compressor ( note 7), a high-flux plastic magnet rotor (note 8), and an electric hydrogen turbo-blower (note 9), which are also under development, IHI will electrify and optimize a range of propulsion systems, including hybrid electric propulsion systems for the future, and aircraft systems overall.

Notes

- 1. The one-megawatt-class power level is a global development target for hybrid electric propulsion.

- 2. Here, “electric motor” also includes generators to produce power for aircraft and, ultimately, to drive fans.

- 3. The tail cone behind the low-pressure turbine of a hot jet engine regulates exhaust air flow.

- 4. Press release on March 30, 2020: Development of the world’s first Aircraft jet engine-embedded electric machine with high power density and heat resistant ~For optimizing the energy management of aircraft system to reduce CO2 emission~

https://www.ihi.co.jp/en/all_news/2019/aeroengine_space_defense/1191910_2025.html - 5. Akita University received a regional university and industry creation grant from the Cabinet Office to establish the Joint Research Center for Electric Architecture in April 2021, run jointly with Akita University

- 6. Press release on March 31, 2023: IHI succeeds in developing a prototype of a high-power electric motor for aircraft propulsion systems

https://www.ihi.co.jp/en/all_news/2022/other/1198233_3498.html - 7. Press release on June 16, 2023: IHI Develops One of World’s Lightest and Most Compact Electric Turbo Compressors Incorporating Proprietary Air Bearing Technology that Could Help Materialize Aircraft Fuel Cell Propulsion Systems

https://www.ihi.co.jp/en/all_news/2023/technology/1199839_3531.html - 8. Press release on June 15, 2023: IHI Announces Magnet Rotor for Ultra-High-Speed Motors that Could Revolutionize Performance, Production, and Economy of Electrified Aircraft and Automotive Propulsion Systems

https://www.ihi.co.jp/en/all_news/2023/technology/1199840_3531.html - 9. Press release on November 13, 2023: IHI Demonstrates World’s Highest-Capacity Hydrogen Recirculation System for Aircraft Fuel Cells, Delivering Compactness and High Durability

https://www.ihi.co.jp/en/all_news/2023/technology/1200417_3531.html