Operational technology to achieve advanced automation

- The author's affiliation name is as of the time of publication.

- The information contained in IHI ENGINEERING REVIEW is as of the time of publication.Please note that development and product manufacturing may have been terminated.

Operational technology

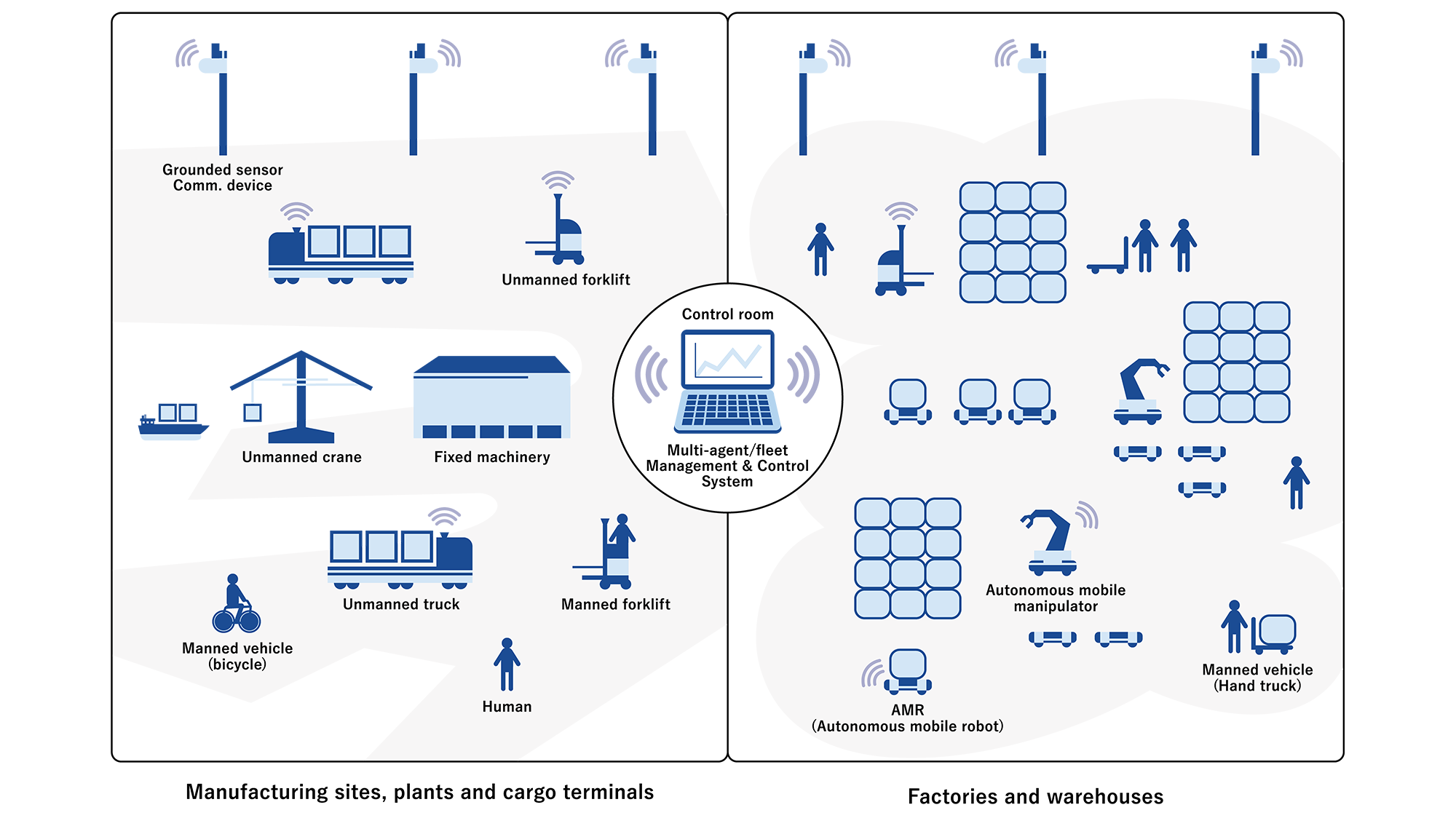

In response to the social environment where labor is in short supply, needs diversify and change rapidly and demands significantly fluctuate, we are developing operational technology to operate and control robots or groups of equipment safely and efficiently by integrating robot technology and information technology. As a system integrator, we aim to provide more valuable robotics solutions for the logistics industry and other various industries.

Operation control of multiple autonomous mobile robots (AMRs) and collaboration between humans and robots

Significant fluctuations in demands bring logistics site the needs of robots with several functions. The functions include the "scalability" to easily increase or decrease processing capacity by changing the number of robots, "flexibility" to easily change transfer routes and positions of robots, and "availability" to continue operation even if some robots stop by using the remaining operable robots. To achieve these three functions in combination, we are developing a system to operate and control multiple AMRs. This system allows AMRs to operate smoothly without contacting each other by monitoring the operating status from the central control side and by recalculating routes according to the delay of AMRs' transfer or delivery and accept processes. In addition, we are conducting the development of technology that satisfies both safety and efficiency to allow AMRs to continue operation even if humans and AMRs exist in the same space. This will meet the needs for the environments where it is difficult to completely separate space or work of humans and robots. Specifically, these technologies are realized by combining the technology to recognize and discriminate obstacles or humans based on the information from various sensors and the control technology such as control barrier function that can impose mathematical constraints on robots not to deviate from a safe state.

System infrastructure for management and swarm control of robots and other automated devices

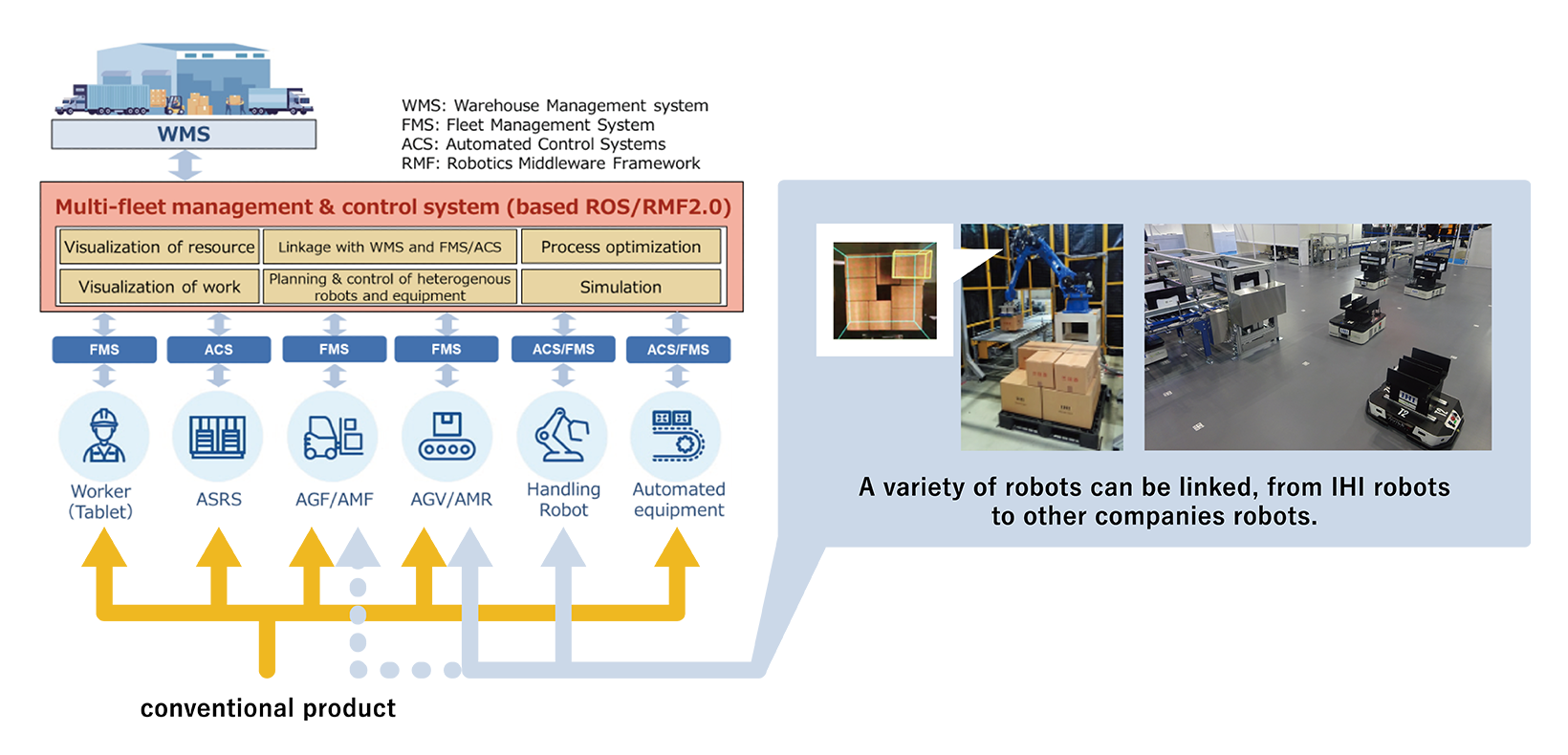

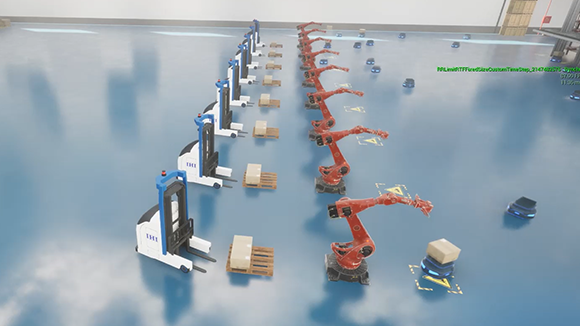

We are proceeding with the development of a system for warehouses and factories to manage and control operations performed in collaboration between around a hundred different kinds of AMRs, handling robots, automated warehouses and their peripheral devices while constructing the development environment for it. To develop a highly interoperable system that can operate various resources including those manufactured by other companies, we are conducting development in collaboration with the ROS-Industrial Consortium Asia Pacific, an organization managed by ARTC/A*STAR, that promotes industrial applications of Robot Operating System (ROS), which is a middleware for robot development and is becoming standard in the robot industry. Under this collaboration, we are developing a system to commonly handle various communications, a database to centrally manage information, a function to break down robot operation into tasks and schedule the tasks, and a simulator to visualize the entire operation. Currently, we are promoting applications in the production and logistics industries with high demands, but in the future, we will make these management and control technologies serve as the foundation of various businesses with a view of applying them to the operation of numerous unmanned machines in dangerous areas for the defense or nuclear sectors and to the management, inspection and maintenance for energy-related facilities.

credit: ROS-Industrial Consortium Asia Pacific