Electric TurboCharger(ETC) for hydrogen-based fuel cell systems

- What is ETC?

- What is the main function of ETC?

- What are the main types of

compressors for FC systems? - IHI ETC strong features

- IHI ETC series lineup

- Contact

What is ETC?

We must solve problems related to global warming and realize a sustainable society for the next generations. IHI aims to realize a highly efficient fuel cell system to help achieve a carbon-neutral society. IHI has developed the world’s first Electric Turbocharger (ETC), fully utilizing our experience and technology.

What is the main function of ETC?

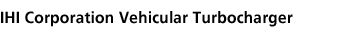

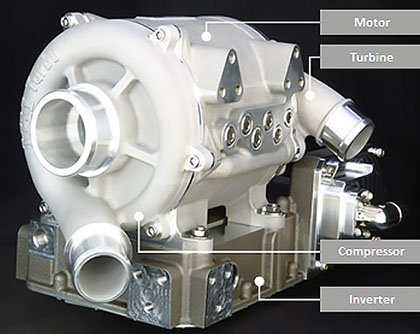

ETC consists of a compressor, a turbine, a set of bearings, a motor, and an inverter.

The compressor and turbine are coaxially arranged and driven by the centrally located motor controlled by the inverter.

The fuel cell converts chemical energy to electrical energy by electrochemically reacting hydrogen in the fuel with oxygen in the air. A compressor is used to efficiently supply this air. The turbine converts the energy into rotational energy by recovering enthalpy from the steam discharged from the FC stack.

This structure enables the motor to consume less power while achieving a smaller size, contributing to the higher efficiency of the fuel cell system.

What are the main types of compressors for FC systems?

Generally, compressors are classified into two types: positive displacement type and turbo type. IHI uses centrifugal (turbo) compressors as the air supply source for its fuel cell systems. IHI considers a centrifugal compressor as the most efficient solution for fuel cell air supply system based on the more than 20 years of experience.

IHI ETC strong features

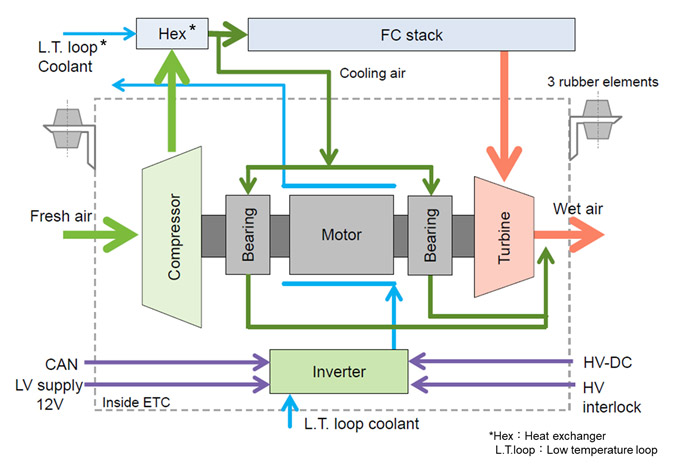

◎Oil-free machine

IHI ETC provides a solution for the oil contamination on the FC stack

◎Mechatronic integration structure

IHI ETC realizes miniaturization by integrating the motor and inverter.

◎Electrical compressor with turbine assist

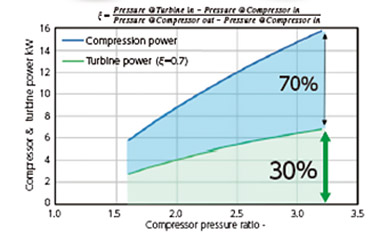

Turbine provides 30% of the power required to drive the ETC compressor by recovering the energy exhausted from FC stack, which enables downsized and less power consumption ETC.

◎Stop/start operation capability

ETC is designed for automotive use that start-stop operation for fuel-efficient driving mode is within the development boundaries.

◎High power density

Power density (out power per unit weight) is improved by 58% from our first ETC introduced in the market, thanks to the successful downsizing of inverter.

IHI ETC series lineup

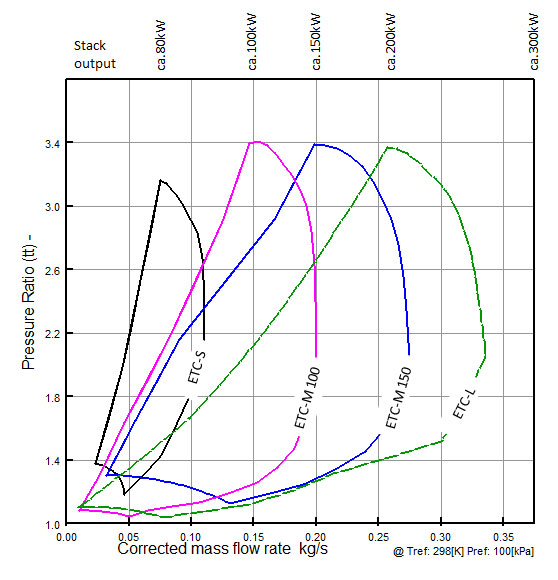

IHI offers the product line up from S size to L size depending on the FC stack output power. Multiple ETCs can be used in case of higher output power.

In addition, tailored ETC aero parts provide maximum efficiency.

| ETC-S | ETC-M 100 ETC-M 150 |

ETC-L | |

| Motor output power | 11kW | 20kW | 30kW |

| Turbine power(Reference value) | 3.5kW | 6kW | 9kW |

| Max.speed | 100,000rpm | 115,000rpm | 90,000rpm |

| Transient spec. ldle to 90% | 1.3sec. | < 1.3sec. | < 2.0sec. |

| Coolant | 6L/min,70℃ | 10L/min,70℃ | 15L/min,70℃ |

| HV voltage | 250-450V | HV3 equivalent 520-750V | HV3 equivalent 620-850V |

The following graph (corrected mass flow rate and pressure ratio of compressors) shows the sizing of the ETC lineup related to the output of the fuel cell system. We offer a lineup that covers a variety of requirements.

Contact

We will be your partner in developing your system through ETC. Please feel free to contact us when you are considering an air supply source for your fuel cell system.