Turbocharger for ICE

- Outline

- Product lineup

- Wastegate Turbocharger

- RHZ Series Turbocharger

- VGS Turbocharger

- RHV EX Series Turbocharger

- Electric motor

assisted turbocharger

for 48V mild-hybrid system - Supercharger

Outline

Environmental legislation is becoming more and more stringent and requires a significant reduction in the fuel consumption and pollutant emissions caused by future vehicles.

Apart from exhaust treatment or optimized combustion procedures, supercharging internal combustion engines is a major contribution towards achieving this end. It allows for the so-called downsizing which means that a comparable performance can be generated by using engines that have a smaller piston displacement and/or fewer cylinders. This increases engine efficiency as it considerably reduces losses by internal friction.

Supercharging an internal combustion engine always requires a compressor to deliver the fresh air flow under high pressure. Supercharging systems differ by the method used for driving the compressor. This can be done by a separate electric motor (Electric Compressor), by direct coupling to the crankshaft (supercharging) or by using a turbine to withdraw energy from the exhaust gas which would otherwise escape to the atmosphere without being used (turbocharging).

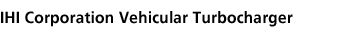

IHI Turbocharger Product lineup

Turbocharger technology

Turbochargers must be able to function efficiently over a relatively wide operating range of an internal combustion engine. This requires controlling of the turbocharger. Wastegate (WG) turbochargers and variable geometry system (VGS) turbochargers are the two most utilized concepts.

Wastegate Turbocharger

In WG (Wastegate) turbochargers, a valve is used to release excessive exhaust flow past the turbine wheel. When the turbo boost pressure is about to increase excessively, the WG valve opens instantly to release exhaust gases, thereby protecting the engine.

WG turbochargers made by IHI are available in a wide variety of manufactured sizes and cover an engine power range from 40 to 300 kW over (per turbocharger).

They run on bearings presenting very low friction, can be equipped with mixed-flow turbine wheels and have highly efficient compressors.

Turbochargers will be configured individually as per customer request and are usually optimized to ensure quick response characteristics and the required maximum engine performance.

To further reduce fuel consumption and emissions, IHI also offers multi-flow turbines in addition to the single-flow turbines available on a standard basis.

Pneumatic actuators (positive and negative pressure type) and electric actuators are used to open and close the WG to provide precise engine control.

RHZ Series turbocharger

The RHZ series turbocharger is a new standard for RH, developed in anticipation of future global development trends in internal combustion engines.

In order to satisfy the engine performance in each power band required in the future and the corresponding turbo performance, we have reviewed the size and the corresponding power band configuration from the conventional turbo by utilizing model-based development.

The RHZ turbocharger has a wider operating range, higher pressure ratio, and higher efficiency by increasing the compressor speed, strengthening the structure, and revising the turbine blade shape.

Response has been improved by reducing the inertia of the rotating elements (turbine, shaft, and compressor) while employing low-friction bearings compatible with low-viscosity oil.

As a result, the turbocharger as a whole has been made more compact and lighter, while balancing the conflicting elements of performance and strength.

For a more detailed explanation, please refer to the following link.

VGS Turbocharger

VGS turbochargers, on the contrary, present movable guide vanes upstream of the turbine wheel to help optimize the flow conditions approaching the turbine wheel.

Even when the engine revolution speed is low and the exhaust gas flow rate is low, the exhaust gas can be sent to the turbine efficiently by narrowing the opening angle of the guide vanes. As a result, it contributes not only to improved low-speed engine torque and acceleration, but also to lower fuel consumption and particulate matter (PM) emissions.

VGS turbochargers made by IHI are available in a wide variety of sizes and cover engine power ranges from 70 to 300 kW over (per turbocharger). To improve manufacturability and installation, the movable guide-vane mechanism has been designed in a cartridge form.

This system is known for its very high reliability and has been optimized further by reducing leakage flows in the latest stage of development.

RHV EX Series Turbocharger

The RHV*EX series is the world's only turbocharger for commercial vehicles equipped with a VGS for Exhaust Brake.Among commercial vehicles, many medium- and heavy-duty trucks, especially those that carry a large volume of freight, are equipped with an exhaust brake as a supplement to the normal foot brake.

The exhaust brake system closes the valve that closes the exhaust pipe, thereby creating strong exhaust resistance in the engine and exerting braking force.

At the same time, the turbocharger between the engine and the exhaust brake is subjected to high stresses, such as vibration, from the exhaust gases that have nowhere to go after the valve closes.

This stress can cause friction and wear on the turbocharger components. In particular, the precision mechanism of the VGS turbocharger is susceptible to friction and wear and can cause problems, so most turbochargers for commercial vehicles on the market omit the VGS mechanism.

IHI has optimized the structure of the VGS, the selection of materials for its components, and the surface treatment for the exhaust brake to achieve a turbo that can benefit from the VGS even in commercial vehicles.

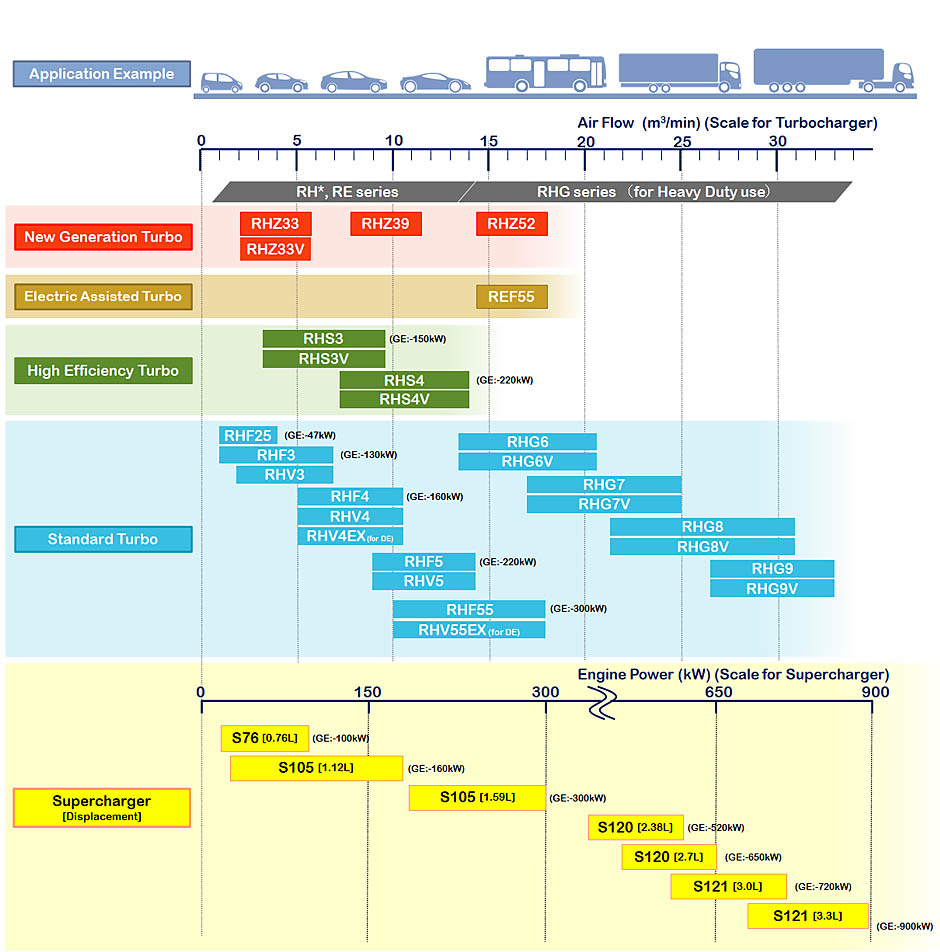

Electric motor assisted turbocharger for 48V mild-hybrid system

The electrical components of the REF TC are placed between the modular bearing system and the compressor wheel, offering thermal separation from the hot turbine side and simple assembly in mass production. By instantly assisting the turbocharger to increase its rotation, the turbocharger can accelerate and boost pressure can be increased in a very short time, which is not possible with conventional turbochargers, even when the exhaust gas energy is small.

Faster boost pressure increase leads to improved torque response to accelerator pedal operation for the engine and vehicle, resulting in improved drivability and reduced fuel consumption rate.

The REF can also regenerate energy, and when there is sufficient exhaust gas energy, the electrical energy generated can be stored in a battery.

In addition to being used in high-performance cars that emphasize drivability, it is also expected to contribute to improving the system efficiency of hybrid cars and eco-cars such as PHEVs in the future.

For a more detailed explanation, please refer to the following link.

Supercharger

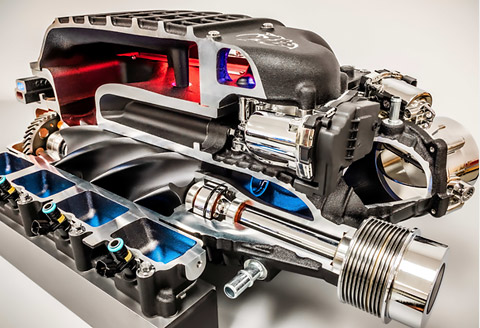

IHI utilizes high-efficiency positive displacement screw compressor technology in its superchargers. Screw compressors do internal compression, which results in high isentropic efficiency and lower parasitic losses than other technologies.

This type of supercharger is compact and since it is mechanically driven provides rapid boost response. Other positive displacement devices simply pump a volume and rely on external compression to generate boost requiring more power from the engine crankshaft.

A screw compressor (two helical rotors) synchronized with the engine speed compresses air quickly and feeds it to the engine for outstanding response.

A wide variety of options are available, including electromagnetic clutches and other drive systems, as well as internal lubrication systems.

For a more detailed explanation, please refer to the following link.

Contact

Please feel free to contact us when you are considering a turbocharger for engines.