Challenge aimed at decarbonization through ammonia utilization technology

- The author's affiliation name is as of the time of publication.

- The information contained in IHI ENGINEERING REVIEW is as of the time of publication.Please note that development and product manufacturing may have been terminated.

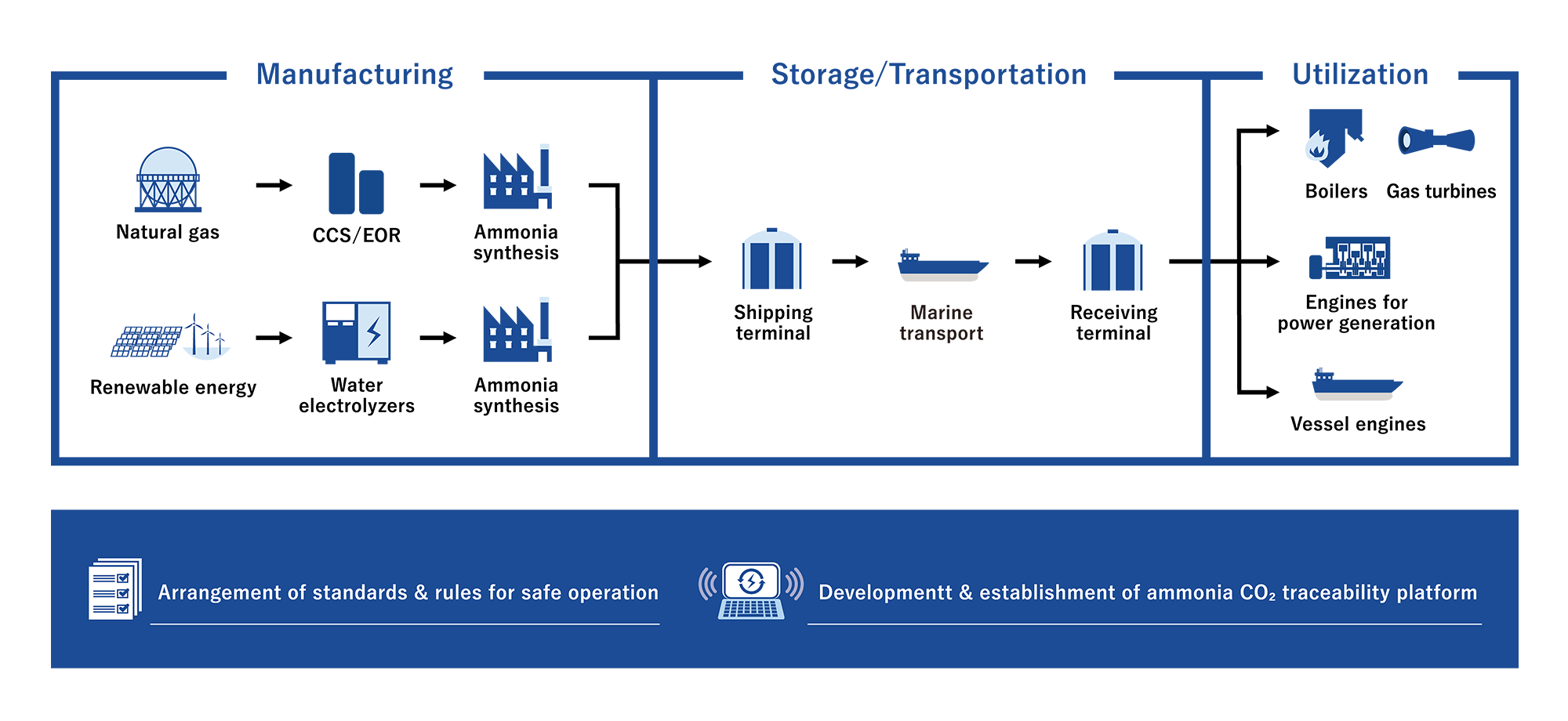

Ammonia value chain

We have been focusing on the utilization of ammonia to provide sustainable solutions to energy problems. Ammonia is easy to transport and store and does not emit CO₂ when burned. These characteristics allow ammonia to be an attractive alternative to fossil fuels. As ammonia can serve as a hydrogen carrier as well as a fuel, it is expected to be versatile in the energy field.

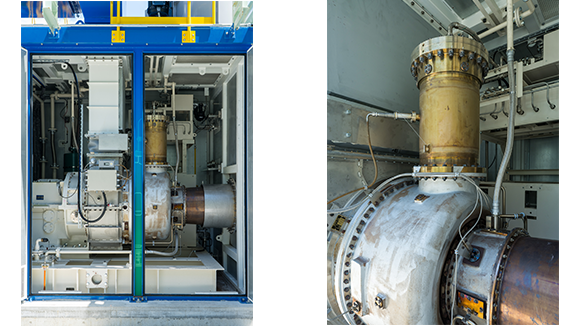

Ammonia gas turbines

We have developed an ammonia-fired combustor for the IHI-manufactured IM270 gas turbine with rated output of 2 MW and successfully demonstrated liquid ammonia single firing. While conducting a long-term durability test at the Aioi Works, we are on the way to technology development for larger gas turbines.

- This contents is based on results obtained from a project, JPNP21020, commissioned by the New Energy and Industrial Technology Development Organization (NEDO)

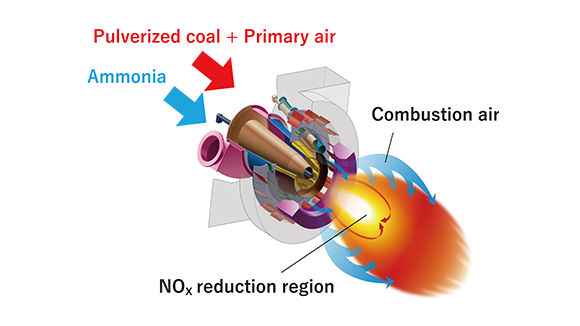

Ammonia boilers

To achieve decarbonization in the energy field, we are working on ammonia substitution for existing large-scale coal-fired power generation boilers. In 2024, we completed the large-scale demonstration test using IHI-developed ammonia burners at the Hekinan Thermal Power Station of JERA Co., Inc. We work on technology development with the goal of higher substitution rates.

- This contents is based on results obtained from a project, JPNP16002, subsidized by the New Energy and Industrial Technology Development Organization (NEDO)

Related articles

- Vol. 55 No. 1 (2022) Carbon-Neutral Thermal Power Generation Using Ammonia

- Vol. 57 No. 1 (2024) Development Status of Ammonia Combustion Technology Various initiatives aiming to expand the use of ammonia fuel to reduce CO₂ emissions

- Vol. 57 No. 1 (2024) Popularizing Ammonia Combustion Technology from Japan Initiatives to expand the use of ammonia and application of ammonia utilization technology to existing boilers

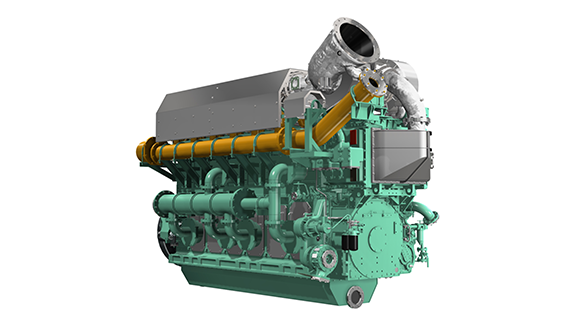

Ammonia-fueled engines

Aiming to achieve zero emissions of CO₂ from vessels, we are developing marine engines fueled by ammonia. Ammonia-fueled marine engines make it possible to construct an ammonia value chain, which is estimated to require the high demand for marine transport, without increasing CO₂ emissions.

- This contents is based on results obtained from a project, JPNP21031, subsidized by the New Energy and Industrial Technology Development Organization (NEDO)