Sustainable Fuels and Chemicals by CO₂ Recycling

IHI Corporation

Cover Message

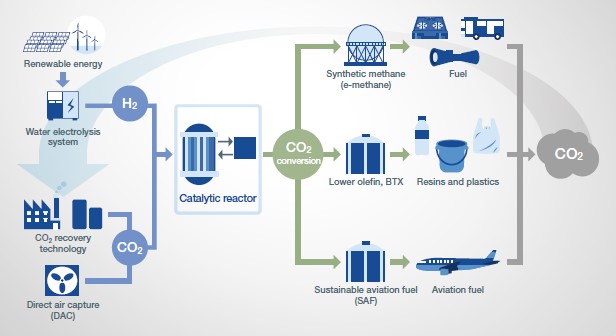

The IHI Group is developing carbon recycling technology that converts carbon dioxide (CO₂) into greener fuels and chemicals, aiming to eliminate the use of fossil resources. Our goal is to produce fuels and chemical raw materials currently derived from fossil resources using CO₂. Through such means, we will continue to contribute to a future where CO₂ can be recycled.

A new approach to converting CO₂ into fuels and chemicals

The fuels that support our daily life, such as city gas and gasoline, and materials and chemical products like resins and plastics, are mostly made from fossil resources. Meanwhile, it is said that the increase in CO₂ emissions is a major factor in global warming and approximately 85% of CO₂ emissions come from fossil resources, making it an urgent priority to reduce the use of them. In the power generation sector, the main measures include expansion of renewable energy as well as introduction of alternative power generation methods using green hydrogen and ammonia fuel, which do not emit CO₂ when burned. While such measures are being rapidly advanced, they are not as effective in some sectors: those that require high energy density fuels, materials, and chemical raw materials. In these sectors, substances called hydrocarbons, which are composed of hydrogen and carbon, are made from fossil resources, and replacing them with electrification is fundamentally extremely difficult.

Under these circumstances, the IHI Group is currently focused on developing technology to synthesize hydrocarbons from CO₂ instead of fossil resources. The technology to convert CO₂ into fuels and chemical raw materials will allow us to produce the hydrocarbons needed in various industries.

The potential of carbon recycling technology

CO₂ is the final product generated from the use of fuels and the incineration of used resins and plastics. Carbon recycling technology involves capturing this final product, or CO₂, and recycling it as a resource. It is considered that this would offset the CO₂ emissions generated during the manufacturing process, use, and incineration, significantly reducing the carbon footprint over the entire product lifecycle. Furthermore, by applying technology to capture CO₂ directly from the air (Direct Air Capture), there is a possibility of achieving a carbon negativity, where the amount of CO₂ absorbed from the atmosphere is greater than the amount of CO₂ emitted.

In particular, the IHI Group’s focus in carbon recycling technology is synthesis methods for fuels and chemical raw materials, which utilize methanation and the Fischer-Tropsch (FT) reaction.

Methanation: Converting CO₂ into an energy source

Methanation is a method of manufacturing synthetic methane (e-methane), using CO₂ as a raw material. Methane, which is a main ingredient of natural gas, is used as a power generation fuel, city gas for households, as well as a heat source in various industrial manufacturing processes, and it is expected to contribute to carbon neutrality in these sectors.

The IHI Group considers that our methanation technology is versatile due to its independently developed catalyst with excellent heat resistance. For example, we investigate converting CO₂ emitted during cement production and CO₂ contained in biogas generated from sewage sludge into e-methane to effectively use it as fuel. Additionally, this technology has been implemented to supply fuel for mobility. One example is the e-methane supply project for the community bus “Odekake Minibus” (Soma City, Fukushima Prefecture).

Fischer-Tropsch reaction (FT reaction): Producing hydrocarbons from CO₂

The FT reaction is originally a reaction process that synthesizes hydrocarbons, which are the basis for materials and liquid fuels, using syngas composed of hydrogen and carbon monoxide (CO) as raw materials. We are working on developing a hydrocarbon synthesis technology using the principle of the FT reaction with CO₂ as the raw material instead of CO. While methanation selectively synthesizes methane with a single carbon atom, directly hydrogenating CO₂ through the FT reaction allows the synthesis of hydrocarbons with two or more carbon atoms. The IHI Group is focusing on the development of catalysts and processes that efficiently promote this reaction. The iron-based catalyst developed by the IHI Group allows the selective synthesis of hydrocarbons, particularly lower olefins, from CO₂. Lower olefins are raw materials for resins and plastics. Further processing of synthesized lower olefins can produce heavy hydrocarbons suitable for use as a liquid fuel. Therefore, we consider their use as a sustainable aviation fuel (SAF). Additionally, by working on the synthesis of aromatic hydrocarbons such as benzene, toluene, and xylene, known as BTX, we aim to produce raw materials for many chemical products and replace all fossil-derived products with those derived from CO₂.

Conclusion

The IHI Group is developing carbon recycling technology that converts CO₂ into more useful materials. With this technology, we aim to eliminate dependence on fossil resources by producing all fuels and chemical raw materials using CO₂.

Although the IHI Group’s research is still progressing toward this goal, we are striving daily to develop new technologies to produce materials and energy to support people’s daily life while protecting the global environment.