Sustainable Fuels and Chemicals by CO₂ Recycling

- IHI Corporation

Change

Location

Currently Using The English Site.

Regional HQ’s Websites

Other

1.Realization of CO₂-Free and Recycling-Oriented Society

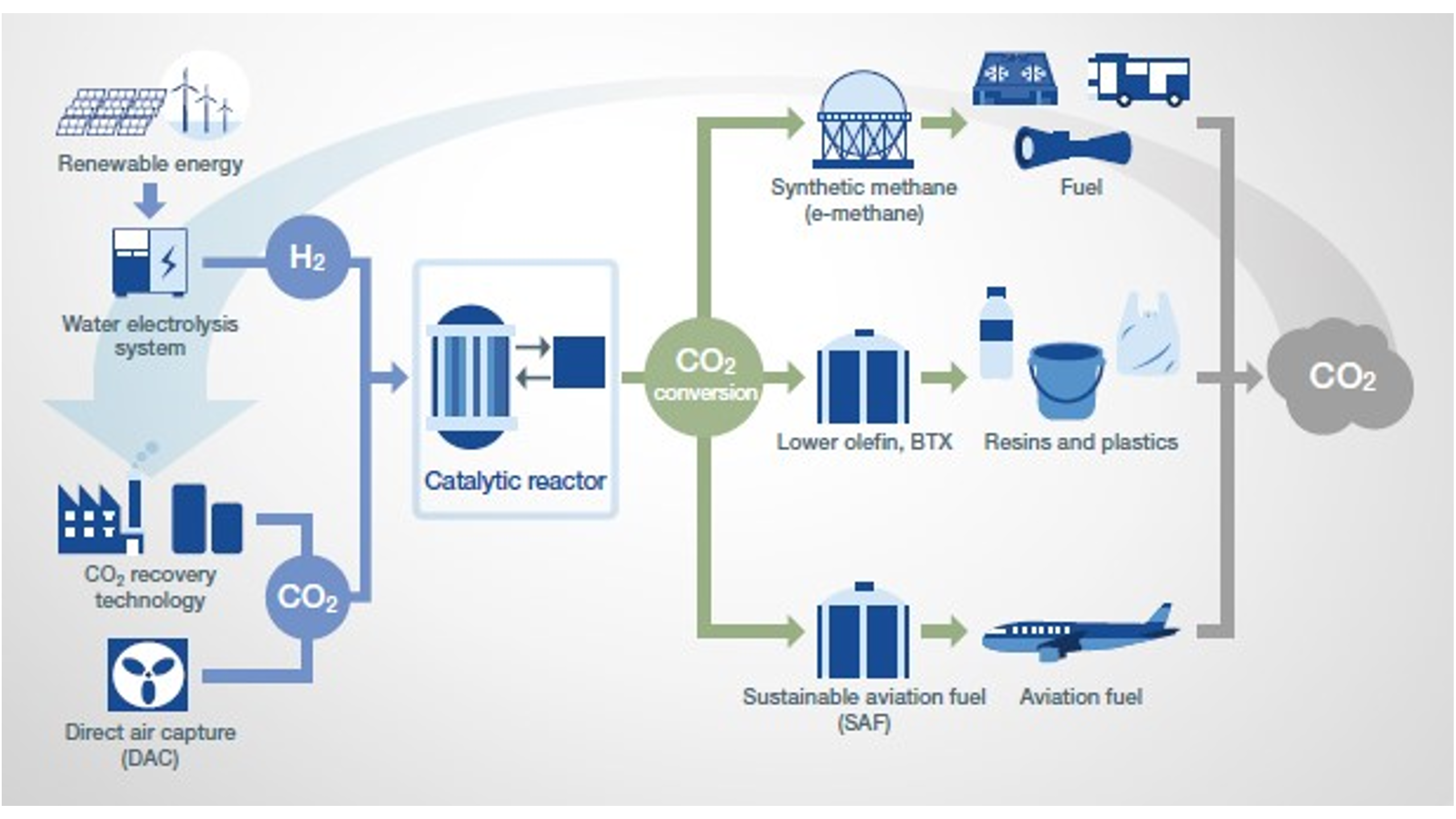

Sustainable Fuels and Chemicals by CO₂ Recycling

Reduction of CO2 with IHI's High-Speed Carbonization Technology: Soil carbon sequestration system

2.Promotion of Digital Transformation

3.Technological Innovation

Technologies for Replacement of Bridge Slabs

Development of Circulating Fluidized Bed Thermal Energy Storage (CFB TES) System

Sustainable Fuels and Chemicals by CO₂ Recycling

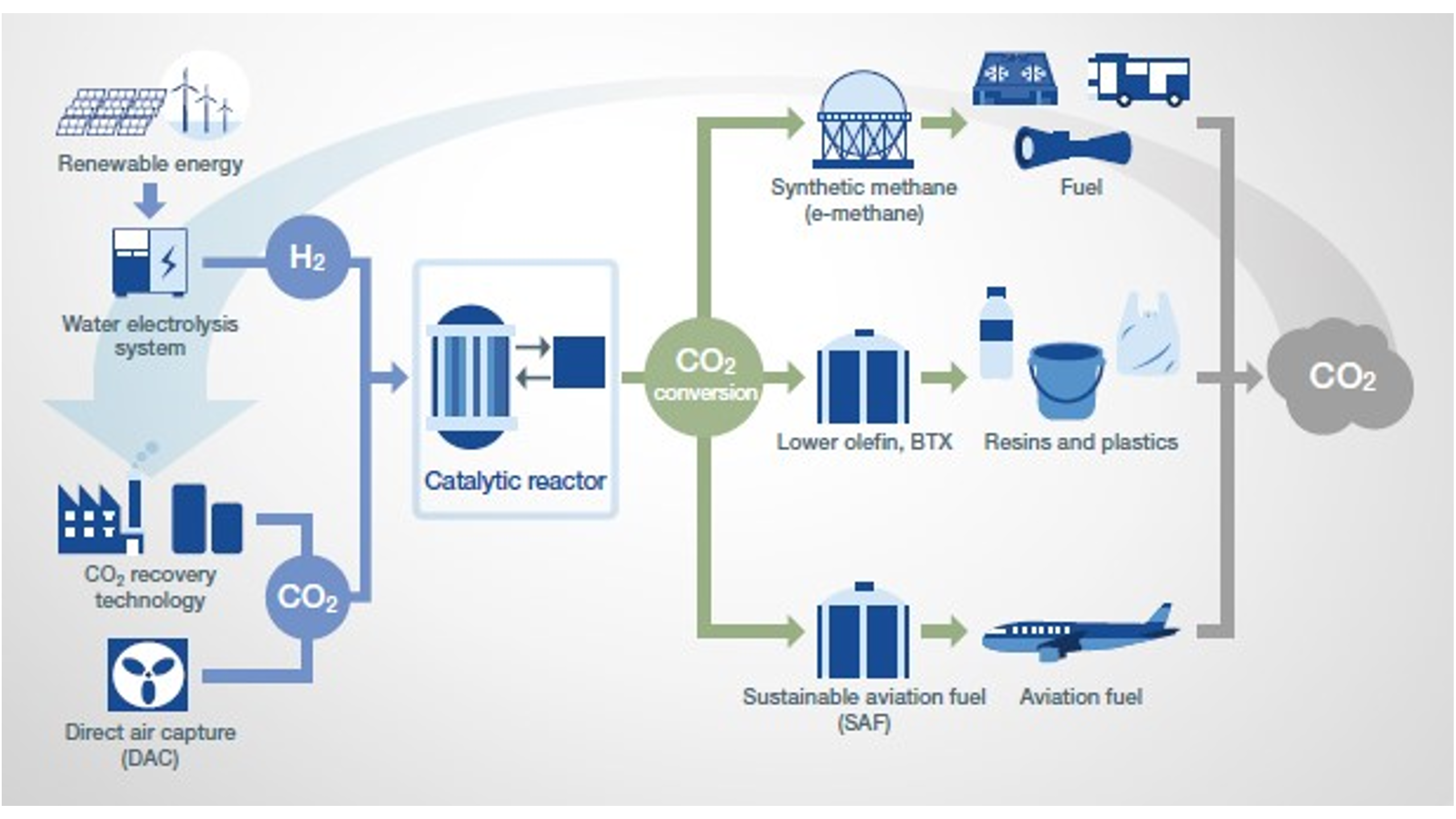

A New Challenge by IHI to Quantitatively Understand Energy Scenarios

Simulating how energy-related technologies will potentially be adopted from an economic perspective

The IHI Group has started a new initiative to utilize economic simulations as it plans to deploy technologies and services related to the environment and energy. Using sustainable aviation fuel (SAF) as an example, we will introduce our initiatives for predicting future energy trends.

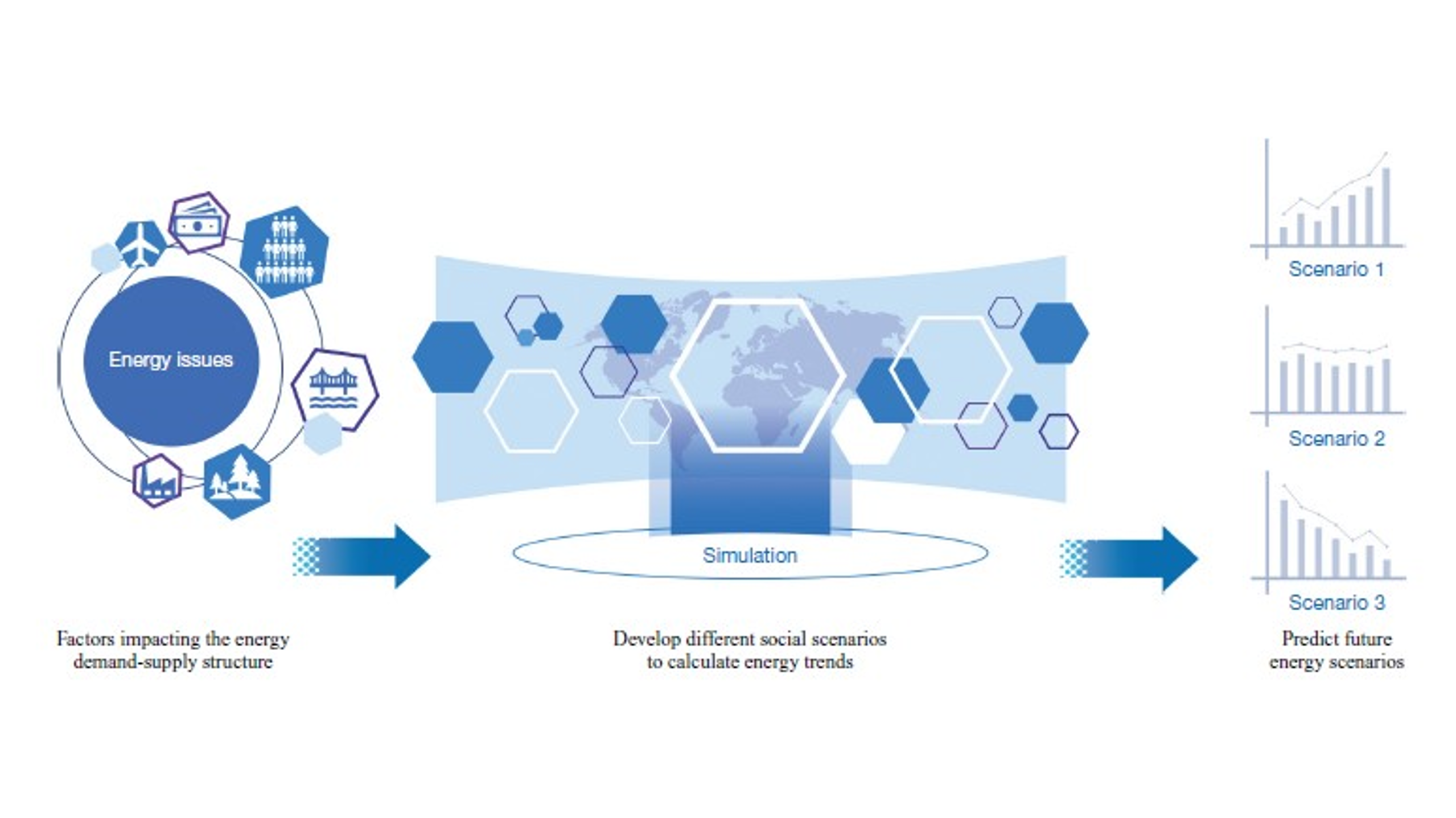

Successful Demonstration Test of Ammonia Firing Conducted at Commercial Power Station

Results of demonstration test for ammonia 20% firing at Hekinan Thermal Power Station Unit 4

The IHI Group has made efforts to introduce ammonia, which does not emit carbon dioxide (CO₂) during combustion, as a fuel for pulverized coal-fired boilers and gas turbines, providing an effective means to achieve carbon neutrality at thermal power stations. Technological developments have been made to address the challenges of achieving stable and low nitrogen oxides (NOx) combustion posed by the properties of ammonia. As the culmination of its development efforts, IHI, in collaboration with JERA Co., Inc., successfully conducted a demonstration test of ammonia 20% firing at Unit 4 of the Hekinan Thermal Power Station of JERA, marking a significant first step towards commercialization.

Achieving Carbon Neutrality in Chemical Industry

Development of an ammonia single-firing burner for naphtha cracking furnaces

To achieve carbon neutrality in the chemical industry, IHI developed a burner fueled only by ammonia for naphtha cracking furnaces to reduce CO₂ emissions from such furnaces. Development was conducted in a basic combustion test furnace at the Development & Demonstration Park (D&D Park) in the IHI Aioi Works, and it was confirmed that the burner satisfied the specified performance.

Small Modular Reactor (SMR) to Contribute towards Decarbonization

Features of NuScale VOYGR SMR and technological development status in IHI

In recent years, the development of small modular reactors (SMRs), which have lower output than conventional nuclear reactors, has been actively pursued by various countries. It is considered that SMRs have the next-generation technologies suited to realize a decarbonized society. IHI has been engaged in the technological development of the VOYGR SMR power plants, developed by NuScale Power, LLC. in the United States. This article presents the updated development status of the VOYGR SMR.

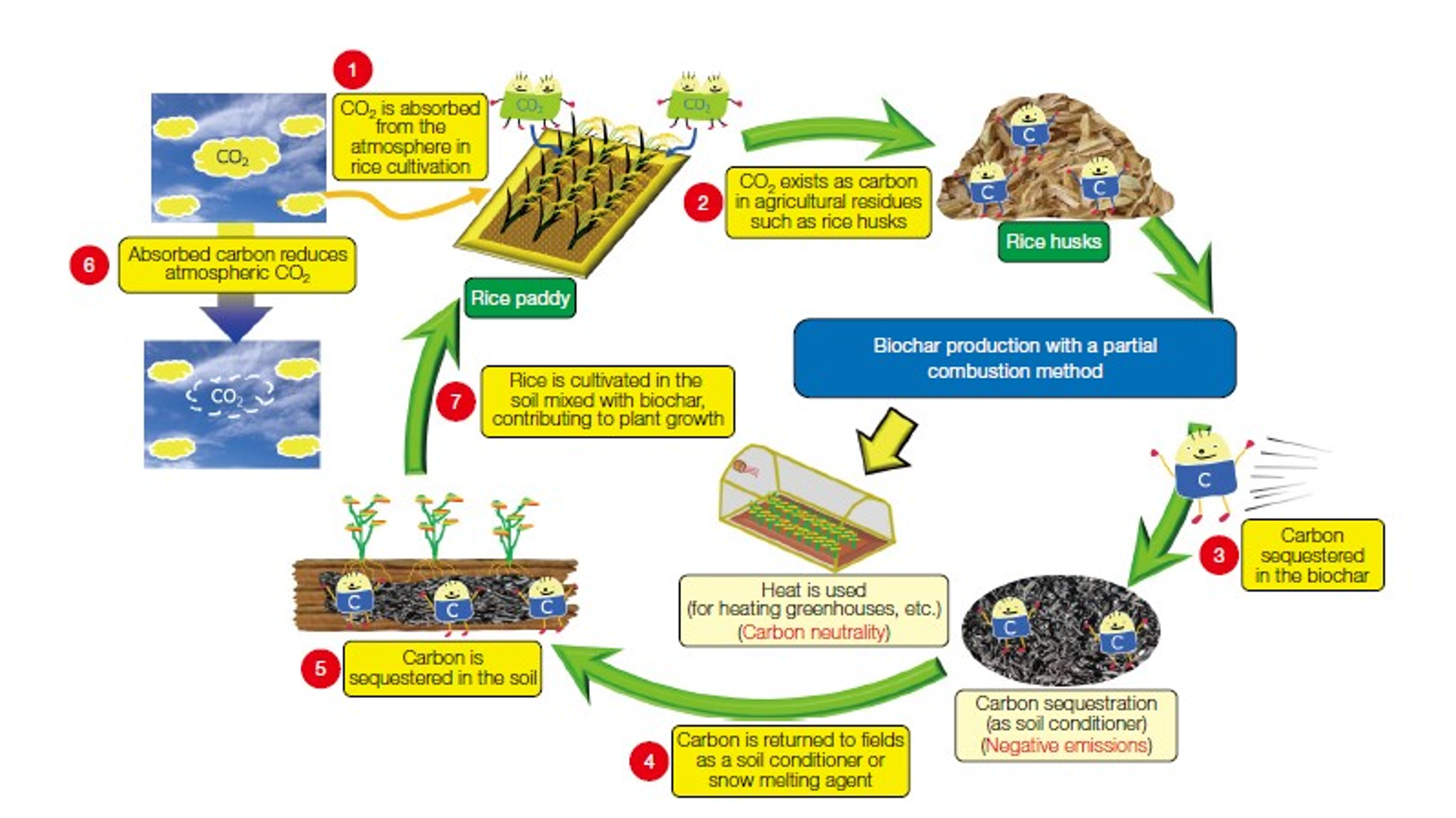

Reduction of CO2 with IHI's High-Speed Carbonization Technology

Soil carbon sequestration system

IHI is developing a soil carbon sequestration system to reduce carbon dioxide (CO₂) by producing biochar from plants that have absorbed CO₂ from the atmosphere through photosynthesis and fixing the biochar in the soil. If the heat generated by the biochar production process is used to substitute heat derived from fossil fuels, it can further contribute to CO₂ reduction.

Using Large Language Models to Achieve DX

Developing Chat-IHI, an environment based on ChatGPT, and using it in business

The IHI Group is making use of generative AI, including large language models (LLMs), to achieve digital transformation (DX). This article introduces the three phases of the IHI Group's LLM utilization and the specific initiatives involved in each of these phases.

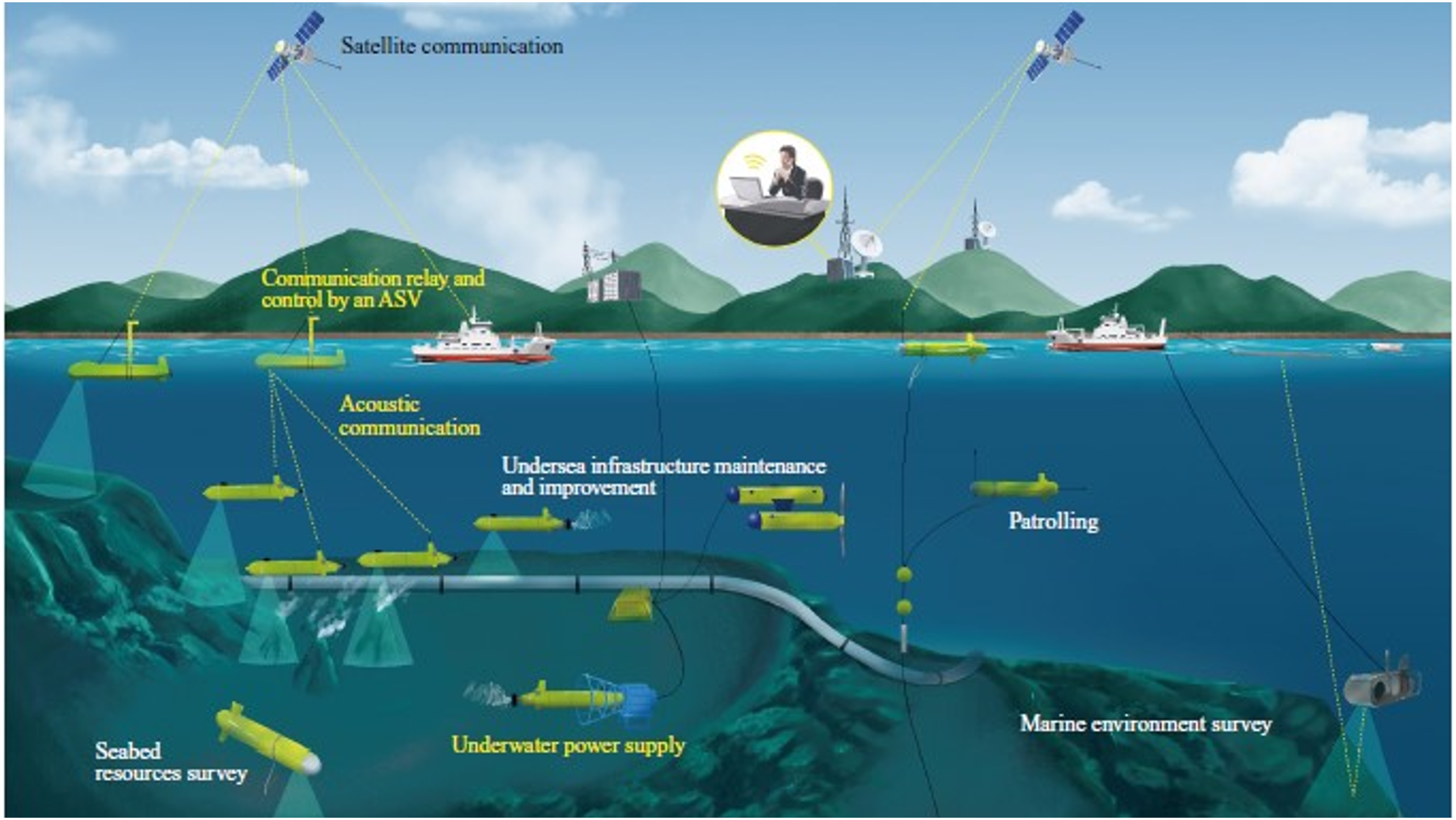

Contributing to Marine Safety via Infrastructure Inspections and Seafloor Surveys

IHI's AUV technology to spearhead next-generation marine industries

An autonomous underwater vehicle (AUV), also called an underwater drone, is a robot that can navigate unmannedly and autonomously underwater and undersea at depths that are difficult for humans to reach. This article introduces the functions, structure, and control of these AUVs using IHI's AUV as an example.

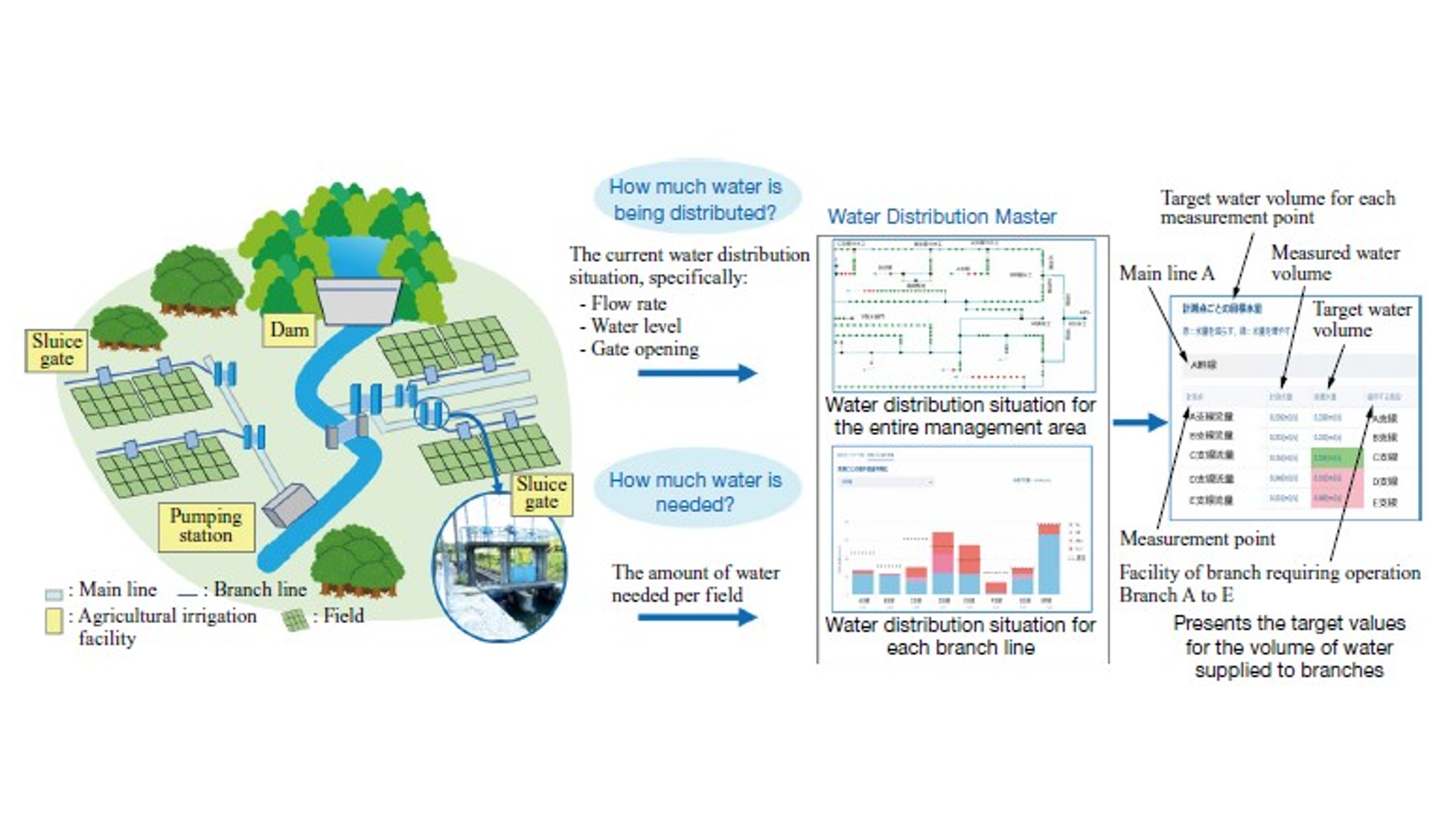

Transition from Experience-Based Water Distribution Management to a Data-Driven Approach

Water Distribution Master —A tool that supports water distribution for optimized agricultural water management—

Water Distribution Master, developed by IHI, is a tool that visualizes the uneven water distribution across each branch line of water at a rice field and presents solutions to resolve the uneven distribution. Using the results from this tool, water distribution managers can optimize agricultural water distribution and reduce water waste.

Technologies for Replacement of Bridge Slabs

As bridges in Japan are aging, replacement works are conducted for slabs directly subjected to the load of passing vehicles. Many works conducted so far did not have much difficulty caused by bridge conditions, but more and more difficult works must be conducted in the future. In order to complete such works with a variety of severe conditions, the IHI Group has developed technologies for facilitating replacement of slabs. This paper introduces these technologies briefly.

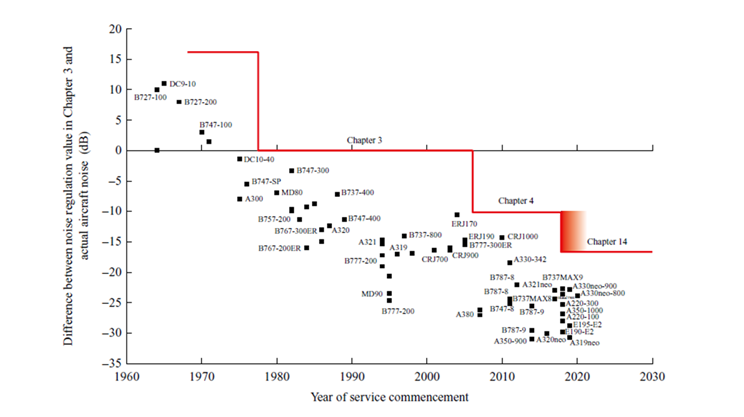

Component-Level Technology Demonstration of Resin-Based Lightweight Acoustic Liner on the JAXA F7 Engine Testbed

The acoustic liner is one of the most essential devices for reduction of noise emitted by high bypass ratio turbofan engines. IHI has developed and demonstrated lightweight acoustic liner technology utilizing thermoplastic resin for a future turbofan engine together with Japan Aerospace Exploration Agency (JAXA). In 2022, the component-level technology demonstration was conducted with the acoustic liner mounted on the F7-10 engine testbed of JAXA. The demonstration showed that the acoustic liner can achieve the sound absorption performance and structural soundness under actual engine operating conditions. It was also successfully demonstrated that the manufacturing technology was established to ensure both the lightweightness and structural strength enough to be used under engine operating conditions.

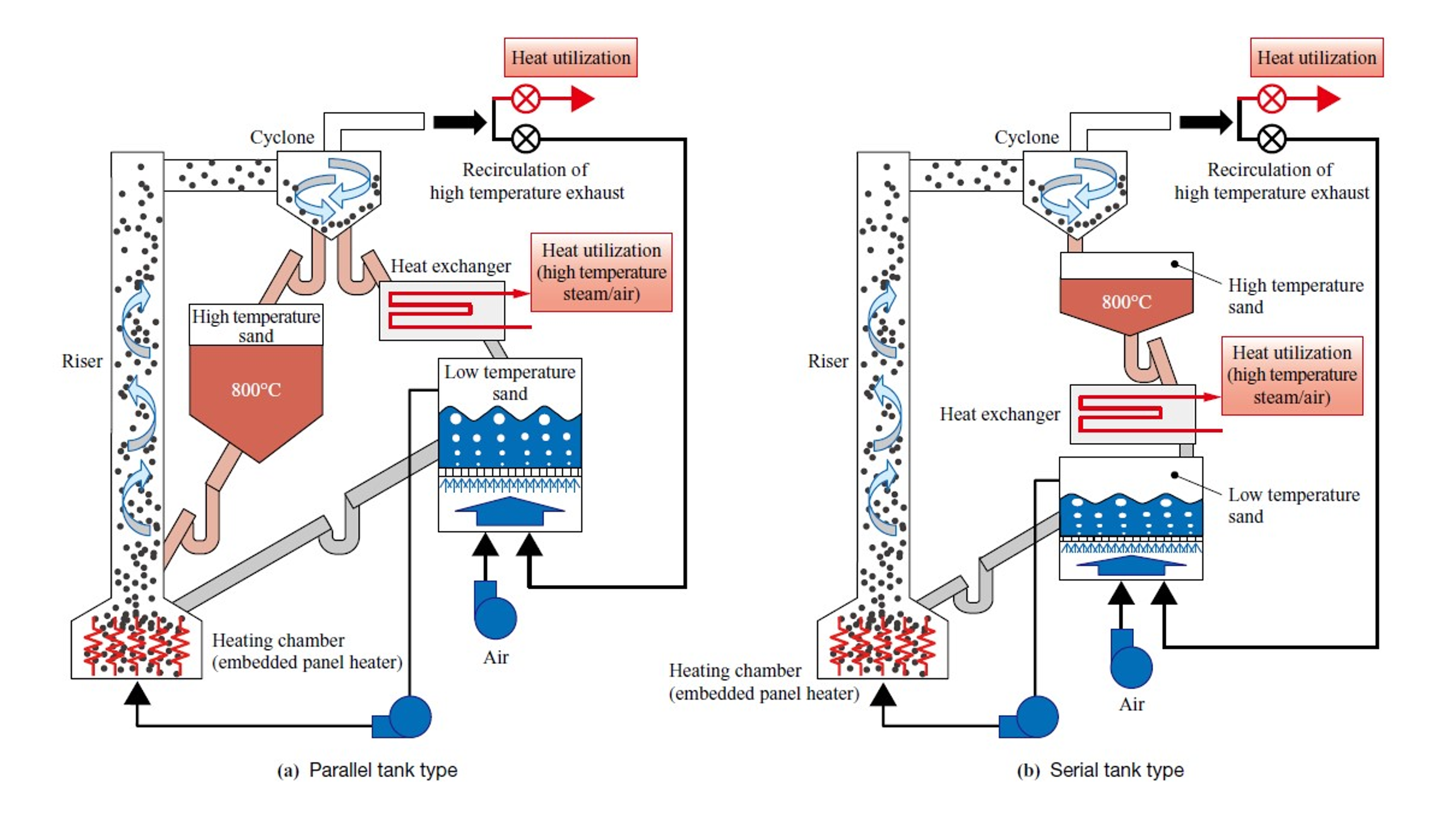

Development of Circulating Fluidized Bed Thermal Energy Storage (CFB TES) System

Green electricity derived from renewable energy is essential for achieving carbon neutrality. Since the output of renewable energy is unstable, energy storage is required to ensure a stable supply, but the energy storage systems currently in use have drawbacks such as high cost, location constraints, and resource constraints. To solve these problems, IHI, in collaboration with Tsinghua University, developed a thermal storage system that utilizes fluidized bed technology as a large-scale, inexpensive energy storage system. The heat storage material used was silica sand, which is a heat medium commonly used in fluidized bed boilers. After conducting preliminary experiments and analyses, we performed a 100 kW class proof-of-concept (PoC) test and confirmed the effectiveness of the system.