Reduction of CO2 with IHI's High-Speed Carbonization Technology

Soil carbon sequestration system

IHI Corporation

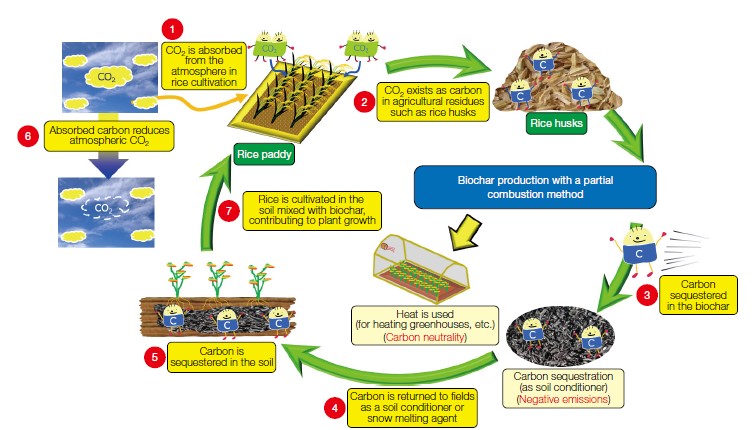

IHI is developing a soil carbon sequestration system to reduce carbon dioxide (CO₂) by producing biochar from plants that have absorbed CO₂ from the atmosphere through photosynthesis and fixing the biochar in the soil. If the heat generated by the biochar production process is used to substitute heat derived from fossil fuels, it can further contribute to CO₂ reduction.

Introduction

In order to slow the current pace of global warming, it is not enough to reduce the amount of newly emitted greenhouse gases; we must also reduce the amount of greenhouse gases already in the atmosphere. CO₂, which has the greatest impact on global warming, can be artificially recovered from the atmosphere and reduced, but most of it is absorbed and reduced from the atmosphere by land plants through photosynthesis. Biochar is produced by carbonizing plants, and then mixed with soil in agricultural fields and other locations to sequester it in the soil. This leads to reduce the CO₂ in the atmosphere. This CO₂ reduction technology can be implemented easily and reasonably within the natural cycle. During biochar production, the feedstock is heated in a low oxygen condition. This releases heat and volatile matter, which yields combustible matter as a byproduct that can be used for multiple purposes. When the combustible matter is burned to generate heat, and the heat can replace fossil fuels in greenhouses, serving as a carbon-neutral heat source and aiding decarbonization. This process can be applied on a large scale, provided that feedstocks are secured, and locations for biochar use are acquired. It would be possible to reduce CO₂ using biomass resources suitable for the region. Consequently, the region could serve as a hub for both energy supply and CO₂ reduction.

IHI is developing a system to sequester carbon into soil as a familiar and immediate CO₂ reduction technology. This system achieves not only negative emissions by producing biochar from plants and sequestering it in the soil but also utilization of the carbon-neutral heat generated during the biochar production process. This system uses a carbonization method with partial combustion in which a part of feedstock is burned, making it possible to decrease the carbonization time from several minutes to just a few seconds.

To implement this system in society rapidly and promote CO₂ reduction, we are conducting various tests to produce biochar from rice husks, which are easily obtainable and can be carbonized without pretreatment, as feedstock, and explore its application to soil.

High-speed carbonization method with partial combustion

The carbonization methods are classified by the heating method, with indirect and direct heating methods.

In the indirect heating method, feedstock is heated inside a ceramic or heat-resistant alloy furnace that is maintained at high temperature. In the furnace, the wall divides the pyrolysis atmosphere, which contains the feedstock, from the heating atmosphere, which places the heater and other equipment, keeping the feedstock and heat supplies divided. This makes the furnace highly controllable but requires expensive heat-resistant materials for the furnace wall. In addition, sealing the inside of the furnace from outside air is important to prevent abnormal combustion in the furnace caused by outside air leaking into the furnace or gas leaking to the outside. A rotating mechanism is often used for the sealing but requires measures to protect the mechanism from the dust generated in the furnace and block the outside air leaking into the furnace, which increases equipment costs.

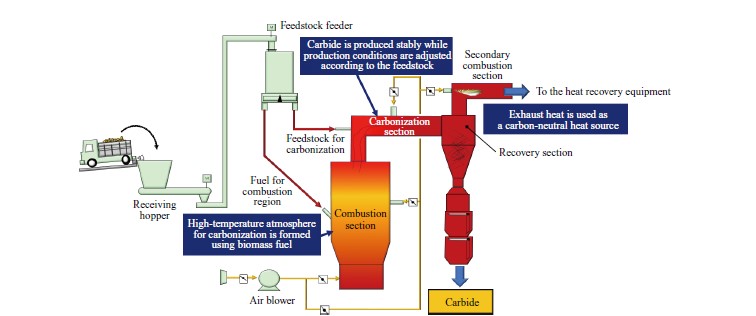

The heating method applied in this system is a partial combustion method, which is different from the indirect heating method and is categorized as a direct heating method. In this method, biochar is produced by supplying heat while incompletely burning feedstocks with air volume Qa, an amount less than air volume Qt, the theoretical combustion air volume required for complete combustion. To sustain combustion in the carbonized area of the furnace, the lower limit of the air supply, Qa is estimated to be 0.6·Qt.

Since inside of the furnace is a combustion atmosphere, this method does not require as high a sealing ability as in the indirect heating method and can use a simple furnace structure. However, it also has a disadvantage where the percentage of carbon remaining in the biochar is lower than in biochar produced with the indirect heating method.

The high-speed carbonization method with partial combustion being developed by IHI enables the production of biochar with less air by supplying the feedstock from two stages; one of them is for atmosphere and the other is for carbonization. The combustion exhaust gas supplied from the combustion section to the carbonization section maintains a temperature higher than the one required for carbonization, and the feedstock newly supplied in this high-temperature gas instantly ignites and releases volatiles. The feedstock igniting and being pyrolyzed at high temperatures enables carbonization within a few seconds in an oxygen-free atmosphere, which was not possible in the past. In addition, the feedstock is carbonized with about half the amount of total air used in conventional systems, reducing the proportion of burned feedstock and increasing the carbon content remaining in the biochar. While utilizing the simple furnace structure of the direct heating method, the issue of low carbon content in biochar is addressed by supplying feedstock in multiple stages.

Start of biochar production from rice husks

The effect on carbon storage is similarly achieved using any kind of plant in principle. In establishing a system to reduce CO₂ by sequestering biochar in soil, the availability of biomass resources and applicability of biochar to the soil must be satisfied in each region. Currently, the benefits of the system are not widely enjoyed due to its low recognition in society.

First, it is worthwhile to apply the system to small-scale, local cases for accumulating achievements. To avoid extra costs in the biochar production process, we placed the highest priority on building a system flow using rice husks, which do not require pretreatment, as feedstock. Rice husks are agricultural residues and available without competing with areas that already use rice husks as livestock feed or bedding, since there is a large quantity of excess. Although availability is seasonal and limited as rice husks are produced when husks of rice are removed, they are readily available as the rice is grown and harvested every year, unlike woody biomass, which requires many years before it can be used.

Currently, we are producing biochar using a prototype machine that can process 2 t of rice husks per day.

Confirmation of biochar application

When biochar is mixed with farmland, it is expected to improve the physical properties of the soil such as permeability and water retention due to voids in the biochar, chemical properties such as soil pH and fertilizer effect, and biological properties such as soil microbial activity. The effect of such improvements would differ depending on the properties of the soil to which biochar is applied as well as the conditions under which the biochar is produced. Furthermore, biochar production conditions affect the biochar’s stability in the soil. Before mixing biochar with the soil, it is necessary to confirm that biochar would not affect the growth of plants. We conducted simple impact assessment of biochar on plant growth before mixing it with the soil in farmland. However, usability in the soil must be ultimately determined on each soil of the farmland where biochar will be used.

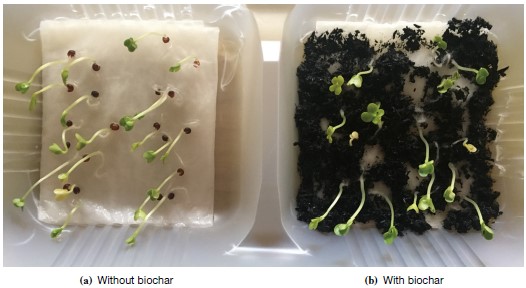

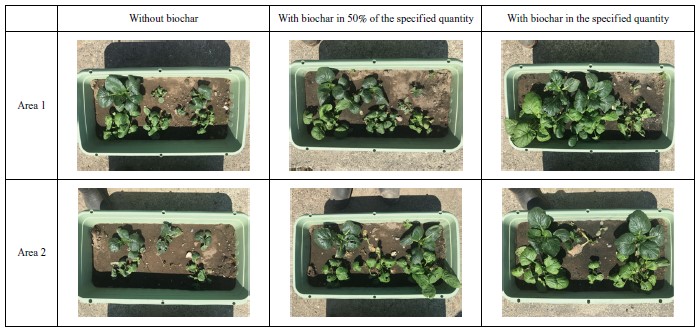

We assessed biochar’s impact on germination using two types of Japanese mustard spinach seeds in a moist seedbed. All seeds germinated regardless of the presence of biochar, and it was found that biochar would not affect germination. Next, we examined the impact of biochar-mixed soil on the growth of Japanese mustard spinach in a small-scale cultivation environment with planters using standard black soil.

The general mix amount and 50% of that amount of biochar was used in testing. The impact of biochar mixture is considered to be easily noticeable as it was assessed in a closed soil environment in planters where there is no interference from the surrounding soil, unlike typical farmland. The test results showed that the Japanese mustard spinach grew better and produced higher yields in soil with biochar than in soil with no biochar. It was obvious that the soil surface was hard without biochar, and that the soil was softer when mixed with biochar. It is considered that the soil’s physical properties improved with the mixed biochar, leading to better root development and enhancing the plant growth. Although this test was conducted in planters, there were no adverse effects on plant growth due to the addition of biochar in the soil.

Activities for the future

Our plan is to carry out a large-scale mixture test on farmland using biochar derived from rice husks produced with this technology. Through the test on the farmland, we will clarify the effectiveness of the technology by assessing the impact of biochar on plant growth in a general plant cultivation environment and the soil. We will also accelerate technological development by applying the technology to the other unused agricultural residues and woody biomass to expand usage.

While the prototype machine does not currently recover heat generated in biochar production, we would like to explore the possibility of using the heat recovered from the boiler for hot water and heating, and combining it with an absorption chiller for cooling as well as power generation depending on the scale of the system.