Small Modular Reactor (SMR) to Contribute towards Decarbonization

Features of NuScale VOYGR SMR and technological development status in IHI

IHI Corporation

In recent years, the development of small modular reactors (SMRs), which have lower output than conventional nuclear reactors, has been actively pursued by various countries. It is considered that SMRs have the next-generation technologies suited to realize a decarbonized society. IHI has been engaged in the technological development of the VOYGR SMR power plants, developed by NuScale Power, LLC. in the United States. This article presents the updated development status of the VOYGR SMR.

Introduction

There has been global concern about climate change, leading to accelerated efforts to implement measures to address it. As the Japanese government has declared its goal of achieving carbon neutrality by 2050, various efforts are required, including the utilization of renewable energy and improvements in energy efficiency.

Among these efforts, nuclear power generation has been attracting renewed attention as a stable energy supply source. According to the statistics from the International Energy Agency (IEA), as of 2021, nuclear power plants generated more than one-quarter of the world’s low-carbon electricity and contributed to reducing carbon dioxide (CO2) emissions by approximately 7 gigatons (Gt) over the past five years. This amount is equivalent to one-tenth of the total CO2 emissions from the global power sector during the five years from 2017 to 2021, continuing to reduce 1 Gt or more of CO2 emissions annually.

In particular, small modular reactors (SMRs) do not emit CO2 and are notable for their safety, factory productivity, and flexibility. This is why SMRs are expected to play a crucial role in achieving carbon neutrality and are being developed in many countries around the world.

Based on the lessons learned from the Fukushima Daiichi Nuclear Power Station accident, efforts to develop nuclear power plants today have focused on improving resistance to natural disasters such as earthquakes and tsunamis, as well as strengthening anti-terrorism measures. Additionally, these efforts include enhancing the safety of nuclear power plants through design improvements to contain radioactive substances within the plant’s premises, even in the event of a core meltdown.

SMRs, which are one of innovative nuclear reactors, have achieved safety improvements through advanced design practices and new safety mechanisms including a natural circulation system. They have also improved their economic performance by simplifying and modularizing systems while maintaining safety.

In contrast to conventional nuclear power plants, which have a power output capacity of approximately 1,000 MW per reactor, SMR power plants have a power output capacity of 300 MW or less per reactor being categorized as next-generation nuclear power plants.

IHI has entered the SMR business by investing in NuScale Power, LLC. (NuScale), a company in the United States, which has been developing SMRs. Over the years, IHI has gained experience and developed technologies in the design, fabrication, construction, and maintenance of nuclear facilities. Building on this experience and these technologies, additional technological development has begun to commercialize SMRs.

This article introduces the features of the VOYGR SMR power plant (VOYGR), developed by NuScale, and the status of technological development for SMRs at IHI as of June 2024.

Features of VOYGR

NuScale is one of the leading companies in SMR development, and VOYGR, developed by NuScale, is the first SMR to evaluate its safety from the U.S. Nuclear Regulatory Commission and be granted a design certification. The commercial operation of two VOYGR units in the United States is expected to begin in 2029, one in Ohio and the other in Pennsylvania. Additionally, amid the growing need for decarbonization and energy security on a global scale, various countries, primarily in North America and Europe, have moved forward with plans to introduce SMRs. An example of this trend is the commencement of front end engineering design (FEED) work for the Doicești Power Plant in Romania.

With a small reactor core, an SMR can reduce the affected area in the event of an accident. Additionally, by allowing natural circulation to cool the reactor core during normal operation, an SMR can eliminate the need for large-scale pumps and simplify the facility. Furthermore, an SMR can be constructed by fabricating units (modules) with pre-assembled components in a factory, transporting them to the site, and installing them without being affected by weather conditions. This approach is expected to achieve high quality, shorten the construction period, and improve economic performance through mass production.

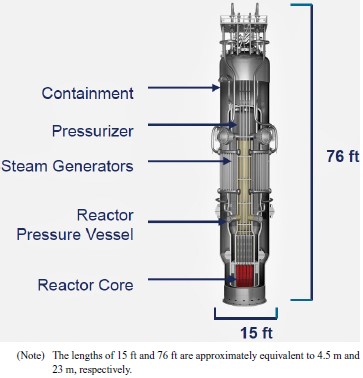

The nuclear reactor of the VOYGR, called the NuScale Power Module (NPM), consists of a reactor pressure vessel, a steam generator, a pressurizer, and a containment vessel, all contained in one package. Thus, an NPM simplifies facility design by eliminating the need for reactor cooling pumps, large-diameter piping, and other ancillary equipment typically required for large-scale reactors.

Up to 12 units of NPM, each with a power output capacity of 77 MW, can be connected to achieve a total power output of up to 924 MW. VOYGR’s standard lineup of NPMs includes a 6-unit type with a 462 MW output and a 4-unit type with a 308 MW output.

Each NPM has an independent power generation system designed for individual and flexible operation. Therefore, NPMs can provide an effective regulated power supply to compensate for the large fluctuations in power supply from renewable energy sources.

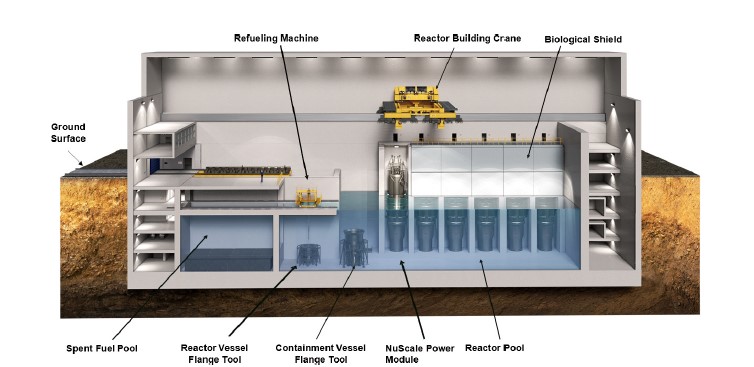

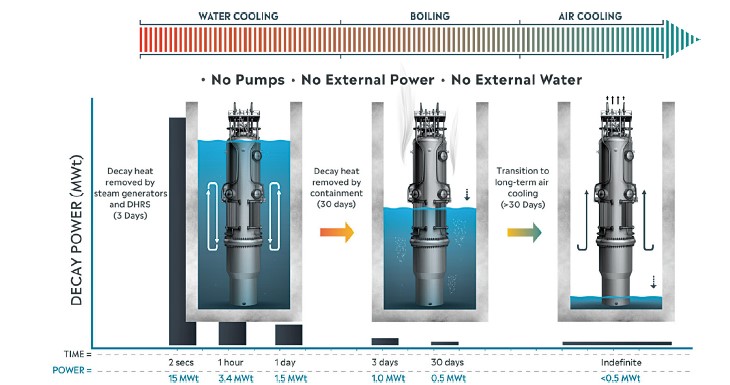

Each NPM is installed in a large reactor pool, allowing it to be cooled for an extended period in the event of an accident without the need for operator intervention or external power. The reactor pool can cool the decay heat of up to 12 units of NPM for more than 30 days. After the water in the reactor pool evaporates, the NPMs can be continuously and indefinitely cooled by air.

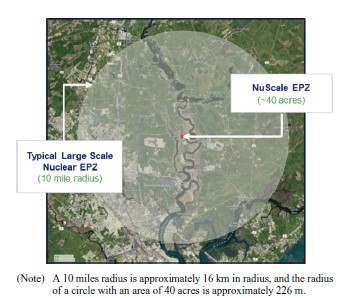

Conventional nuclear power plants have emergency planning zones in their vicinity, which are areas identified for implementing emergency responses in the event of accidents or other incidents. In the United States, people within an approximately 10 mile (16 km) radius of a power plant are primarily required to evacuate and shelter indoors in the event of an emergency situation. With its advanced safety features, VOYGR is expected to significantly reduce the size of the emergency planning zone compared to conventional large-scale reactors, limiting it to the area within the power plant premises, thus facilitating more flexible site selection.

Technological development status in IHI

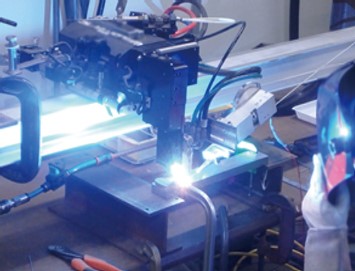

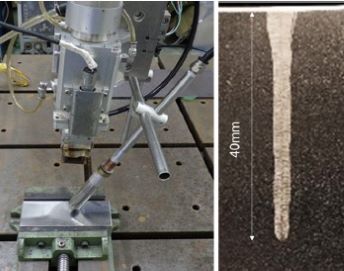

IHI has been developing technologies for fabricating and inspecting containment vessels, which are one of the main components of NPMs. High-strength special materials that have rarely been used in conventional nuclear facilities are being applied to the containment vessels. We have also been addressing advancements in welding technology to achieve both quality assurance and improved workability. The submerged arc welding method has been widely used as a high-performance welding technique for conventional large-scale pressure vessels. However, it was found that when this method is applied to the welding of the special materials used in VOYGR, it results in a reduction in toughness, an indicator of a material’s resilience. Therefore, IHI developed a new gas-metal arc welding technique that achieves high-toughness welding while maintaining work efficiency.

Additionally, since VOYGR can accommodate up to 12 units of NPM, it is essential to develop techniques that enhance the capacity for mass production and efficiency of NPM fabrication to promote the global adoption of VOYGR. To this end, with a focus on the future mass production of NPMs, IHI has advanced technological development to enable laser welding to be used in mass production alongside improvements in the above-mentioned arc welding technique. Laser welding is expected to provide faster welding with reduced distortion.

IHI has evaluated the safety and structural feasibility of NPMs in preparation for their introduction in Asian countries, including Japan, where seismic conditions are more severe than in the United States.

Future prospects

Since the 1950s, IHI has been a leading manufacturer of nuclear equipment. Building on its extensive track record, IHI will support the advancement of SMR technologies of NuScale, enhancing their safety and efficiency, thereby contributing to the achievement of carbon neutrality and a stable energy supply.

Additionally, with no prospects for new nuclear power plant construction in Japan, maintaining nuclear technologies has become a significant challenge. Building on its accumulated manufacturing and engineering expertise, as well as the experience gained through the technological development of NuScale’s SMR, IHI will continue to maintain and improve technologies and contribute to enhancing nuclear safety and fulfilling its role as a leading manufacturer of nuclear equipment.