Achieving Carbon Neutrality in Chemical Industry

Development of an ammonia single-firing burner for naphtha cracking furnaces

IHI Corporation

To achieve carbon neutrality in the chemical industry, IHI developed a burner fueled only by ammonia for naphtha cracking furnaces to reduce CO₂ emissions from such furnaces. Development was conducted in a basic combustion test furnace at the Development & Demonstration Park (D&D Park) in the IHI Aioi Works, and it was confirmed that the burner satisfied the specified performance.

Introduction

The reduction of greenhouse gas emissions is a common issue worldwide in any field to curb global warming and create a sustainable society. In Japan, the chemical industry is the second largest emitter of carbon dioxide (CO₂) in industrial sectors after the steel industry, and there are intensified discussions among the government and companies to promote decarbonization.

Plastic, a petrochemical product, is manufactured from olefins (such as ethylene and propylene) obtained by heating naphtha refined from petroleum to 800°C or higher and pyrolyzing it. The pyrolysis process is carried out in the naphtha cracking furnace, which is the main equipment in the petrochemical complex. The naphtha cracking furnace is mainly fueled by by-product gas, which mainly contains methane, generated during the process, and emits a large amount of CO₂ during operation.

Ammonia (NH3) is known as a carbon-free fuel which does not emit CO₂ when burned, and IHI has been developing technology to use ammonia as a fuel to achieve carbon neutrality in the industrial and power generation fields. The application of this ammonia fuel conversion technology to naphtha cracking furnaces is expected to reduce CO₂ generated in the pyrolysis process and to significantly contribute to achieving carbon neutrality in the chemical industry.

Development of an ammonia single-firing burner

IHI is working to study for building an ammonia supply chain jointly with Idemitsu Kosan Co., Ltd. at Idemitsu Kosan’s Tokuyama Complex (Shunan City, Yamaguchi Prefecture). In February 2024, the companies carried out a demonstration test of ammonia combustion at the existing naphtha cracking furnace in the complex, and achieved operation with an ammonia combustion rate of over 20%. In line with the conditions of the demonstration test, IHI developed an ammonia single-firing burner for naphtha cracking furnaces.

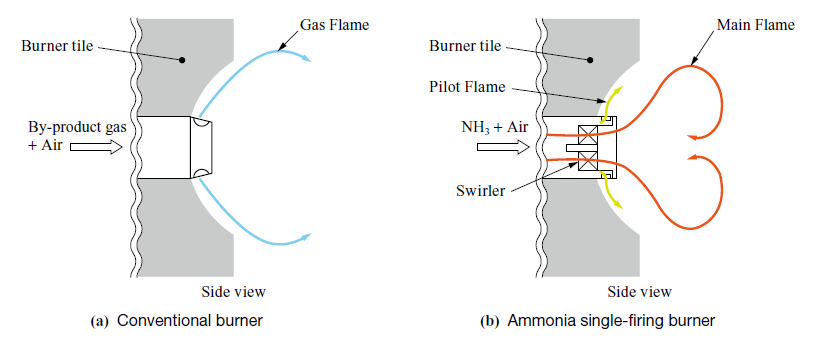

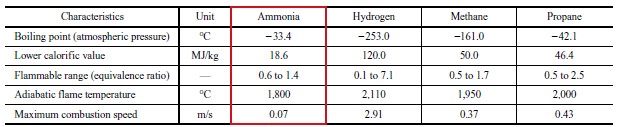

The naphtha cracking furnace is mainly fueled by methane-based by-product gas, which has a relatively high calorific value and combustion speed, while ammonia has a low combustion speed as shown in the table. In order to minimize modifications to the furnace, the heat input per ammonia single-firing burner is approximately 1.5 times that of a methane burner due to the size of the burner and the limited installation location. This may cause the flame to extend forward and damage the reaction tube. Furthermore, ammonia contains nitrogen (N) in its molecules, which may emit a large amount of nitrogen oxides (NOx) in some combustion conditions. Therefore, in developing an ammonia single-firing burner, it is necessary to enhance flame dispersion (so the flame does not extend) and reduce NOx emissions.

To determine the burner to be used in the demonstration test, we examined in advance burner shapes with high flame dispersion capabilities. To compare the characteristics, we fabricated burners with different shapes and conducted a combustion test at the test furnace. The combustion test was carried out at the basic combustion test furnace (1 MWth) at the Development & Demonstration Park (D&D Park) in the IHI Aioi Works.

In the combustion test, we inspected whether or not ammonia leaked out of the system from around the burner and confirmed that the burner was structurally safe. In addition to ammonia’s flame dispersion, we also measured the variable range of combustion loads and emissions of NOx and unburned ammonia to evaluate the burner’s performance. The combustion test enabled us to choose an optimal shape and confirm that the chosen burner satisfied the specified performance.

Future plan

In order to achieve carbon neutrality in naphtha cracking furnaces, increasing the ammonia combustion rate will be a future technological challenge. For example, the flame temperature of ammonia is about 200°C lower than that of methane and other hydrocarbons. Therefore, heat input to the reaction tube decreases as the combustion rate increases, which may affect the yield of cracked products. The emission characteristics of NOx and unburned ammonia in the high ammonia combustion rate may differ from those in the previous tests, and methods to adjust combustion should also be considered.

IHI has been a pioneer in the development of ammonia combustion technology to achieve carbon neutrality. We will further advance the technologies and provide solutions to various challenges that emerge in actual operation to contribute to decarbonization of the world.