Successful Demonstration Test of Ammonia Firing Conducted at Commercial Power Station

Results of demonstration test for ammonia 20% firing at Hekinan Thermal Power Station Unit 4

IHI Corporation

The IHI Group has made efforts to introduce ammonia, which does not emit carbon dioxide (CO₂) during combustion, as a fuel for pulverized coal-fired boilers and gas turbines, providing an effective means to achieve carbon neutrality at thermal power stations. Technological developments have been made to address the challenges of achieving stable and low nitrogen oxides (NOx) combustion posed by the properties of ammonia. As the culmination of its development efforts, IHI, in collaboration with JERA Co., Inc., successfully conducted a demonstration test of ammonia 20% firing at Unit 4 of the Hekinan Thermal Power Station of JERA, marking a significant first step towards commercialization.

Introduction

Currently, various industries have devised and implemented measures to reduce the emissions of greenhouse gases in an effort to mitigate global warming. In thermal power generation facilities, ammonia has been proposed as an alternative fuel that does not emit carbon dioxide (CO₂). However, since ammonia has low combustibility and raises concerns about nitrogen oxide (NOx) emissions, the key development challenge has been to achieve stable combustion with low NOx emissions in commercial facilities.

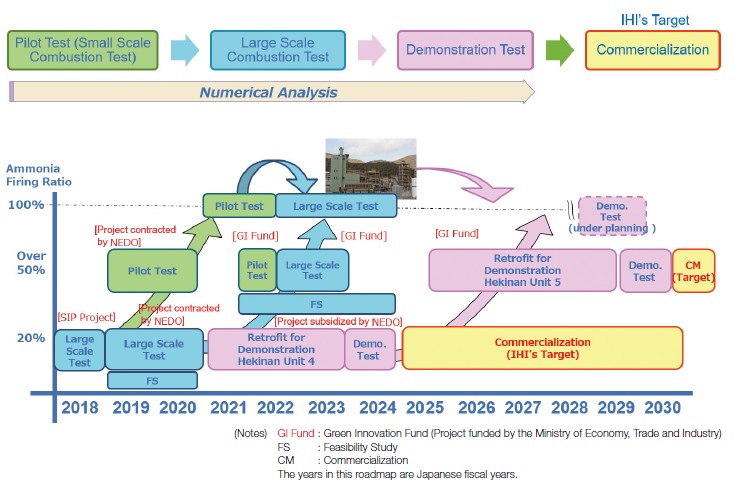

IHI focused on the use of ammonia as an alternative fuel and started developing ammonia combustion technologies in the mid-2010s. IHI then discovered the potential for ammonia combustion through investigation and research on its use in the boiler of the existing coal-fired thermal power stations in FY2017 and FY2018, as part of the Cross-ministerial Strategic Innovation Promotion Program (SIP) led by the Cabinet Office of Japan. Subsequently, a detailed study commissioned by the New Energy and Industrial Technology Development Organization (NEDO) was conducted in FY2019 and FY2020 on ammonia combustion, based on the operational conditions of the boiler at JERA’s Hekinan Thermal Power Station in Aichi Prefecture ( *1). After that, a subsidized project for the demonstration test of ammonia 20% firing at Hekinan Thermal Power Station was conducted from FY2021 to FY2024 ( *2) . The term “ammonia 20% firing” means that ammonia accounts for 20% of the heat input into the boiler, with the remaining 80% supplied by coal. Here, the firing ratio is equivalent to the heat input ratio.

This article presents the modified facilities, contents and results of the demonstration test on ammonia 20% firing at Unit 4 of Hekinan Thermal Power Station (hereinafter referred to as “Hekinan Unit 4”). IHI also carried out a demonstration project firing fuel containing 50% or more ammonia at Hekinan Thermal Power Station (Green Innovation Fund Project, JPNP21020, subsidized by NEDO) and the development of a burner specifically for ammonia, both of which will be published in other articles.

-

*1Technological development of carbon recycling and next-generation thermal power generation / Technological development of next-generation thermal power generation / Next-generation thermal power generation technology promotion project / Advance research of ammonia firing thermal power generation technology / Research and development of ammonia firing technology for multi-burners in pulverized coal-fired boilers (JPNP16002)

- *2“Development of Technologies for Carbon Recycling and Next-Generation Thermal Power Generation / Research, Development, and Demonstration of Technologies for Ammonia Co-Firing Thermal Power Generation” project / Demonstration research firing 20% ammonia fuel at a 1,000,000 kW-class coal-fired power plant (JPNP16002)

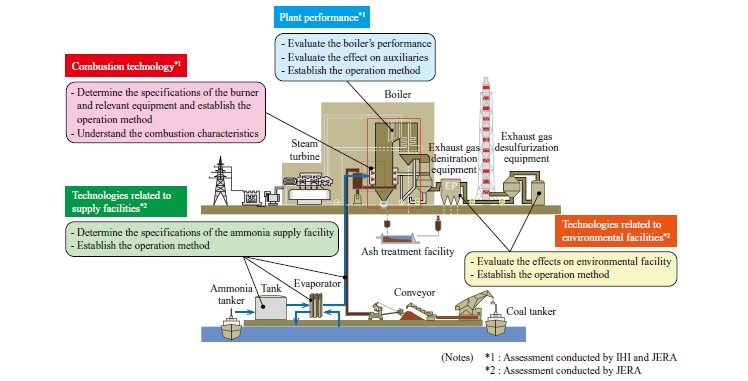

Modified facilities for demonstration test

To burn ammonia fuel with a coal-fired boiler, it is necessary to partially modify the boiler and install an additional ammonia supply facility. The following introduces an example of such activities at the Hekinan Unit 4 facility, used for the demonstration test for firing 20% ammonia fuel.

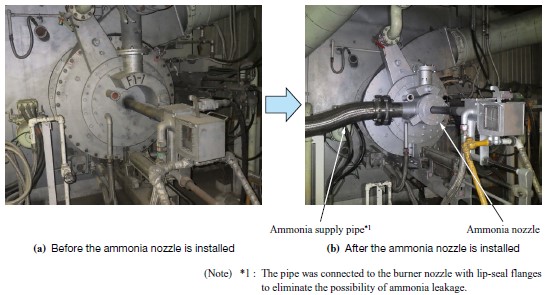

The modification for the boiler is only to install an additional ammonia nozzle to the existing burner. Additional piping and valves will be needed to supply ammonia, of course, but if the ammonia firing ratio is around 20%, it is possible to reduce CO₂ emissions by 20% using ammonia simply by modifying the burner around the boiler. However, this may not be the case for all plants, and depending on the condition of the facility and the margin of capacity, it may be necessary to make modifications in addition to those made to the burner.

The IHI’s burner equipped with an ammonia nozzle can operate purely on coal when ammonia is not used, exactly the same as in its pre-modified state. This enables the boiler to maintain operational capacity regardless of the ammonia supply. Hekinan Unit 4 has 48 burners, each of which is equipped with an ammonia nozzle. There are six coal pulverizer mills that supply coal to the burners. Five of them are usually in operation (remaining one is backup), and it is possible to maintain an ammonia firing ratio of 20% for all mill operation patterns.

The development of the ammonia burner started with a combustion test at a small combustion test furnace for internal research (refer to “Development of Co-Firing Method of Pulverized Coal and Ammonia to Reduce Greenhouse Gas Emissions” IHI Engineering Review, Vol. 53, No. 1, 2020 ). Based on the test results and numerical analysis results, we examined from which area around the burner ammonia should be supplied, and started a test using a large combustion test furnace based on the findings obtained from the study of reducing NOx emissions from existing coal burners. It was difficult to evaluate the validity of the test results as the research was being conducted in a novel field, and it was necessary to verify the accuracy of data by repeating the test (the above-mentioned SIP project). Based on the obtained data and accumulated findings, we established design guidelines for ammonia burners through the examination of a specific burner structure and combustion tests with this structure (project contracted by NEDO from FY2019 to FY2020). The ammonia burner at Hekinan Unit 4 was designed using these guidelines (project subsidized by NEDO from FY2021 to FY2024).

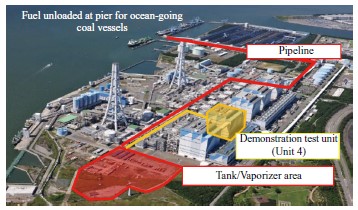

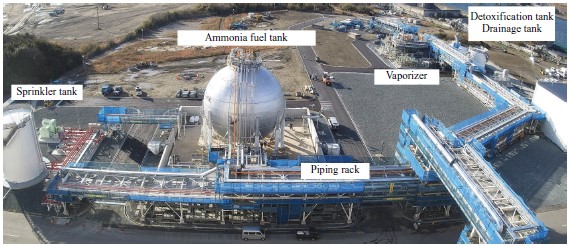

Next, we will introduce the ammonia supply facility. Overall, the facility receives and stores liquid ammonia, and vaporizes it with the vaporizer to supply ammonia gas to the boiler. Specifically, the following equipment is installed:

- Ammonia fuel receiving equipment (such as a loading arm)

- Ammonia fuel tank

- Ammonia fuel BOG compressor (BOG : Boil Off Gas, gas vaporized in the tank)

- Detoxification equipment

- Ammonia fuel discharging pump

- Ammonia fuel vaporizer

- Ammonia fuel vaporizer seawater pump

- Ammonia fuel superheater

- Ammonia fuel piping and valves for liquid or gas to connect the above equipment

Ammonia is widely used in various industries, and the technologies to handle both liquid and gaseous ammonia are well established. Therefore, the equipment used here is an extension of conventional technology and does not differ significantly from existing ammonia-handling facilities. However, there have been no examples of facilities that specialize in receiving and discharging ammonia as a fuel. In particular, special attention has been paid to enlarging capacity of the facility and ensuring safety.

While the ammonia fuel tank for Hekinan Unit 4 is used as a buffer tank, a higher capacity tank will be used when it is commercialized in the future. The IHI Group is also developing technologies related to increasing tank capacity (refer to “Realizing Large-Volume Ammonia Tanks and Establishing New Test Method” IHI Engineering Review, Vol. 57, No. 1, 2024).

Contents of demonstration test of ammonia 20% firing in commercially operating boiler

The purpose of the demonstration test of ammonia 20% firing at Hekinan Thermal Power Station is as follows.

Since the use of ammonia as a fuel was proposed as a measure to reduce CO₂ emissions at thermal power systems, we have conducted verification and examination through combustion tests at test facilities and analysis. It is necessary to demonstrate the technology with commercially operating power plants and establish the technology for commercialization.

For that purpose, we determined reasonable specifications for boiler-related equipment and ammonia supply facility and carried out the demonstration test firing 20% fuel at an existing 1,000 MW-class coal-fired power station (Hekinan Unit 4) to understand operating conditions and other characteristics and identify and solve issues in actual operation. This enabled us to establish the technology to use ammonia as a fuel at thermal power plants for commercialization.

To realize this, we have installed the above-mentioned facilities and prepared for a demonstration test. Our goal in the demonstration test is to (1) identify issues for the commercialization of ammonia combustion technology, such as characteristics and constraints for the entire plant when ammonia 20% firing is performed, and (2) establish the ammonia 20% firing technology based on (1).

The demonstration test period was set to approximately three months to establish ammonia 20% firing operations and to conduct various tests for the evaluation of combustion characteristics.

Furthermore, since the power station had never used ammonia as a fuel and there were no precedent cases, IHI dedicated ample time to ensure safety through discussions and consultations with JERA and subcontractors. JERA, the power station operator, conducted a risk assessment covering various safety and disaster prevention aspects when planning the disaster prevention facilities of the power station and implemented measures based on the assessment results. Additionally, to enhance emergency preparedness, JERA collaborated with local municipalities. One example was disaster prevention drills with the jurisdictional fire department. With the aforementioned preparations in place, the demonstration test was conducted safely without any accidents or incidents.

Demonstration test results

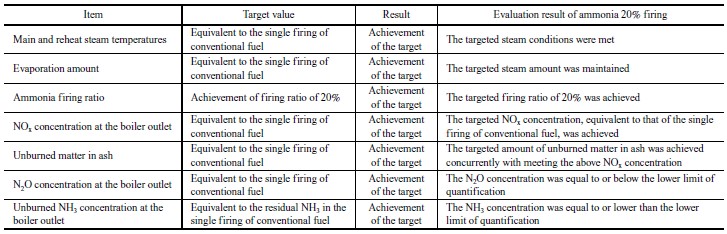

Ammonia combustion began on April 1, 2024, and ammonia 20% firing at a rated output of 1,000 MW was successfully achieved as planned on April 10, 2024.

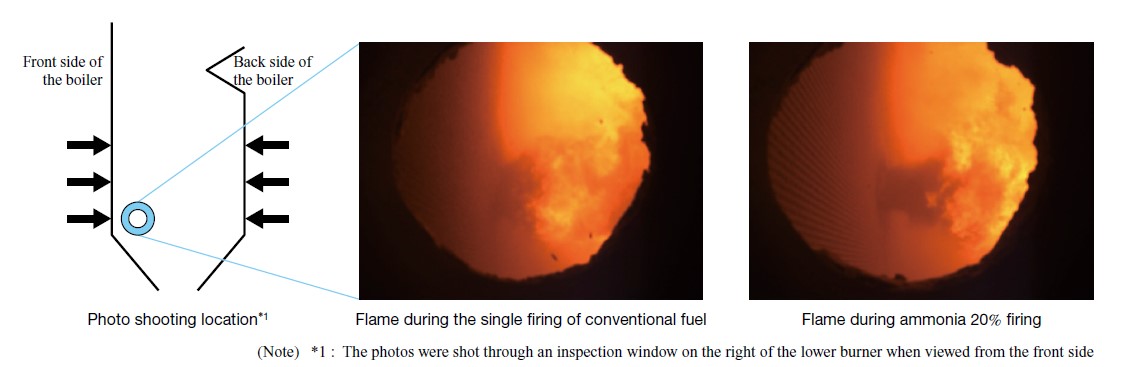

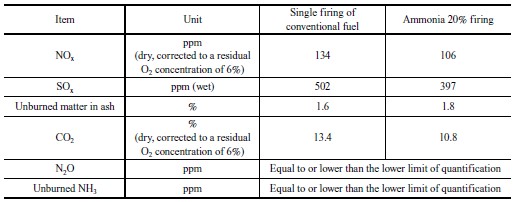

Key demonstration test results, particularly those related to combustion performance, are summarized in the combustion performance results list. NOx emissions, the primary concern associated with ammonia 20% firing, were confirmed to be equal to or lower than those from the single firing of conventional fuel. Specifically, depending on operating conditions, NOx emissions from ammonia 20% firing were similar to those from the single firing of conventional fuel although they were lower in many cases. Therefore, ammonia 20% firing is assessed to have NOx emission characteristics equivalent to those of conventional fuel single firing. Additionally, the amount of unburned matter in ash, which is inversely related to NOx emissions, from ammonia 20% firing was assessed to be equivalent to that from the single firing of conventional fuel. This confirmed that ammonia 20% firing can simultaneously suppress NOx emissions and the amount of unburned matter in ash to levels equivalent to those of conventional fuel single firing. In terms of greenhouse gas emissions, ammonia 20% firing achieved approximately a 20% reduction in CO₂ emissions, as targeted when the demonstration test was planned. The emissions of nitrous oxide (N2O), which has a high greenhouse effect, were equal to or lower than the lower limit of quantification. Similarly, ammonia 20% firing achieved approximately a 20% reduction in sulfur oxide (SOx) emissions and the amount of unburned ammonia (NH3) was equal to or lower than the lower limit of quantification. Accordingly, the demonstration test yielded favorable results in terms of both combustion and environmental performance. The factor contributing to these favorable combustion performance results, particularly the suppression of NOx emissions to levels equivalent to those from the single firing of conventional fuel, is believed to be the understanding of the ammonia combustion mechanism and its integration with technologies that have long been developed for reducing NOx emissions from coal and other conventional fuel combustion. This achievement in establishing technologies for ammonia combustion as a new fuel is expected to accelerate the further advancement of ammonia combustion technologies, including the increase of ammonia firing ratios and the introduction of ammonia combustion technologies to other industrial sectors.

Next, the following discusses the results of the test conducted to confirm the plant operability of ammonia 20% firing. A test to verify the injected ammonia mass flow balance in the denitrification process was conducted during the demonstration test. The modified power plant facilities include denitrification equipment that injects ammonia through an injection hole positioned upstream of the denitrification catalyst in the gas flow direction, with the injected ammonia flow balance adjusted to optimize denitrification efficiency. Thus, the test was conducted to confirm the effects of ammonia 20% firing on the ammonia mass balance in the nitrification process. As a result, ammonia 20% firing did not alter the NOx distribution and, therefore, required no additional adjustment to the ammonia injection amount. Regarding the load change test, controllable operation was confirmed to be possible by conducting load changes similar to those during the operation of the existing power station. Additionally, it was confirmed that the facilities could safely handle the load reduction to a targeted level during the ammonia supply emergency cut-off test. The changes in the process values associated with the ammonia supply cut-off operation were within the planned range, and it was confirmed that the facilities could be safely shut down without any leakage. Accordingly, it was confirmed that ammonia 20% firing ensures plant operability equivalent to the single firing of conventional fuel. Moreover, the above findings were obtained with the steam conditions of the single firing of conventional fuel consistently applied to ammonia 20% firing.

The demonstration test confirmed that ammonia 20% firing is operational, because it can ensure combustion performance and plant operability equivalent to the single firing of conventional fuel, without any disadvantages. To summarize the demonstration test, the test items and evaluation results are presented in the overall test result summary table. The demonstration test successfully met all test objectives and achieved the predetermined outcomes for technical challenges related to combustibility, NOx emissions, operability, safety, and other aspects.

Future development

These demonstration test results have garnered worldwide attention. Introducing ammonia with a firing ratio of 20% is regarded as the fastest and economical solution for achieving maximum CO₂ emission reductions. Therefore, the successful demonstration of ammonia 20% firing this time is expected to accelerate the commercialization of ammonia use significantly. IHI will support customers in their efforts to implement ammonia in practical applications.

Additionally, regarding ammonia firing at higher firing ratios, which has been developed alongside 20% firing, IHI completed the ongoing feasibility study for a demonstration project (the development of burners for high ammonia firing ratios has already been finalized). IHI is preparing for the demonstration test as the next step, which will include the planning, modification work, ammonia firing testing and evaluation of the test results.

Furthermore, IHI is developing combustion technology for ammonia single firing. For example, we have successfully visualized the flame of ammonia single firing with a special camera and filter although flame is not visible in blight condition. And then, we will complete the development of a burner for ammonia single firing by the end of FY2024. And the application of the burner to small boilers and industrial furnaces that match the performance of the individual burner is also under consideration.

This article presented the modified facilities, contents and results of the demonstration test at Hekinan Unit 4, a groundbreaking achievement for prospective users of ammonia as a fuel. IHI will also advance the establishment of ammonia supply chains by carrying out specific initiatives that have been prepared in collaboration with various countries, companies, and organizations.

Through these efforts, IHI will contribute to reducing CO₂ emissions by developing technologies to transition from conventional fuels to ammonia, thereby continuously providing diverse solutions to meet various societal needs in pursuit of carbon neutrality by 2050.