Material Handling System

Logistics Solution

Offering the optimal logistics solution for our customers by leveraging the experience we have acquired across all fi elds, including material handling centers and material handling storage.

Based on the knowledge we have acquired as a comprehensive logistics manufacturer, we organically combine hardware and software technologies to pursue lower costs and higher reliability in the logistics and material handling fi elds.

Backed by a myriad of technical resources, we propose the optimal logistics solution for customers.

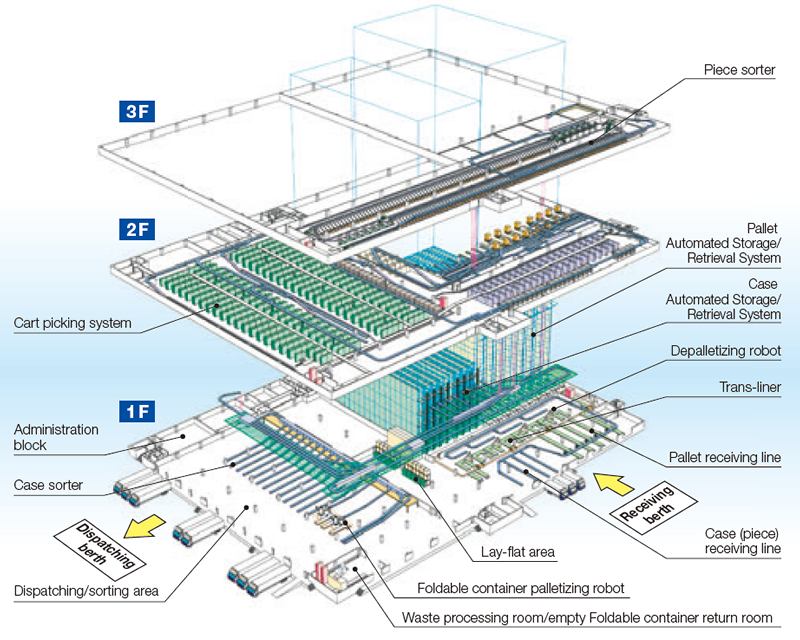

Example of Distribution Center

Logistic solutions offered by IHI Group

- Investigation/analysis

- Concept design

- Optimization of material handling fl ow and operation foot prints

- Selection of material handling devices that consider throughput balance

- Examination of effi cient personnel allocation

- Linkage of overall system control and host systems

Storage

Achieving high economic performance with outstanding results and advanced technology

Standard Automated Storage/Retrieval System

Rackpack/Robostack

Slim and compact

A new design for the extreme minimization of unnecessary gaps. Overwhelming

storage effi ciency

High-speed & smooth

Equipped with original motion control software. Gentle and quick acceleration to

maximum speed

Energy-saving & ecological

Signifi cant reduction of power consumption as a result of the lightweight body

and utilization of regenerative power

Auto-Stack Building – Building Integrated-type

Automated Storage/Retrieval System

- Automated Storage/Retrieval System leveraging the comprehensive technical

capabilities of the IHI Group - Excellent space effi ciency and short lead-time

- Outstanding results including refrigerated storage, hazardous materials

handling, vehicle storage, etc.

Rackpack

Rackpack

Robostack

Conveyance

Quiet, high-speed unmanned conveyance for a variety of logistics types

Unmanned Conveyance Systems

Smooth & shockless

Inverter control enables smooth, shock-free sending, stopping and acceleration

Variety transfer equipment

Fully-automatic loading/unloading is possible with conveyors, push-pulls, lifters and more

High standard footwork (AGV “Fact Liner” )

Both guidance methods (magnetic/laser) are capable of forward and backward movements, as well as spinning, turning, lateral motions, and effi ciently navigating complicated routes.

High speed + high accuracy (RGV “Trans-liner”)

Amongst the industry’s best in regards to maximum speed, stopping accuracy, and smooth acceleration

Fact Liner (AGV)

Trans-liner (RGV)

Sorting & Picking

Reliable, speedy picking system

Shuttle & Server

Multi-story structure type High performance case Automated Storage/Retrieval System

- By combining high loading/unloading capability with the high-density storage capability of Automated Storage/Retrieval System, the full automation oftemporary storage and high-speed/accurate sorting is achieved

- Maintains stable operation even with a high operating rate due to a robust structure. Energy savings and open space are achieved through a lean structure and through weight reduction

Shuttle & Server

Shuttle & Server

IHI Depalletizing system (AADS)

IHI launched the New depalletizing system controlled by our original Deep-leaning AI system.

It’s the worlds first AI depalletizing system and its cognitive performance improved by 30%

- Pre-registration of data and teaching are unnecessary by object recognition technology by AI.

- It is possible to correspond even pallets loaded with loads of various sizes.

- Optimize the grip point and arm route. Improved throughput by 30%.

IHI Depalletizing system(AADS)

System

Construction / Set up / Control

From construction to set up of machinery, test running of machinery and technical support after delivery, we try to provide value added products with safety and speed. Technicians who have plentiful experience for logistics plant construction both for domestic market and overseas, will provide matching service for each customer site, which will connect to timely operation. Moreover, after operation is started, high quality service will provided continuously by our service department.

Construction

Assembly construction of stocker crane which is the main part of auto-warehouse system.

Set up & test drive

Checking various safety system(sensor etc)

Setting up transfer system for handling products